Centrifugal pumps are essential in oilfield operations, but inefficiencies can lead to wasted energy, higher costs, and frequent breakdowns. By improving pump efficiency, you can save thousands annually and extend equipment lifespan. Here’s what you need to know:

- Energy Savings: A 3% efficiency increase can save $8,393 per year on electricity.

- Best Efficiency Point (BEP): Operating near BEP reduces wear and maximizes performance.

- Sizing & Selection: Properly sized pumps avoid energy waste and costly maintenance.

- Maintenance Matters: Routine checks and condition monitoring prevent failures.

- Temperature & Viscosity: Managing these factors ensures smoother operations.

Efficiency isn’t just about cutting costs – it’s about maintaining reliability and reducing downtime. Read on to learn actionable strategies for better pump performance.

Systems Approach in Selecting and Sizing the Centrifugal Pumps

Operating at the Best Efficiency Point (BEP)

Centrifugal Pump Performance: Operating Conditions Impact on Efficiency and Reliability

What is BEP and Why It Matters

The Best Efficiency Point (BEP) represents the flow rate at which a centrifugal pump operates most efficiently, minimizing energy loss during operation. At this flow rate, only a small amount of fluid is diverted back to the suction side, ensuring optimal performance.

"At the BEP, the least amount of fluid is bypassed back to the low-pressure (or suction) side. The pump runs the smoothest at this point, the flow is the cleanest moving through the pump, and there is minimal radial (or side) loading on the pump bearings."

– Dan Csomos, National Sales Manager, Ruthman Companies

Staying close to BEP is crucial for extending the lifespan of equipment, especially in demanding oilfield environments. Straying from this point increases internal pressure differences, causing the impeller and shaft to deflect, which can damage seals and bearings. Given that centrifugal pumps account for over 90% of pumps in the oil and gas sector, operating near BEP is key to reducing energy waste and lowering maintenance expenses.

To maintain reliability, pumps should ideally operate between 50% and 120% of BEP. For best results, size pumps to run at approximately 85% of BEP. This allows for up to 35% system fluctuations without compromising performance or durability.

Next, let’s explore how to identify when your pump is moving away from its BEP.

Warning Signs of Operating Away from BEP

When a pump operates outside its BEP, efficiency drops, and wear on components increases. Fortunately, pumps often provide clear warning signs when this happens. Excessive vibration is one of the most noticeable indicators, caused by internal turbulence at low flow or cavitation at high flow rates. Strange noises, such as a gravelly sound from cavitation or a rumbling from reverse flow, are also red flags.

Temperature increases are another telltale sign. Operating below 60% of BEP wastes energy as heat, which can damage seals and even lead to fluid vaporization. Frequent seal or bearing failures, often due to increased vibration and shaft deflection, are common in oilfield applications when pumps stray from BEP. Other signs include unexpected spikes in power consumption and the presence of thermal hotspots in bearings or seals.

