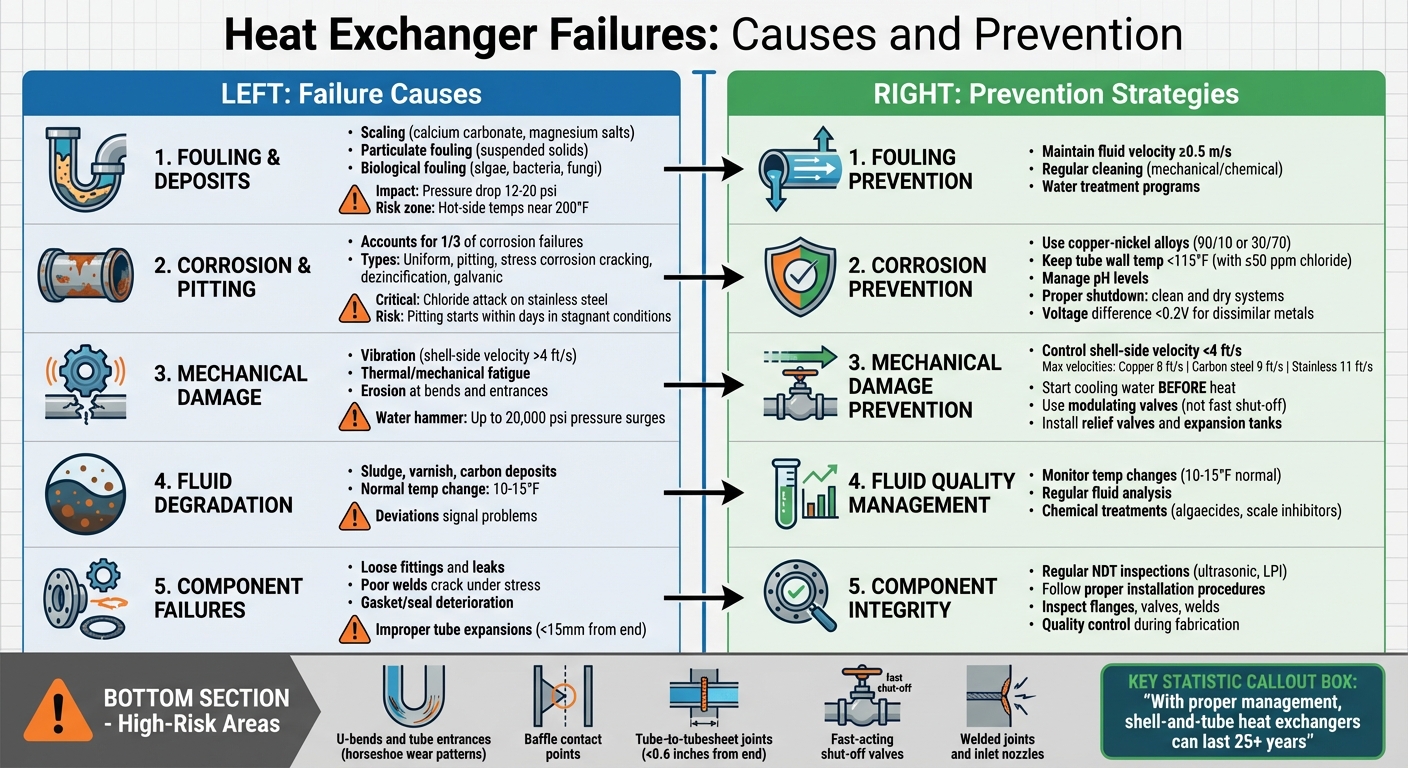

Heat exchangers are critical for maintaining temperature control in oil and gas operations, but when they fail, the consequences can be severe. Failures lead to expensive repairs, unplanned downtime, safety risks, and even catastrophic damage. The main culprits? Fouling, corrosion, mechanical damage, fluid degradation, and component failures. Each issue stems from specific causes like mineral scaling, pitting, vibration, or poor material choices.

Preventing these problems requires regular maintenance, monitoring fluid quality, smart material selection, and proper system design. For example:

- Fouling: Regular cleaning and maintaining fluid velocity above 0.5 m/s.

- Corrosion: Use corrosion-resistant materials like copper-nickel alloys and manage pH levels.

- Mechanical Damage: Control vibrations, avoid pressure surges, and inspect high-stress areas like U-bends.

- Fluid Degradation: Monitor temperature changes and perform regular fluid analysis.

- Component Failures: Inspect connections, seals, and welds for early signs of wear.

