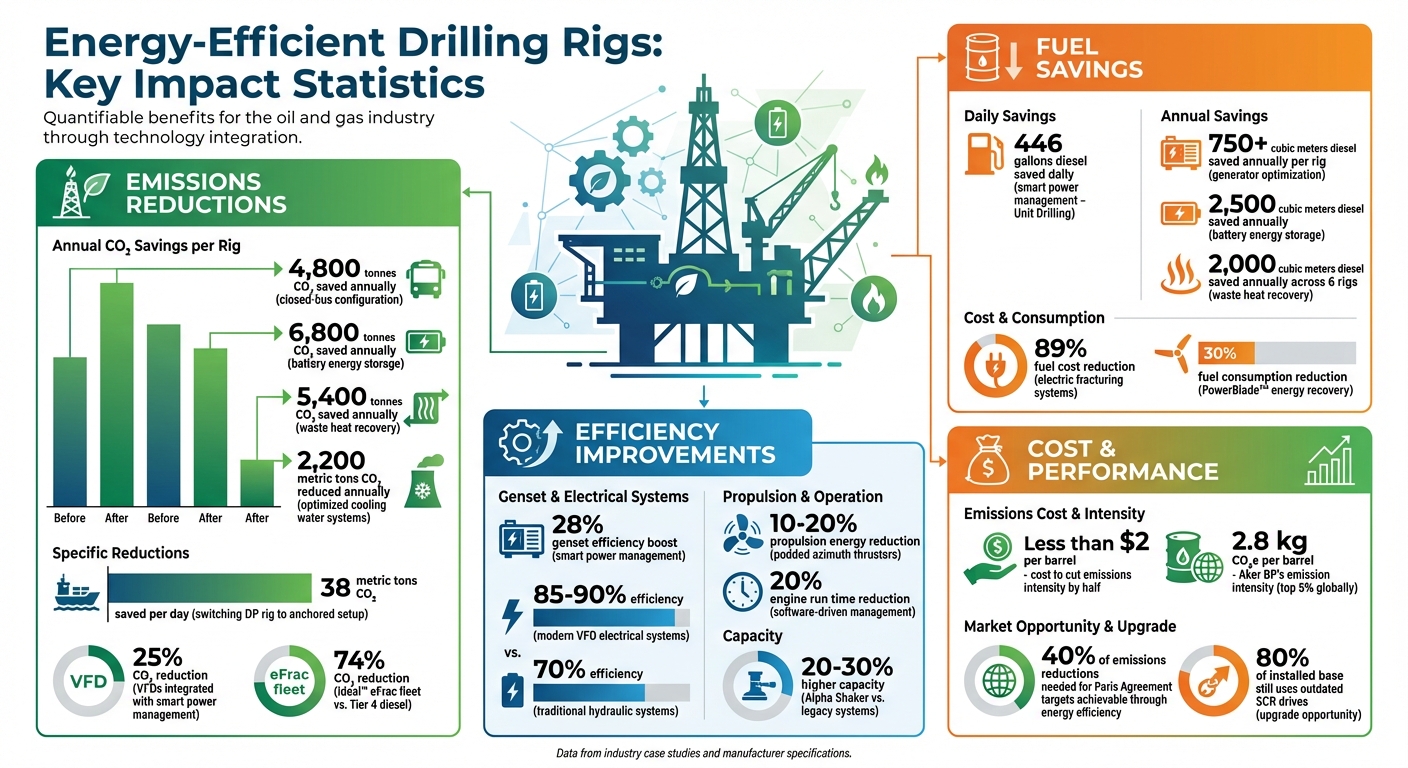

Energy-efficient rigs are transforming the oil and gas industry by reducing emissions and fuel consumption without sacrificing performance. Here’s how:

- Diesel Use Reduction: Advanced power management systems, like closed-bus configurations and automation, cut fuel waste and lower CO₂ emissions by thousands of tons annually.

- Modern Equipment: Variable Frequency Drives (VFDs) and electrification improve efficiency, replacing outdated hydraulic systems and reducing energy losses.