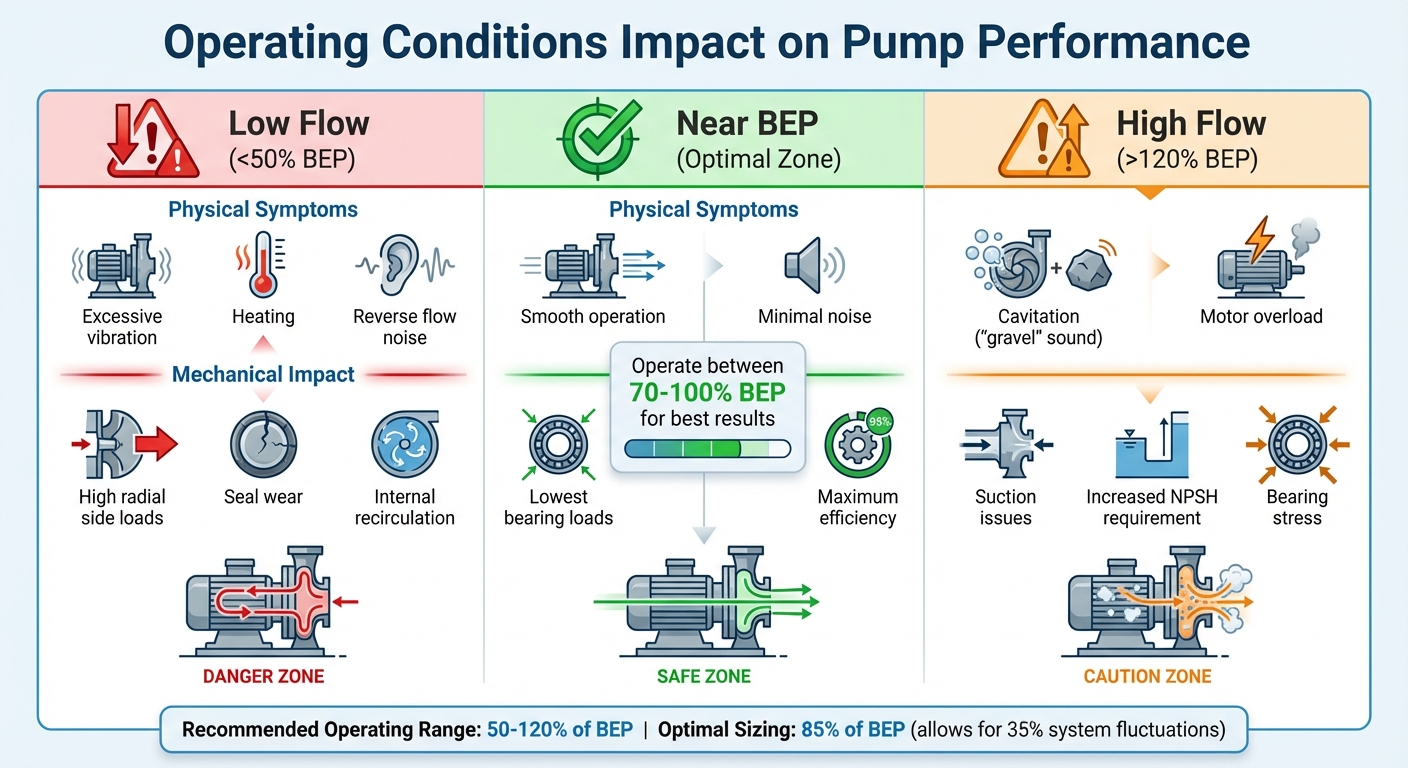

The table below highlights how operating conditions impact pump performance and reliability:

| Operating Condition | Physical Symptoms | Mechanical Impact |

|---|---|---|

| Low Flow (<50% BEP) | Excessive vibration, heating, reverse flow noise | High radial side loads, seal wear, internal recirculation |

| Near BEP | Smooth operation, minimal noise | Lowest bearing loads, maximum efficiency |

| High Flow (>120% BEP) | Cavitation ("gravel" sound), motor overload | Suction issues, increased NPSH requirement, bearing stress |

Pump Selection and Sizing

Matching Pump Specifications to Your Needs

Choosing the right pump starts with gathering detailed operational documentation. This includes key documents like the Process Design Basis, P&ID, and Material Balance, which provide critical data such as flow rates, density, viscosity, and vapor pressure. These details are essential to avoid the pitfalls of undersizing, which can limit production, and oversizing, which wastes energy and accelerates wear.

For applications where temperatures fall below 5°F (-15°C) or exceed 266°F (130°C), it’s recommended to follow API 610 standards and opt for centerline-supported casings to handle thermal expansion effectively. Keep in mind that high-viscosity fluids reduce efficiency, so managing temperature is crucial to maintain adequate Net Positive Suction Head (NPSH) and prevent cavitation.

"Sizing the pump properly at the outset is critical. This is accomplished by advanced analytics, which place the best efficiency point (BEP) at or slightly below the rated point."

– Tom Helmreich, Global Product Line Director, Sundyne

Rotational speed presents a balancing act. While higher speeds can result in smaller, more efficient, and cost-effective pumps, they may also shorten the lifespan of seals and bearings. If NPSH margins are less than 1.5–2 meters, shop testing across at least eight operating points is advised to ensure reliability.

With these factors in mind, let’s explore common sizing mistakes and how to avoid them.

Common Sizing Mistakes to Avoid

Oversizing is a frequent issue, often caused by overly conservative estimates. This leads to energy waste and increased wear on components like valves, piping, bearings, and seals. It’s worth noting that maintenance and operations account for the majority of a pump’s life cycle costs.

