Here’s why: Motors account for 70% of industrial electricity use, and pumps alone make up 30% of that. Most pumps run at full speed unnecessarily, wasting energy. VFDs adjust motor speed to match actual demand, saving money and reducing wear on equipment.

Key Insights:

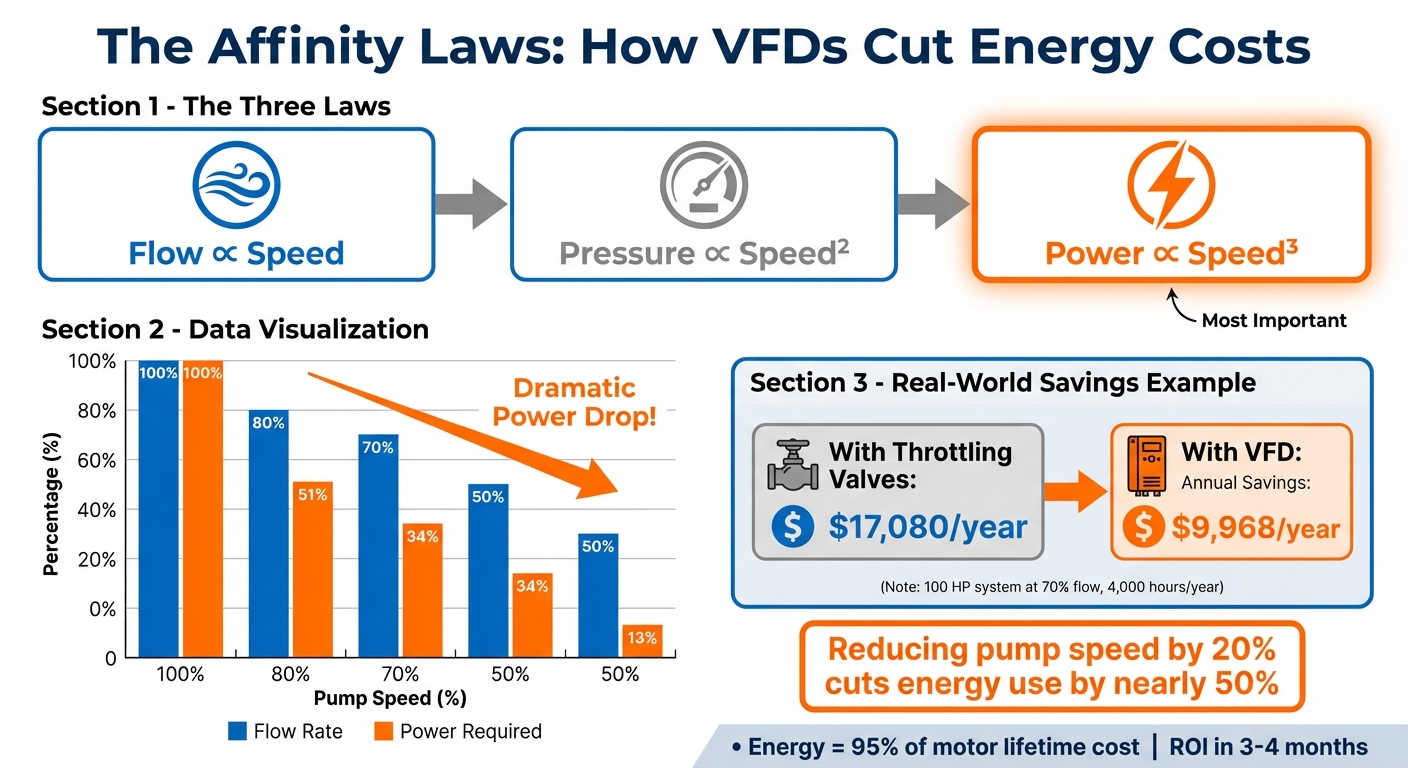

- Energy Savings: Reducing pump speed by just 20% can cut energy use by nearly 50%.

- Cost Efficiency: A VFD can save thousands annually by replacing inefficient throttling valves.

- Extended Equipment Life: Smooth motor starts and reduced vibration lower maintenance needs.

- Better Control: VFDs fine-tune flow, pressure, and speed for precise system performance.

Why It Matters:

Energy costs make up 95% of a motor’s lifetime expense, so optimizing usage with VFDs delivers rapid payback – often in 3-4 months. Whether it’s a single pump or a multi-pump system, VFDs offer smarter, more efficient control for industrial operations.