- Waste Heat Recovery: Capturing heat from exhaust and cooling systems saves fuel and reduces emissions.

- Digital Monitoring: Tools like Smart Equipment Analytics provide real-time data to optimize operations and identify inefficiencies.

- Compliance: These rigs meet stringent global standards while keeping production costs low – adding less than $2 per barrel.

Energy-efficient rigs are a practical solution for meeting emissions targets, improving operational performance, and keeping costs manageable. Companies like NOVA Petroleum Services offer retrofit options and new systems that make upgrading easier and faster for operators.

Energy-Efficient Drilling Rigs: Emissions Reduction and Fuel Savings Statistics

Environmental Problems with Conventional Drilling Rigs

Fuel Consumption and Greenhouse Gas Emissions

Most conventional drilling rigs rely heavily on diesel-powered internal combustion engines, especially in offshore operations and mobile onshore setups where grid connections aren’t available. This dependence on diesel contributes to significant emissions of CO₂, nitrogen oxides (NOₓ), sulfur oxides (SOₓ), and volatile organic compounds (VOCs) into the atmosphere. Dynamically positioned (DP) rigs, in particular, consume about 40% more diesel than anchored rigs because their engines must run continuously to maintain position. For example, switching a single DP rig to an anchored setup during calm summer conditions can save around 38 metric tons of CO₂ emissions per day.

Inefficient Operations

Conventional rigs also suffer from energy inefficiencies that exacerbate their environmental impact. Poor power management is a major issue, with many offshore rigs operating in "open-bus" configurations. This setup involves multiple diesel generators running simultaneously at low or idle loads, rather than adjusting output based on actual demand. Operators often avoid shutting down unnecessary engines due to safety concerns, leading to wasted energy.

These rigs also operate in isolated "silos", requiring additional capacity to prevent blackouts, which further increases fuel consumption and emissions. On top of that, traditional rigs lose significant energy through outdated heating systems. Instead of using waste heat from engine exhaust or cooling water, they rely on energy-intensive steam or thermal oil boilers. Additionally, older hydraulic equipment on these rigs operates at about 70% efficiency, while modern electrical systems achieve efficiency levels between 85% and 90%.

Regulatory Pressures

The inefficiencies of conventional rigs make it even harder to comply with strict environmental regulations. For example, the limited physical space on traditional land rigs makes it nearly impossible to install the bulky Selective Catalytic Reduction (SCR) systems and large Diesel Exhaust Fluid (DEF) storage tanks required for modern emissions control. DEF itself presents logistical challenges, as it freezes at 12°F and degrades above 90°F, complicating transport and storage at remote sites. As Caterpillar explains:

The size and arrangement of the aftertreatment, DEF storage tanks, DEF pumping units and associated piping are prohibitive on a land drilling rig.

Many older rigs still use Tier 2 engines, which lack the high-pressure fuel injection and exhaust gas recirculation systems necessary to meet Tier 4 Final standards. Current regulations also mandate the use of Ultra Low Sulfur Diesel, which has a maximum sulfur concentration of just 15 parts per million – a 99% reduction from earlier levels. Since conventional rigs were not designed with these stringent requirements in mind, they often struggle to meet modern standards without extensive and costly upgrades.

Technologies That Make Rigs More Energy-Efficient

Improved Power Management Systems

Modern rigs are leveraging advanced power management techniques to operate more efficiently. One key approach is the use of closed-bus systems, which allow fewer engines to run at optimal loads, reducing fuel waste. Another method, peak shaving, employs energy storage to smooth out sudden spikes in demand, ensuring generators work more effectively. Software like Load-Dependent Start-Stop (LDSS) automates generator output adjustments to match real-time energy needs, eliminating the need for manual intervention. For example, in July 2021, Unit Drilling implemented smart power management, which boosted genset efficiency by 28% and saved 446 gallons of diesel daily. Additionally, optimizing cooling water systems and generator management software has been shown to cut diesel consumption by over 750 cubic meters and reduce CO₂ emissions by nearly 2,200 metric tons per rig annually. Enhanced motor drives further build on these advancements, driving down energy use even more.