Watch for these red flags of poor sizing: control valves that are heavily throttled, high bypass flow rates, excessive flow noise, and frequent bearing or seal failures. Undersizing, on the other hand, can compromise production goals and increase the risk of cavitation. Operating below a pump’s minimum continuous flow rate – typically around 60% of its BEP flow – can result in instability, temperature spikes, and cavitational damage.

Improper sizing also has a financial impact. Pump efficiency can drop by 10% to 25% before replacement becomes necessary, with degraded or poorly sized pumps often operating at efficiencies as low as 50–60%. Even small tweaks can yield big results – reducing pump speed by 20% can lower power consumption by about 50%. For oversized pumps already in use, consider trimming the impeller diameter or adding a Variable Frequency Drive (VFD) instead of replacing the entire pump.

When working with heated fluids, don’t overlook the higher pressure drops that can occur in two-phase discharge calculations. Factor in components like valves, strainers, and elbows early in the design process to ensure NPSH requirements are met.

System Design and Piping Optimization

Reducing Friction and Pressure Losses

The way you design a piping system has a direct impact on how efficiently your pump operates. Friction losses are a major factor, and they’re closely tied to pipe diameter. Larger pipes may cost more initially, but they significantly reduce friction, meaning your pump doesn’t have to work as hard to maintain pressure. Considering that over 90% of pumps in the oil and gas industry are centrifugal, this aspect is critical to operations.

Let’s start with suction piping. Keep it as short as possible, and make sure its size matches or exceeds the pump inlet size. If a size transition is needed, use eccentric reducers with the flat side on top (when the fluid is coming from below). This prevents air pockets from forming, which could otherwise disrupt the pump’s suction.

"Pumps should never support the suction or discharge piping. Any stress on the pump casing by the piping system greatly reduces pump life and performance."

– Jeff Simpson, Crane Engineering

Straight pipe runs are crucial. Include a straight section of pipe between the pump inlet and any obstructions (like valves, elbows, or tees). This section should be 5 to 10 times the pipe diameter to ensure a smooth, uniform flow. Without this, you risk "side loading" the impeller, which can lead to uneven bearing wear. If space is tight and you must place an elbow near the inlet, opt for a long-radius elbow to reduce flow disruption.

Another way to improve efficiency is by using Variable Frequency Drives (VFDs). These can cut energy use by up to 40% compared to throttling valves. Throttling creates unnecessary backpressure, forcing the pump to work harder. In systems where friction head dominates, lowering pump speed by 20% can reduce power consumption by about 50%.

Reducing friction is essential, but it’s just one piece of the puzzle. Ensuring proper suction conditions is equally important for long-term pump performance.

Maintaining Proper NPSH (Net Positive Suction Head)

Cavitation is the silent killer of pump efficiency and components. It happens when the Net Positive Suction Head Available (NPSHa) in your system drops below the pump’s required NPSH (NPSHr). When this occurs, vapor bubbles implode with pressures as high as 49 MPa and impact frequencies reaching 2,000 to 3,000 Hz. This can rapidly erode metal surfaces and damage seals and bearings.

To avoid cavitation, design suction lines to be short and streamlined, minimizing air entrapment and preserving NPSH. Keep supply tanks full and ensure all pipe connections are secure to prevent air intrusion and vortices. Be cautious with fluid temperature – while higher temperatures reduce viscosity, they also raise vapor pressure. This reduces the available NPSH, increasing the risk of cavitation.

For critical systems where the NPSH margin is less than 1.5 to 2 meters, shop testing at multiple operating points is essential to confirm reliability. You can also improve NPSHa by lowering the pump’s installation height or increasing the pressure at the liquid level in your supply tank. If you hear a "crackling" sound, it’s a clear sign of cavitation – and immediate action is needed to prevent further damage.

Maintenance and Monitoring Practices

Preventive Maintenance Schedules

Effective maintenance is the backbone of keeping pumps running smoothly and avoiding expensive downtime in oilfield operations. A well-organized schedule ensures efficiency and helps catch potential problems before they escalate.

Begin with daily visual inspections. Look for leaks around joints and seals, listen for any unusual noises like cavitation, and manually check bearing temperatures to spot early warning signs. On a weekly basis, use a thermal gun to measure bearing housing temperatures and clean the inlet strainers to maintain optimal flow.