Heat Exchanger Failure Causes and Prevention Strategies

Preventing Failures in shell and tube heat exchangers

Main Causes of Heat Exchanger Failures

Understanding the reasons behind heat exchanger failures is key to avoiding expensive repairs and downtime. Most failures result from a few common issues that often develop over time.

Fouling and Deposits

Fouling acts like an unwanted layer of insulation on heat transfer surfaces. As Clayton Penhallegon, Jr., P.E. from Integrated Services Group puts it:

Fouling is like putting a layer of insulation on the heat exchanger surface. It frequently leads to compounding conditions that get progressively worse with accelerating bad performance.

There are three main types of fouling:

- Scaling: Minerals like calcium carbonate and magnesium salts precipitate out of the fluid and form hard deposits.

- Particulate fouling: Suspended solids settle on surfaces, creating blockages.

- Biological fouling: Algae, bacteria, and fungi create organic films.

These deposits increase pressure drop, which typically ranges from 12 to 20 psi, and reduce efficiency. Heat exchangers in air compressors, which often operate with hot-side temperatures near 200°F, are particularly vulnerable to mineral scaling. This buildup forces operators to either accept reduced performance or use more pumping power.

To combat fouling, maintaining minimum fluid velocities (at least 0.5 m/s for certain alloys) and implementing regular water treatments, along with scheduled mechanical or chemical cleaning, are effective strategies . Routine cleaning and monitoring are essential to keeping fouling under control.

Corrosion and Pitting

Corrosion is another major culprit in heat exchanger failures. Murad Ali from Khalifa University‘s Department of Mechanical Engineering notes:

Corrosion is the primary cause of failure of heat exchangers in industry, especially in the oil and petrochemical sector.

Uniform corrosion alone accounts for about one-third of corrosion-related failures. Pitting, however, is particularly dangerous because it focuses damage in small, hard-to-detect areas. John Boyer and Jim Klimek from Xylem explain:

The oxygen-starved pit acts as an anode while the unprotected metal surface serves as a cathode.

This localized reaction can quickly eat through metal, especially during shutdowns when stagnant conditions encourage concentration cells to form.

Different types of corrosion target specific materials and situations. For instance, stress corrosion cracking occurs in areas of high residual stress, like U-bends or tube-to-tubesheet expansions. Chlorides can attack stainless steel, while ammonia affects copper alloys. To minimize this, tube wall temperatures should stay below 115°F in environments with up to 50 ppm chloride concentrations.

Other forms of corrosion, like dezincification, remove zinc from copper-zinc alloys, leaving behind weakened structures. When dissimilar metals are joined in the presence of an electrolyte, galvanic corrosion may occur if the voltage difference exceeds 0.2 V.

Proper shutdown procedures – cleaning and drying systems – are vital, as pitting can start within just a few days . Using copper-nickel alloys (90/10 or 30/70) instead of standard copper offers better resistance to ammonia-induced stress corrosion cracking. A strong water treatment program that manages pH, dissolved gases, and biological growth is also crucial, especially in open-circuit cooling systems . Regular inspections and smart material choices are key to avoiding corrosion-related failures.

Mechanical Damage

Mechanical issues, often caused by repeated stress or abrasion, are another frequent source of problems. As Enerquip explains:

Mechanical failures don’t happen overnight – they develop gradually, often showing small warning signs before becoming serious.

Vibration is a common issue. Omari Hussein Sabuni, a mechanical engineer at Kinyerezi Power Plant, highlights:

Vibration is a prevalent problem in heat exchangers that can lead to severe damage if left unaddressed.

When shell-side fluid velocities exceed 4 feet per second, tubes can vibrate, causing them to rub against support baffles or other tubes. This leads to thinning or cracks from fatigue stress . Vibrations can also come from external equipment like compressors, compounding the issue.

Thermal and mechanical fatigue, caused by repeated expansion and contraction cycles, create cracks that grow over time . High-velocity fluids or abrasive particles can erode metal, especially at bends and entrances. Copper can handle velocities up to 8 ft/s, carbon steel up to 9 ft/s, and stainless steel up to 11 ft/s.

Pressure surges, such as those from water hammer, can be catastrophic. These surges may reach pressures as high as 20,000 psi, far exceeding the burst pressure of standard tubes . To avoid this, cooling water flow should start before applying heat, and modulating control valves are better than fast-acting shut-off valves . Good system design and vibration control are critical to minimizing mechanical damage.

Fluid Degradation

Over time, heat transfer fluids can break down, leading to issues like sludge, varnish, or carbon deposits that settle on heat transfer surfaces and reduce efficiency .