Variable Frequency Drives (VFDs) and Pump Improvements

Variable Frequency Drives (VFDs) are transforming energy efficiency on rigs by providing precise control over speed and torque for critical equipment like mud pumps, drawworks, and rotary tables. These drives replace less efficient hydraulic systems with VFD-controlled motors, improving efficiency from 70% to 85–90%. This shift not only reduces fuel consumption and emissions but also eliminates risks associated with hydraulic fluid leaks and lowers maintenance costs by reducing mechanical wear. Additionally, podded azimuth thruster systems, powered by variable-speed electric motors, can cut propulsion energy needs by 10–20% compared to traditional mechanical systems. When integrated with smart power management systems, VFDs can contribute to a CO₂ emissions reduction of up to 25%.

Smart Monitoring and Automation

Digital tools are playing a critical role in making rigs more energy-efficient. Platforms like Power BI provide real-time tracking of emissions and fuel efficiency, giving operators the data they need to make informed decisions. Smart Equipment Analytics (SEA) continuously monitors rig systems, identifying inefficiencies before they become costly problems. A notable example of automation’s impact is Nabors Industries’ retrofit of a land rig (X29) in November 2022. Using the Red Zone Robotics (RZR) Rig Floor Module, the company introduced hands-free pipe handling and autonomous task management, achieving newbuild-level performance at a fraction of the cost. Anthony Petrello, Chairman, President, and CEO of Nabors, highlighted this breakthrough:

R801 proved fully automated land drilling is possible. Now RZR has demonstrated those same levels of automation can be scaled across existing assets at a fraction of the cost of a newbuild.

Baker Hughes has also embraced digital efficiency, completing 560 lifecycle assessments in 2024 with its FastLCA tool. These assessments quantified avoided and removed greenhouse gas emissions, contributing to a 29.3% reduction in Scope 1 and 2 emissions compared to 2019 levels. Additionally, software-driven engine management systems extend engine life by reducing run time by 20%, further enhancing operational efficiency. These digital innovations, combined with advanced power and drive systems, create a unified strategy for building energy-efficient rigs.

How Energy-Efficient Rigs Meet Environmental Standards

Reducing Scope 1 Emissions

Scope 1 emissions refer to the direct greenhouse gases released from sources a company owns or controls – mainly from burning diesel in rig engines and generators. Energy-efficient rigs tackle these emissions through electrification, improved efficiency, and carbon removal technologies.

Modern upgrades significantly cut diesel consumption. Switching to a closed-bus configuration, for instance, can reduce annual CO₂ emissions by 4,800 tons and cut engine hours by 20%. Additional measures like battery energy storage and waste heat recovery further reduce diesel use, saving 2,500 cubic meters of fuel annually and lowering emissions by 6,800 and 5,400 tons, respectively.

Aker BP provides a strong example of these technologies in action. By electrifying fields such as Johan Sverdrup, Edvard Grieg, and Ivar Aasen with power sourced from shore, the company achieved a greenhouse gas emission intensity of just 2.8 kg CO₂e per barrel of oil equivalent in 2024. This places Aker BP among the top 5% of low-emission producers worldwide. These advancements show that energy-efficient rigs not only align with corporate sustainability goals but also maintain operational excellence.

Beyond reducing direct emissions, these efforts help companies meet stringent regulatory requirements.

Compliance with Global Standards

Energy-efficient rigs play a key role in meeting international energy management standards like ISO 50001 by setting clear energy efficiency goals. These systems help operators optimize processes and demonstrate adherence to global frameworks. In fact, energy efficiency measures account for over 40% of the emissions reductions needed to align with the Paris Agreement‘s targets.

The DNV ABATE Class notation offers a structured certification framework for mobile offshore units to validate their greenhouse gas reduction efforts. This system provides operators with a clear method to document their emissions-cutting initiatives, ensuring transparency for regulators and stakeholders alike.

The International Energy Agency emphasizes the importance of energy efficiency in achieving climate goals:

Energy efficiency could deliver a reduction in annual energy-related emissions of 3.5 Gt CO₂-eq (12%) compared with 2017 levels, delivering over 40% of the abatement required to be in line with the Paris Agreement.