Monthly, perform vibration analysis with a portable analyzer to compare current readings against baseline values. This can reveal early signs of bearing wear or misalignment, allowing you to address issues before they lead to a failure. For quarterly or annual maintenance, more detailed tasks are necessary: check pump-to-driver alignment, inspect wear rings for damage, and fully disassemble components like the impeller and casing to assess wear patterns.

"Proper lubrication minimizes friction and bolsters pump efficiency."

– PumpWorks

Mechanical seals require extra care. They are a common cause of unplanned shutdowns in major process pumps, with replacement costs ranging from $3,000 to $20,000 per incident. Pay close attention to seals during the first few hours after maintenance, as most installation-related issues occur within the initial day of operation. In oil refineries, following proper lubrication protocols can double bearing life from three years to six, significantly reducing outage expenses.

In addition to these scheduled tasks, leveraging condition monitoring technologies can provide real-time insights, enabling a more proactive approach to maintenance.

Condition Monitoring Technologies

Routine inspections are essential, but advanced monitoring tools now make it possible to track equipment performance in real time. Modern condition-based maintenance relies on sensors and remote monitoring systems to flag service needs only when performance starts to decline, extending the time between repairs and lowering costs.

Vibration sensors are useful for identifying shaft misalignment, bearing wear, and unbalanced loads, while temperature probes can detect overheating early on. Pressure and flow instruments continuously monitor suction and discharge pressure, as well as flow rates, helping to identify blockages, performance dips, or deviations from the Best Efficiency Point (BEP).

Here’s a quick breakdown of key monitoring tools and their benefits:

| Monitoring Technology | Primary Issue Detected | Benefit to Oilfield Operations |

|---|---|---|

| Vibration Sensors | Misalignment, Bearing Wear | Reduces unplanned downtime and shaft damage |

| Pressure Gauges | Cavitation, System Blockage | Protects impellers and ensures consistent flow |

| Temperature Probes | Overheating, Lubrication Failure | Prevents catastrophic failures in bearings and seals |

| Flow Meters | Efficiency Loss, Internal Wear | Enhances energy use and production output |

| Seal Leak Detectors | Seal Face Failure | Reduces hazardous leaks and environmental risks |

Adding acoustic monitoring can also help detect early signs of cavitation or component failure. Training operators to recognize and report unusual sounds provides a simple yet effective way to identify potential problems. When paired with Variable Frequency Drives (VFDs), sensor data can enable dynamic adjustments to flow rates, maintaining efficiency and reducing wear under changing operational conditions.

sbb-itb-325a090

Viscosity and Temperature Management

When it comes to maximizing pump performance, managing viscosity and temperature effectively plays a crucial role. These factors directly impact how efficiently a pump operates, particularly in systems handling fluids like crude oil.

How Fluid Viscosity Affects Efficiency

The viscosity of a fluid significantly influences the performance of centrifugal pumps. Higher viscosity increases internal friction, which reduces hydraulic efficiency and places more strain on the motor. This leads to three key issues: a drop in the total head produced, reduced flow capacity, and a noticeable decline in overall efficiency compared to standard water-based performance curves.

Take, for example, a study conducted by Dr. Mahmood Moshfeghian of John M. Campbell & Co. on a 100-mile, 16-inch crude oil pipeline. The findings showed that increasing the crude oil’s API gravity from 30 to 40° reduced power requirements by about 30%. Lighter crude oil (with a higher API gravity) has lower viscosity, making it easier to pump. Additionally, seasonal temperature changes, ranging from 70°F to 100°F, caused pumping power requirements to fluctuate by over 8% after accounting for viscosity adjustments.

"The reduction of viscosity results in higher a Reynolds number, lower friction factor and in effect lowers pumping power requirements."

– Dr. Mahmood Moshfeghian, John M. Campbell & Co.

For crude oil systems, applying a viscosity correction factor between 0.95 and 0.98 ensures more accurate pump efficiency calculations. Relying on a fixed efficiency rating (like 0.75) across all fluids can lead to substantial errors in power estimates. Instead, use standards from the Hydraulic Institute (HI) or models like Stepanoff or Paciga to adjust water-based pump curves for the specific viscosity of the fluid being handled.

While viscosity adjustments are essential, combining them with proper temperature management can further improve pump efficiency.