Read on for practical setup tips, maintenance advice, and solutions to common challenges like low-speed operation and harmonic distortion.

The Affinity Laws and Variable Frequency Drives: A Lesson in Savings

Energy Savings with VFDs: The Affinity Laws

VFD Energy Savings: Pump Speed vs Power Consumption Chart

The Affinity Laws Explained

The Affinity Laws describe how changes in pump speed affect flow, pressure (head), and power consumption. These principles are key to understanding how Variable Frequency Drives (VFDs) can significantly reduce energy usage.

Here’s the breakdown: Flow is directly proportional to pump speed – cut the speed in half, and flow drops by half. Head (pressure) is proportional to the square of the speed – reduce the speed by 50%, and the head falls to just 25% of its original value. The most impactful relationship is with power consumption, which is proportional to the cube of the speed. This cubic connection is where the major energy savings come into play.

"The affinity laws can determine the system performance for centrifugal devices, defining both theoretical load requirements and possible energy savings"

To see how this works in practice, take a look at the table below:

| Pump Speed (%) | Flow Rate (%) | Horsepower Required (%) |

|---|---|---|

| 100 | 100 | 100 |

| 80 | 80 | 51 |

| 70 | 70 | 34 |

| 50 | 50 | 13 |

The numbers highlight the dramatic reduction in power required as pump speed decreases. This cubic relationship is the foundation of VFD energy savings, as these devices fine-tune motor speeds to match system needs.

How VFDs Use the Affinity Laws to Save Energy

VFDs capitalize on the Affinity Laws by adjusting motor speeds in real time to meet actual system demand. Instead of running pumps at full speed and relying on throttling valves to control flow – an inherently wasteful process – VFDs reduce motor speed directly. This approach shifts the pump curve downward, cutting both flow and pressure while maintaining efficiency.

Because power consumption drops exponentially with speed, even modest reductions lead to significant savings. For instance, in a 100 HP system operating at 70% flow for 4,000 hours annually, throttling valves would result in energy costs of $17,080. By contrast, using a VFD would lower that cost to $9,968 – saving over $7,000 each year.

"In centrifugal pump applications with low head pressures, VFD controllers will typically save more than 50 percent of the energy used"

VFDs perform exceptionally well in systems where friction head dominates over static head, enabling the pump to operate closer to its Best Efficiency Point (BEP) across a wide range of flows.

In systems that frequently operate below 70% flow, the financial and energy benefits become even more pronounced:

"Energy and the associated cost savings are the main motives for using VFDs. When a drive is applied to a fan or pump, the return on investment can be realized in as few as three to four months"

Benefits of VFDs for Centrifugal Pump Systems

Variable frequency drives (VFDs) offer more than just energy savings – they also bring significant cost reductions and operational improvements to centrifugal pump systems.

Energy Efficiency and Cost Savings

One of the standout advantages of VFDs is their ability to cut energy waste by aligning motor speed with actual demand. Considering that energy use accounts for about 95% of a motor’s total life cycle cost, while the upfront investment is only 2%, the financial benefits of VFDs become hard to ignore.

Here’s an example: A 100-horsepower pump motor running non-stop for a year could rack up energy costs exceeding $40,000. By switching to VFDs, the savings are clear. For instance, at 70% flow over 4,000 hours, valve control costs around $17,080, but with VFDs, that drops to $9,968 – saving over $7,000 annually. VFDs also reduce motor starting current by a factor of 4:1 compared to traditional across-the-line starting. Plus, they deliver a near-unity power factor (0.97 to 0.98), which helps operators sidestep utility penalties that come with poor power factor, typically ranging from 0.72 to 0.87 for standard motors.

Beyond energy savings, these features also help reduce mechanical stresses, which can extend the lifespan of your equipment.

Less Wear and Tear on Equipment

VFDs are not just about saving money – they also protect your equipment. Traditional across-the-line starts can result in an inrush current that’s 600% of the rated value, causing serious mechanical strain. VFDs solve this problem by gradually ramping up voltage and frequency, avoiding the damaging surges and ensuring smooth acceleration with S-ramp functions.