For drilling operations, these measures are not only effective but also cost-efficient. Cutting emissions intensity by half costs less than $2 per barrel of oil equivalent, proving that environmental responsibility and financial practicality can go hand in hand.

sbb-itb-325a090

NOVA Petroleum Services: Solutions for Energy-Efficient Drilling

Equipment Solutions

NOVA Petroleum Services offers cutting-edge oilfield technologies designed to make drilling more energy-efficient. Their lineup includes electric-driven fracturing systems, energy recovery technologies, and automated drilling platforms – all aimed at reducing fuel use and emissions without compromising performance.

One standout is the Ideal™ eFrac fleet, which replaces traditional diesel power with 5,000-hp electric pumps featuring simplified drive trains. This shift can lower fuel costs by up to 89% and cut CO₂ emissions by as much as 74% compared to Tier 4 diesel fleets. Travis Bolt, Product Development Manager at NOV, highlights the system’s eco-friendly benefits:

The Ideal eFrac system makes an environmental impact through cleaner, more efficient equipment that still performs to expectations.

Another innovative solution is the PowerBlade™ energy recovery system, which captures electrical braking energy from equipment like drawworks, cranes, and winches. Instead of wasting this energy, it’s stored in flywheels or batteries and fed back into the power grid, reducing fuel consumption by up to 30%. For hydraulic systems, the EcoBooster™ stabilizes ringline pressure and enables peak shaving on the Hydraulic Power Unit, further improving efficiency.

NOVA’s NOVOS™ reflexive automated drilling system takes optimization to the next level by using intelligent monitoring and automation to streamline drilling processes. This reduces both the energy and time needed to complete a well. For solids control, the Alpha Shaker processes cuttings at 20% to 30% higher capacity than other single-deck high-performance shakers, while also producing drier cuttings. Brad Wood, Senior Vice President of Technology at NOV, explains:

The Alpha Shaker produces considerably drier cuttings compared to legacy shaker systems. Drier cuttings translate to lower waste volumes and fewer waste haul trips.

These technologies not only cut fuel consumption but also provide straightforward options for retrofitting and upgrading existing equipment.

Support for Equipment Renewal and Upgrades

NOVA Petroleum Services makes it easier for operators to upgrade their equipment for faster efficiency improvements. Retrofitting older systems often achieves emissions reductions more quickly than waiting for new rig builds. The company specializes in converting outdated DC technology and SCR drives to high-efficiency AC power with Variable Frequency Drives (VFDs), which deliver cleaner and more reliable power to drilling rigs. With around 80% of the installed customer base still using SCR drives, the potential for efficiency gains through VFD upgrades is immense.

To ensure equipment operates at peak efficiency, NOVA provides around-the-clock field engineering support, regional rig repairs, and recertification services. For operators interested in replacing older shaker systems, the Alpha Shaker can be installed in just one day without requiring hazardous hot work. Thanks to its compatibility with most existing King Cobra™ shaker skids, this quick setup minimizes downtime while immediately enhancing fluid recovery and reducing waste haul-off needs.

From Oil Rigs to Carbon Storage: Noble’s Bold Shift to Net Zero

Conclusion

The oil and gas sector faces an urgent need to improve energy efficiency to curb emissions. In fact, energy efficiency measures alone could account for up to 40% of the emissions reductions required to meet the Paris Agreement goals.

The impact of technological advancements in this area is undeniable. These innovations demonstrate that reducing fuel consumption doesn’t mean sacrificing performance – real-world examples back this up. For instance, one North Sea operator achieved a reduction of 6,800 tonnes of CO₂ emissions per year per rig by adopting hybrid battery solutions. Another operator saved 2,000 cubic meters of diesel annually across six rigs by installing waste heat recovery units.

Meeting the International Energy Agency’s (IEA) Net Zero target demands halving emissions intensity by 2030. With the right combination of equipment upgrades and operational adjustments, this ambitious goal is within reach. The urgency for change is clear, and companies like NOVA Petroleum Services are leading the way by offering practical, cost-effective solutions – whether through retrofitting existing equipment or integrating new technologies.