Temperature monitoring is essential. Cooling water should typically change by about 10 to 15°F as it moves through the exchanger. Any deviations could signal fouling or fluid degradation. Regular fluid analysis can catch chemical breakdown early, preventing bigger problems down the line.

Component Failures

Failures at connections, seals, and joints can be just as disruptive as tube issues. Loose fittings at flanges and valves can cause leaks or cross-contamination. Poor welds may crack under thermal cycling or pressure fluctuations, and gaskets and seals can deteriorate when exposed to harsh chemicals or extreme temperatures.

Installation errors often make these issues worse. Improper tube expansions, such as under-rolling or over-rolling, can create leak paths or weaken tube sheet ligaments. Stress tends to concentrate in tube expansions less than 15 mm (0.6 inches) from the tube end, accelerating failure. These problems often go unnoticed until the equipment undergoes its first major thermal cycle or pressure surge, which can cause weakened components to fail.

Regular inspections of flanges, valves, and welded joints can catch problems early. Following proper installation procedures and maintaining strict quality control during fabrication can prevent many of these failures. When repairs are needed, sticking to manufacturer specifications for torque values, expansion techniques, and material compatibility ensures the connections remain secure throughout the equipment’s lifespan.

High-Risk Areas in Heat Exchanger Systems

Identifying areas prone to stress and wear in heat exchanger systems is crucial for effective maintenance and design improvements. By understanding where failures are most likely to occur, you can prioritize inspections and address potential issues before they lead to costly breakdowns. Some parts of heat exchangers endure harsher conditions, higher temperatures, and greater stress, making them more susceptible to early deterioration.

Heater Tubes and Surfaces

Tube entrances and U-bends are particularly vulnerable due to the impact of high-velocity fluids. According to Process Solutions:

The U bend of U-type heat exchangers and the tube entrances are the areas most prone to erosion.

These areas often show "horseshoe" wear patterns caused by turbulence and abrasive particles. Managing fluid velocity is key to minimizing this type of damage.

Baffle contact points are another weak spot. When shell-side fluid velocities exceed 4 feet per second, tubes can vibrate against support baffles, leading to mechanical wear or fatigue cracks. Similarly, tube-to-tubesheet joints face concentrated stress. If tube expansions are placed less than 0.6 inches (15 mm) from the tube end, they are at greater risk of cracking or pullout failures.

Scale and deposits also contribute to hotspots by insulating tube walls. These hotspots can increase corrosion rates and even cause tube ruptures. In steam-to-water exchangers, the outer surfaces of U-bend tubes are especially prone to "condensate grooving", where acidic condensate etches channels into the metal.

Beyond tubes, connection points also demand close attention.

Flanges, Valves, and Fittings

Connection points like flanges, valves, and fittings are often under significant stress in dynamic operating conditions. For instance, fast-acting shut-off valves can trigger water hammer, causing sudden pressure surges that may rupture or collapse standard tubing.

Galvanic corrosion is another risk when dissimilar metals are joined in the presence of an electrolyte. A voltage difference of more than 0.2 volts indicates a high likelihood of corrosion. Additionally, if heated fluid is valved off without a way to absorb thermal expansion, the resulting pressure can crack cast heads or rupture fittings. Vibrations from nearby compressors or motors can also lead to fatigue cracks over time.

Weld quality and pipeline integrity are equally critical to system performance.

Welded Joints and Pipelines

Welded joints are particularly susceptible to failure in heat exchanger systems. Poor welding can leave behind defects that act as starting points for cracks under pressure or during thermal cycling. Many facilities are now dealing with weld-related issues as systems age .

Crevice corrosion often forms in hidden areas, such as between baffles and tubes or under scale deposits, where stagnant conditions create localized electrochemical cells that weaken the system. Inlet nozzles are another vulnerable area, as high-velocity fluids or wet gases can cause impingement erosion when they strike tube surfaces directly. Fixed-tube-sheet designs, which transfer thermal expansion stress directly to welds and tube sheets, are particularly at risk. In contrast, U-tube designs allow for more flexibility, reducing stress on these components .

Regular inspections using non-destructive examination techniques can pinpoint weld defects early, helping to avoid unplanned shutdowns.

sbb-itb-325a090

How to Prevent Heat Exchanger Failures

Avoiding issues like fouling, corrosion, and mechanical damage in heat exchangers requires a proactive approach. By focusing on fluid quality, regular maintenance, and thoughtful system design, you can extend the lifespan of your equipment and minimize costly downtime.