"This reduction in vibration significantly extends the life of the pump seals and the time between costly and, in many cases, unscheduled maintenance events." – Alex Harvey, Director of AC and DC Drives, Control Techniques – Americas

Operating at reduced speeds also lowers system pressure, easing stress on components like impellers, seals, bearings, and pipe joints. VFDs can even be programmed to skip certain frequencies that align with the system’s natural resonances, which minimizes vibration and prevents damage. By keeping pumps operating close to their Best Efficiency Point (BEP), VFDs reduce internal turbulence and vibrations that can wear down components over time.

Better Process Control

In addition to energy savings and durability, VFDs improve process control by offering precise, automated management of variables like pressure, flow, and fluid levels. Using Pulse Width Modulation (PWM) technology, VFDs can adjust motor speed with high accuracy. Built-in PID controllers further simplify operations by automatically responding to demand changes, handling tasks like maintaining tank levels and system pressure without requiring external controllers.

"Rather than constantly run the motor at full speed, variable frequency drive (VFD) systems… monitor system characteristics like pressure and control the motor speed to match the system requirements only as needed." – Alex Harvey, Director of AC and DC Drives, Control Techniques – Americas

Advanced VFDs take this a step further by coordinating multiple pumps through Multiplex control, which stages and destages units based on demand. Features like "sleep mode" cut energy use during idle periods, while "flying start" capabilities allow the VFD to safely regain control of a motor that’s already spinning – whether forward or backward due to back pressure. They also address challenges like cavitation by automatically slowing the pump when supply tank levels or net positive suction head available (NPSHa) are too low.

VFD Setup and Integration Best Practices

Getting the configuration of a Variable Frequency Drive (VFD) right is essential for achieving energy efficiency without unnecessarily complicating your system. The key lies in aligning the drive’s capabilities with the specific needs of your pump application and process.

Configuring VFDs for Pump Applications

The first step is to determine how the VFD should respond to your system’s process variables. Instead of setting a constant speed, configure the VFD to adjust based on factors like pressure, flow, temperature, or tank level. This type of variable speed control can lead to energy savings of up to 60%.

Pay close attention to speed range limits – usually in a 5:1 or 2:1 ratio – to keep the motor within its thermal tolerance and prevent overheating at lower speeds. Fine-tune the volts-to-hertz (V/Hz) ratio to match your application. For single-motor setups, dynamic V/Hz control works well, while multi-motor variable torque loads benefit from a square law characteristic mode. To reduce mechanical wear, enable S-ramp functions, which ensure smooth acceleration and deceleration.

"S-ramp acceleration and deceleration functions… provide the least amount of mechanical shock loading on the pump, motor and system." – Alex Harvey, Control Techniques – Americas

Activate additional features like flying start, which allows the VFD to safely control motors already spinning due to back pressure, and sleep mode, which shuts down pumps during zero-demand periods. Use skip frequencies to avoid operating speeds that may trigger system resonance and excessive vibration. Adjust the carrier frequency – commonly between 3 kHz and 18 kHz – to reduce audible noise, keeping in mind that higher frequencies may limit the allowable cable length between the VFD and motor. Lastly, ensure control valves are fully open or removed, allowing the VFD to regulate flow solely by adjusting motor speed.

For systems involving multiple pumps, further strategies can optimize efficiency.

Duty-Assist and Lead-Lag Configurations

In multi-pump systems, staging and destaging can significantly boost efficiency. VFDs can automatically start or stop additional pumps based on process variables like flow or pressure, ensuring extra pumps operate only when demand exceeds the capacity of a single unit.

"VFDs capable of responding to a process variable like pressure and staging and destaging additional pumps only when needed can provide a highly responsive system that ensures multiple pumps are operating only when needed, saving energy and resulting in greater efficiency and reliability." – Rebekah Macko, Geiger Pump & Equipment

For periods of low demand, consider using a small jockey pump equipped with its own VFD. This approach is more efficient than running a large pump at reduced speeds. Advanced VFDs often include multiplex control modules, which coordinate multiple pumps without needing an external PLC. Features like a redundant floating master ensure uninterrupted operation by automatically transferring control to another VFD if the lead drive fails.

Take advantage of the VFD’s built-in PID loops for automatic pressure or flow control, enabling seamless lead-lag transitions. Rotating the lead pump role among the units helps distribute wear evenly, keeping each pump closer to its Best Efficiency Point (BEP). This not only improves energy efficiency but also enhances mechanical stability by avoiding the inefficiencies of running multiple pumps in parallel at low loads.

sbb-itb-325a090

Maintenance and Monitoring of VFD Systems

Keeping Variable Frequency Drive (VFD) systems in top shape requires consistent maintenance and active monitoring. These efforts not only ensure the system runs smoothly but also safeguard the energy savings achieved through VFD integration, helping to avoid costly downtime.