Temperature Control Methods

Temperature and viscosity go hand in hand. As temperatures rise, crude oil viscosity decreases, leading to better flow characteristics and reduced friction within the system. However, extreme temperatures – whether below 5°F or above 266°F – demand pumps designed to handle thermal stress, such as those built to API 610 standards.

For applications involving high temperatures (above 266°F), centerline-supported pump casings are critical. This design helps maintain alignment and stability as the pump expands and contracts due to temperature changes, minimizing thermal expansion’s impact on piping loads. Compared to traditional foot-mounted designs, a centerline-supported, top-discharge configuration offers superior stability under thermal stress.

"Pump casings should be centerline supported to reduce the effects of temperature differences."

– Amin Almasi, Principal Machinery Consultant

Seasonal temperature shifts also require attention, especially in pipeline operations. Colder ambient temperatures can increase fluid viscosity, leading to unexpected spikes in power demand. To address this, integrate temperature probes with variable frequency drives (VFDs) to adjust pump speed dynamically as fluid properties change. This approach ensures the pump operates near its Best Efficiency Point, even when temperatures fluctuate throughout the year. By fine-tuning these parameters, energy consumption is reduced, and wear on the pump is minimized.

Mechanical Seal Best Practices

Mechanical seals play a crucial role in keeping pumps efficient and minimizing downtime. With replacement costs ranging from $3,000 to $20,000, maintaining these seals is one of the most expensive aspects of pump operation. Proper selection and care of mechanical seals not only extend their lifespan but also help cut operational costs.

Selecting the Right Seal Material

Choosing the right seal material depends heavily on your operating conditions. Fluid compatibility is critical – seal materials must withstand exposure to the chemicals and hydrocarbons commonly found in oilfield fluids. For extreme temperatures, whether below 5°F or above 266°F, seals must meet API 610 standards to handle the challenge.

Modern soft-mount designs are particularly effective in managing temperature and pressure changes. These designs improve the flatness of sealing surfaces, which helps maintain the thin lubricating film between seal faces. Cartridge-type mechanical seals are often the go-to choice for oilfield applications because they’re easy to install and highly reliable.

"Upgrading these elements [seals and bearings] can double the service life of the bearings and seals at a fraction of the cost of replacing the entire pump."

– Tom Helmreich, Global Product Line Director, Sundyne

Pump speed is another critical factor when selecting seal materials. Higher rotational speeds shorten seal life, so materials must align with your pump’s operating speed. If cavitation is a concern, opt for materials with high strength and toughness to withstand the mechanical damage caused by vapor bubble implosions. These implosions can create partial pressures reaching hundreds of atmospheres. Once the right material is in place, consistent maintenance becomes essential for long-term performance.

Seal Maintenance and Replacement

During the initial hours of operation, closely monitor seals. Persistent leakage often points to improper installation or a mismatch in selection. Installing dry-run monitors with alarms is a smart move – these sensors alert operators when lubrication levels drop too low to protect the seal faces, helping to prevent catastrophic failures.

Keeping pumps running near their Best Efficiency Point (BEP) is another key to seal longevity. Operating outside the 70% to 100% BEP range increases vibrations from cavitation and recirculation, which can damage fragile seal components. Modifying seal housings to eliminate high-point vapor pockets improves fluid flow and extends the life of the seals. Additionally, machining shaft sleeves to extremely tight tolerances ensures the parallelism and flatness needed for optimal performance.

While mechanical seals can last between one and three years under ideal conditions, poor selection or operational issues can lead to failures in just a few months. Regular inspections and timely replacements are crucial to avoiding heat buildup and face cracking, which can result in catastrophic failures. Considering that maintenance and operational costs can make up as much as 80% of a pump’s total life cycle expenses, investing in high-quality seals and adhering to proper maintenance practices offers significant savings over time.

High-Quality Pumping Systems from NOVA Petroleum Services

Efficiency is the backbone of oilfield operations, and high-performing pumping systems are a critical part of the equation.

Pumping Solutions Available

NOVA Petroleum Services offers a range of centrifugal pumps built to handle the demanding conditions of oilfield environments. Among their offerings:

- The Mission Magnum I: A slurry pump capable of handling up to 3,400 gallons per minute, with pressure heads reaching 550 feet.

- The Mission 2500 Supreme: Designed for abrasive fluids, it features a replaceable casing wear pad, semi-open impeller, and labyrinth seals to shield bearings from contamination.