Fluid Quality and Management

Managing the quality and flow of fluids is crucial to preventing fouling and erosion. Controlling fluid velocity helps reduce mineral buildup and discourages biological growth on tube surfaces. However, velocities must stay within safe limits to avoid erosion. For example, copper tubes shouldn’t exceed 8 ft/s, carbon steel 9 ft/s, and stainless steel or 90/10 copper-nickel alloys 11 ft/s.

Chemical treatments also play a key role. Using algaecides like chlorine helps control biological growth, while scale inhibitors prevent mineral deposits from forming on heat transfer surfaces. Additionally, keeping tube wall temperatures below 115°F (46°C) can prevent stress corrosion cracking in environments with chloride concentrations up to 50 ppm.

Monitoring changes in pressure drop and temperature (a 10°–15°F shift) can indicate early signs of fouling. Pair these efforts with regular inspections to ensure the system runs smoothly.

Routine Inspections and Maintenance

Scheduled inspections are essential for catching potential issues before they lead to failure. With proper management of materials, process chemistry, and maintenance, shell-and-tube heat exchangers can last 25 years or more. Non-destructive testing (NDT) methods like ultrasonic testing and Liquid Penetrant Inspection (LPI) help detect flaws early. For exchangers with removable bundles, inspect the entire bundle; for fixed bundles, remove channel covers to check internal components.

Follow proper startup and shutdown protocols to avoid sudden pressure surges of up to 20,000 psi. For instance, always start the cooling water flow before applying heat to the exchanger to prevent stagnant water from boiling, which could cause water hammer. During shutdowns, clean and prepare the heat exchanger thoroughly to avoid pitting corrosion, which can start within days in stagnant conditions. Relief valves and expansion tanks can also help absorb fluid expansion caused by thermal cycling.

System Design and Material Selection

The right materials and design features can prevent corrosion and mechanical stress, significantly improving the durability of your heat exchanger. Material compatibility is key. When joining dissimilar metals, ensure the voltage difference is less than 0.2 volts to avoid galvanic corrosion. Additionally, use brass with less than 85% copper or alloys containing tin or arsenic to prevent dezincification in stagnant or oxygen-rich environments. Copper-nickel alloys are better suited for environments where ammonia is present.

Design features also play a big role in reducing stress-related failures. For example, U-tube designs allow the tube bundle to expand and contract independently, minimizing thermal stress, while fixed-tube-sheet designs transfer stress directly to welds and tube sheets. Keep shell-side fluid velocities below 4 ft/s to avoid vibration-induced tube damage at baffle contact points.

To protect against sudden pressure changes, consider mechanical safeguards. Replace fast-acting shut-off valves with modulating control valves to prevent water hammer. Oversize inlet nozzles or install impingement baffles to protect tube exteriors from erosion caused by wet, high-velocity gases. For shell-side nozzle velocity, follow this formula to avoid impingement erosion: ρ × V² ≤ 1,500 (where ρ is fluid density in lb/ft³ and V is velocity in ft/s).

Lastly, opt for removable bundle designs when possible, as they make internal inspections and cleaning much easier compared to fixed-bundle configurations. Smooth surface finishes on alloys like AISI 304 can also help reduce pitting corrosion in chloride-rich environments.

Safety Considerations for Heat Exchanger Operations

Failures in heat exchangers can lead to serious risks for both personnel and equipment. Addressing these dangers with effective safety measures is essential to ensure smooth and secure operations.

Auto-Ignition and Vapor Hazards

Fluid leaks can result in the buildup of flammable vapors, creating fire and explosion risks if ignited. To minimize these dangers, grounding systems are essential to prevent static-induced ignition. For high-temperature systems – like air compressor heat exchangers operating above 200°F (93°C) – it’s critical to install temperature alarms, control mechanisms, and automatic shutoff systems to prevent overheating and potential auto-ignition. Explosion relief and vent systems can further help by managing vapor accumulation before it becomes hazardous. Additionally, implementing strict hazard classifications and leak detection systems enables quick isolation of affected units.

These precautions help establish a solid defense against sudden pressure-related events, which are discussed below.

Pressure System Safety

Pressure surges in heat exchangers can exceed the structural limits of tubes, leading to potential failures. For example, when a heated fluid is trapped without an outlet for thermal expansion, the stress can surpass the material’s tensile strength, causing cracks or ruptures. To counteract this, relief valves, expansion tanks, and vacuum breaker vents are essential for managing sudden pressure changes. In systems with varying fluid qualities, maintaining a constant pressure differential is crucial. Keeping the "clean" fluid side at a higher pressure not only aids in early leak detection but also prevents cross-contamination.