Preventive Maintenance for VFDs

To maintain optimal performance, ensure the operating environment stays within 32°F and 104°F (0°C–40°C) and use the correct enclosure rating (NEMA 1, 12, or 3R) to shield the VFD from dust and moisture.

Regular inspections are key. Check all electrical connections, confirm proper grounding, and look for any cable wear or looseness. Keep motor lead lengths short to maintain performance and minimize underground cable lengths for added protection.

Install line reactors to reduce harmonic distortion and perform harmonic calculations during setup and maintenance. When sizing your VFD, focus on the motor’s specific amp rating rather than just horsepower – this is especially crucial for motors with six poles or more.

Make use of VFD fault codes to catch issues early and conduct hardware assessments routinely. Also, monitor the pump’s operation to ensure it stays near its Best Efficiency Point. Operating too far from this point can lead to increased wear and reduced efficiency.

Lastly, consider using digital monitoring tools to supplement routine checks for even better performance management.

Using Data Analytics for Performance Improvements

Modern VFDs go beyond basic maintenance by offering advanced analytics to optimize system performance. Many come equipped with built-in power meters and cost calculators that provide real-time energy savings data – eliminating the need for extra monitoring hardware. By using serial communication interfaces and expandable I/O, you can integrate this data into automation networks for centralized reporting and smarter decision-making.

Tracking flow rate over time and comparing it to your pump curve can reveal if a pump is worn, oversized, or losing efficiency. Monitoring vibration patterns can help identify system resonances; once identified, you can program skip frequencies to prevent the VFD from operating at problematic speeds. Additionally, setting up supply dip ride-through functions ensures the system remains operational during brief power losses without tripping.

To take it a step further, establish energy management metrics and consider adding extra monitoring equipment to keep an eye on system health. This data-driven approach allows you to identify trends, anticipate maintenance needs, and improve performance continuously, rather than simply reacting to problems when they arise.

Common Challenges and Solutions in VFD Applications

Variable Frequency Drives (VFDs) can offer impressive energy savings, but they also come with operational challenges that need careful handling to ensure system reliability and protect your equipment.

Avoiding Low-Speed Operation Problems

Operating motors at low speeds can lead to overheating and mechanical resonance. At reduced speeds, the cooling fans mounted on motor shafts lose their effectiveness, which can cause the motor to overheat. Most motors are designed with a speed ratio of 5:1 or 2:1, meaning they can safely operate at only 20% or 50% of their full speed.

"The motor should be suitably rated for the desired speed range or its thermal rating may be compromised." – Alex Harvey, Director of AC and DC Drives, Control Techniques – Americas

Mechanical resonance is another concern. If the pump speed matches the natural frequency of the piping system, it can result in excessive vibration and noise. To counter this, program the VFD to skip specific frequencies that cause resonance. Additionally, using S-ramp acceleration functions can help by reducing mechanical shock during speed changes, which protects components like pump impellers, motor bearings, and pipe joints.

For systems that often experience low-demand periods, consider adding a sleep function to shut down the pump instead of running it at unsafe low speeds. Another option is to use a smaller, VFD-controlled jockey pump, which handles minimal flow more efficiently than a large pump operating at low speed.

While low-speed challenges are common, VFDs can also introduce electrical issues that require attention.

Managing Harmonic Distortion and Electrical Noise

The process of converting AC power to DC and back to AC in VFDs generates harmonic currents – usually the 5th, 7th, 11th, and 13th harmonics. Standard six-pulse VFDs can cause total harmonic current distortion (THDi) levels between 50% and 70%, which can lead to overheating in transformers and cables and disrupt sensitive electronics like PLCs and distributed control systems.

To address this, installing line reactors at the VFD input can help stabilize current fluctuations, reducing harmonic content from over 60% to around 40%. For more demanding setups, a 12-pulse configuration can bring harmonics down to below 15%, while active harmonic filters can reduce THDi to less than 5%.