- The Mission Magnum XP: Engineered for high-volume applications involving abrasive and corrosive materials.

These pumps are sourced from leading manufacturers across the USA, Canada, the UK, and the EU. What sets NOVA apart is their ability to tailor pump specifications to exact hydraulic needs. This eliminates inefficiencies caused by over- or under-sizing while ensuring customers receive reliable, industry-standard technology.

Beyond supplying durable pumping systems, NOVA Petroleum Services offers solutions to keep equipment running smoothly for longer, including strategic upgrades to enhance performance and extend service life.

Support for Equipment Upgrades and Replacements

To help operators get the most out of their equipment, NOVA Petroleum Services provides modular upgrades that can significantly extend pump life. Replacing components like process seals, bearings, seal housings, and shaft sleeves can double the lifespan of a pump – at a fraction of the cost of purchasing new equipment.

As oilfield conditions shift, pump re-rating ensures that existing equipment continues to operate efficiently. NOVA’s technical support team works closely with operators to adapt pumps to new flow and pressure requirements, avoiding costly replacements. This approach helps maintain pumps near their Best Efficiency Point, lowering operational costs and delivering maximum value over time.

Conclusion

Boosting centrifugal pump efficiency is essential for maintaining reliability and cutting down on costly downtime, which directly impacts profitability. Industry data reveals that average pumping efficiency in many operations lags at under 40%. Additionally, maintenance expenses can make up as much as 80% of a pump’s total life cycle costs. These statistics highlight the untapped potential for improvement when operators prioritize best practices.

To enhance performance, focus on operating pumps near their Best Efficiency Point (BEP), selecting appropriately sized equipment, and integrating Variable Frequency Drives (VFDs). As Robert Lax from ITT PRO Services explains, excess mechanical energy manifests as vibration, heat, and noise, which can compromise system reliability. Thoughtful system design and consistent monitoring help eliminate these inefficiencies, avoiding the expensive failures often linked to oversized or neglected systems.

Investing in strategic upgrades, such as replacing seals, bearings, or shaft sleeves, can significantly extend a pump’s lifespan without the high costs of full replacements. For instance, mechanical seal replacements alone can range from $3,000 to $20,000 per instance, making preventive maintenance a cost-effective choice.

Oilfield operators also gain a competitive edge with NOVA Petroleum Services, which provides high-quality pumps and expert support. Their offerings include pumps designed for tough conditions, along with specialized expertise in system re-rating and component upgrades to keep equipment performing at its best.

FAQs

Why is operating near the Best Efficiency Point (BEP) important for extending a centrifugal pump’s lifespan?

Operating a centrifugal pump near its Best Efficiency Point (BEP) helps keep it running within its ideal hydraulic range. This approach minimizes problems like excessive vibration, cavitation, and stress on bearings – issues that often lead to wear and tear. By cutting down on these stresses, the pump operates with less strain, extending its lifespan and boosting reliability.

Operating close to the BEP also improves energy efficiency, which can significantly lower operational costs while ensuring steady performance. This is especially important in oilfield operations, where durable and efficient pumps are key to reducing downtime and maintaining productivity.

How can you tell if a centrifugal pump is not operating at its Best Efficiency Point (BEP)?

When a centrifugal pump operates outside its Best Efficiency Point (BEP), it tends to show some clear warning signs. You might notice a drop in flow or pressure that doesn’t match the pump’s performance curve, often paired with a spike in power usage.

Other red flags include excessive vibration, strange noises, overheating, cavitation, or seal wear. These problems can stem from issues like partially closed suction or discharge valves, clogged piping or strainers, or vapor mixed into the fluid. Tackling these issues quickly is key to keeping the pump running efficiently and prolonging its service life.

How does fluid viscosity impact the efficiency of centrifugal pumps in oilfield operations?

Fluid viscosity is a key factor that directly impacts the performance of centrifugal pumps in oilfield operations. When viscosity increases, it creates more resistance inside the pump. This added resistance leads to lower flow rates and reduced head while demanding more brake horsepower to keep the pump running. The end result? A clear drop in the pump’s overall efficiency.

Addressing these challenges starts with choosing pumps specifically designed for the viscosity of the fluid being moved. Regular maintenance and consistent performance checks are also crucial steps to keep these pumps running efficiently, even in the tough conditions often found in oilfield environments.