The industry is already taking action. Operators are modernizing their fleets, phasing out older rigs, and investing in advanced units that maximize output while minimizing energy use. As Lorenzo Simonelli, Chairman and CEO of Baker Hughes, aptly put it:

Our ability to drive economic growth and achieve significant emissions reductions underscores our commitment to sustainable energy development – the balance needed to supply the world with the energy it needs today without adversely impacting the abundance and availability of energy tomorrow.

Adopting energy-efficient rigs isn’t just about meeting regulations; it’s about cutting costs and contributing to a cleaner, more sustainable future. The investments made today will secure compliance and sustainability for the sector in the years to come.

FAQs

How do energy-efficient rigs help reduce emissions and meet environmental standards?

Energy-efficient drilling rigs are built to cut down on fuel use and curb harmful emissions, ensuring compliance with U.S. EPA standards for non-road diesel engines (Tier 4 Final). By retrofitting older rigs with Tier 4-compliant engines – like advanced electric-drive systems – operators can significantly reduce diesel consumption, lower greenhouse gas (GHG) emissions, and still achieve top-tier performance.

These rigs feature state-of-the-art technologies, including smart engine-management systems, advanced exhaust treatments, and the capability to use alternative fuels such as hydrogen or LNG. Additional enhancements, like streamlined rig designs and waste-heat recovery systems, further shrink energy demands. Together, these upgrades can lead to 10–15% lower fuel consumption per rig, helping operators meet emissions regulations, cut operational costs, and support sustainability initiatives.

NOVA Petroleum Services offers the advanced drilling solutions, pumps, and artificial-lift systems you need to retrofit or outfit your rigs with these energy-efficient technologies, keeping your operations compliant and efficient.

How do Variable Frequency Drives (VFDs) improve efficiency and reduce emissions on rigs?

Variable Frequency Drives (VFDs) play a key role in improving the performance of electric motors on rigs by adjusting motor speed to meet the exact demands of a task. Instead of running at a constant full speed, motors equipped with VFDs can operate more efficiently, cutting energy use by 30% to 50%. This eliminates wasted energy and reduces the need for mechanical throttling systems. Additionally, VFDs simplify the rig’s hydraulic and electrical systems, boosting both reliability and overall efficiency.

Beyond energy savings, VFDs help reduce wear and tear on equipment by allowing motors to run at lower speeds when full power isn’t needed. This not only lowers maintenance requirements but also extends the lifespan of key components. They also address common issues like water hammer in fluid systems and protect equipment from torque overloads. These features enable rigs to use less fuel or electricity, lower emissions to meet U.S. environmental standards, and align with ESG goals – all while trimming operational costs.

NOVA Petroleum Services offers VFD-enabled systems that bring these benefits together, providing operators with a reliable way to upgrade rigs for greater efficiency and sustainability.

How do digital tools improve the efficiency and sustainability of drilling operations?

Digital tools are reshaping drilling operations by turning raw sensor data into practical solutions. These tools can help cut fuel consumption, speed up cycle times, and reduce emissions. For example, real-time monitoring systems gather data on power usage, engine load, and hydraulic pressure. By analyzing this information, they can pinpoint energy waste and suggest adjustments – like shutting down diesel generators that aren’t needed. The result? Operators can save around $300 per rig daily while also slashing CO₂ emissions.

Automation and machine learning take things a step further by using historical data to fine-tune drilling settings, such as the rate of penetration (ROP) and weight on bit (WOB). These systems make real-time adjustments to improve efficiency and reduce energy consumption. Integrated platforms, such as NOVA’s Aura system, bring together data from various equipment like pumps and motors. This helps operators manage loads more effectively, cut down on idle time, and stay compliant with environmental regulations.

On top of that, advanced monitoring tools enable predictive maintenance by spotting potential equipment issues before they lead to failures. This proactive approach extends the lifespan of components, reduces the need for replacements, and lowers the carbon footprint of operations. By continuously analyzing and refining energy use, these technologies help drilling rigs meet both performance and environmental targets.