Cable length is another factor to consider. Long motor lead runs, especially in underground installations, may require lower carrier switching frequencies (around 3 kHz). While higher switching frequencies (up to 18 kHz) can reduce motor noise, they may also create voltage spikes that damage insulation over long distances. To minimize electrical noise, always ensure dedicated ground wires connect the motor to the VFD and the power source to the VFD.

Conclusion and Key Takeaways

Let’s wrap things up by highlighting the main advantages and practical steps for integrating Variable Frequency Drives (VFDs) into centrifugal pump systems.

VFDs are a smart investment when it comes to cutting energy costs. By leveraging the Affinity Laws, they can reduce power consumption and slash energy expenses by up to 60% – a game-changer for energy-intensive operations.

Key Benefits of VFDs for Energy Optimization

Here’s a quick recap of why VFDs are such a valuable addition to your system. Beyond saving energy, they also protect your equipment. By smoothing out hard-start shocks and minimizing vibrations, VFDs help extend the lifespan of your pumps, especially when they’re operating at their Best Efficiency Point.

Consider this: energy costs make up 95% of a motor’s total life cycle cost, while the initial purchase accounts for just 2% – a single month of electricity can cost as much as the motor itself. On top of that, VFDs maintain an impressive power factor of 0.97–0.98, ensuring efficient energy use.

"When a drive is applied to a fan or pump, the return on investment can be realized in as few as three to four months." – Tom Neuberger, Product Manager, Eaton

Steps to Implement VFDs Successfully

To get the most out of your VFD, start with a thorough pump system assessment to pinpoint the ideal operating conditions. Match the VFD to your motor’s speed range and thermal rating – most motors can safely handle speed ratios of 5:1 or 2:1. Fully open control valves so the VFD can manage flow directly, avoiding wasted energy from throttling.

For systems with multiple pumps, use staging and destaging to ensure pumps only run when needed. Don’t forget to configure skip frequencies to avoid resonance issues, install line reactors to control harmonics, and keep motor lead lengths short to protect insulation.

Need expert guidance for specialized pumping systems or oilfield equipment? Check out NOVA Petroleum Services for support.

FAQs

How do variable frequency drives (VFDs) enhance energy efficiency in industrial motor systems?

Variable frequency drives (VFDs) are a smart way to boost energy efficiency by adjusting a motor’s speed to meet the exact demands of a process. Instead of running at full speed and using throttling devices to control flow or pressure, VFDs allow motors to operate only as fast as necessary. This approach minimizes energy waste and keeps the system running more efficiently.

Thanks to the affinity laws, the energy savings can be dramatic. Power consumption decreases roughly with the cube of the motor’s speed, so even a slight reduction in speed can lead to noticeable savings. On top of that, VFDs help reduce mechanical stress on equipment, which can extend its lifespan. This makes them a practical and cost-saving choice for improving energy use in industrial settings.

What are the main benefits of using VFDs in centrifugal pump systems?

Variable-frequency drives (VFDs) give centrifugal pumps the ability to run at exactly the speed needed, which brings some major benefits. One of the biggest perks? Energy savings. Because pump power consumption drops dramatically with even small speed reductions – following the cube of the speed – adjusting the speed can make a huge difference. For instance, if a pump runs at 80% of its full speed, it uses nearly half the energy. Drop that speed to 50%, and power consumption plummets to just about 12% of what it would be at full speed. These savings don’t just lower energy use; they also cut operating costs, often paying for the initial investment in just a few months.

Beyond energy efficiency, VFDs help protect the pump’s components. By allowing for smooth starts and stops, they reduce mechanical stress on motors, bearings, and seals, which can significantly extend the pump’s lifespan. On top of that, VFDs improve process control by enabling precise adjustments to speed, pressure, and flow. This not only boosts reliability but also reduces the need for frequent maintenance.

For operators in the U.S., NOVA Petroleum Services offers top-notch VFDs and pump system solutions. Their products are designed to help businesses capture these benefits while staying compliant with local standards and operational needs.

How do VFDs help increase the lifespan of industrial equipment?

Variable Frequency Drives (VFDs) help industrial equipment last longer by promoting smoother operation. They allow motors to soft-start and soft-stop, which cuts down on mechanical stress and reduces wear and tear on components. By fine-tuning motor speed to align with process needs, VFDs also lower inrush currents, preventing unnecessary strain on the system.

This careful control improves reliability and trims down maintenance requirements, leading to time and cost savings over the long haul. With reduced stress on your machinery, you’ll see better performance and an extended service life for your equipment.