Personnel Protection During Maintenance

Protecting workers during maintenance is just as important as safeguarding the equipment.

Maintenance tasks often expose workers to risks like pressurized fluids, corrosive chemicals, and heavy machinery. A Permit to Work (PTW) system ensures that all safety protocols are reviewed and approved before high-risk activities begin. To further reduce risks, equipment should be mechanically and electrically isolated to prevent unexpected hazardous releases. Personnel must wear appropriate personal protective equipment (PPE) and undergo training tailored to the specific maintenance tasks and potential failure scenarios. Additionally, lifting procedures and emergency spill response plans should be clearly established before starting any maintenance work.

Conclusion

Heat exchanger failures often arise from corrosion, mechanical stress, and fouling, each of which can disrupt production and compromise safety. Corrosion leads to issues like pitting and stress cracking, while mechanical damage stems from pressure surges or inadequate material strength. Fouling, on the other hand, acts as an insulator, reducing efficiency and accelerating wear over time.

Preventing these failures requires a proactive, focused approach. Regularly monitoring pressure drops and heat transfer coefficients is crucial for spotting problems early, enabling scheduled maintenance rather than costly, unplanned shutdowns. As John Boyer and Jim Klimek from Xylem explain:

An efficient heat-transfer system plays a key role in cost-effective manufacturing – while a heat exchanger failure can lead to costly downtime.

By taking such steps, you can save energy and extend the lifespan of your equipment. Choosing the right materials and installing system safeguards – like relief valves and expansion tanks – can stop damage before it starts, avoiding expensive tube replacements. Additionally, root cause analysis (RCA) is essential for identifying patterns in recurring failures. As Siddharth Talapatra and Andrew J. Mountford emphasize:

Effective root cause analysis (RCA) can resolve recurring heat exchanger tube failure, enabling safe operation and reducing costs.

Incorporating these strategies into your operations not only prolongs the life of your equipment but also enhances workplace safety. These preventative measures turn potential weak points into reliable assets, protecting both your investment and your team. Prevention, in this context, is more than a technical solution – it’s a critical element of sound business practice.

FAQs

What are the main causes of heat exchanger fouling, and how can they be prevented?

Heat exchanger fouling happens when substances like mineral scales, suspended particles, biological growth (such as algae), corrosion byproducts, or chemical deposits accumulate on the equipment. When left unchecked, these buildups can drag down efficiency, push energy costs higher, and even cause equipment to break down.

Keeping fouling at bay requires consistent maintenance. This means cleaning the system to clear out deposits, installing effective filtration systems to catch particles, and treating water to minimize scaling and biological growth. Using materials that resist corrosion and closely monitoring operating conditions can also go a long way in maintaining performance and reliability over time.

What are the best ways to prevent corrosion in heat exchangers?

Corrosion in heat exchangers can cause leaks, lower efficiency, and even pose safety hazards. To address these challenges, focusing on material selection, protective coatings, chemical control, and proactive monitoring is essential.

Choosing corrosion-resistant materials like duplex stainless steel or titanium can prevent problems such as pitting and stress-corrosion cracking. Protective coatings, such as epoxy or galvanized layers, act as a shield, safeguarding metal surfaces from aggressive fluids. Keeping fluid chemistry in check – by managing pH, dissolved oxygen, and chloride levels – further reduces the risk of corrosive reactions. For systems prone to microbiologically induced corrosion (MIC), eco-friendly inhibitors, like those based on essential oils, offer an effective solution.

Advanced monitoring tools, including predictive maintenance technologies, make it easier to spot early signs of corrosion, allowing for timely action. Companies like NOVA Petroleum Services provide corrosion-resistant components, state-of-the-art coatings, and custom inhibitor programs to help heat exchangers perform reliably and safely under the tough conditions of U.S. oilfields.

What are the best practices for ensuring fluid quality in heat exchangers?

Maintaining top-notch fluid quality is essential to avoid problems like fouling, corrosion, and wear – issues that can seriously impact the efficiency of your heat exchanger. To start, make sure to filter the fluid regularly. This helps remove solids, debris, and emulsified water that can cause trouble. Keep an eye on critical parameters like pH, hardness, dissolved salts, and inhibitor levels by conducting routine sampling and testing. Staying within the recommended ranges for temperature, pressure, and velocity is also key to preventing scale buildup and metal erosion.

A solid cleaning routine is just as important. For shell-and-tube heat exchangers, chemical cleaning agents work well to eliminate scale and deposits without harming the equipment. Plate-type exchangers, on the other hand, can often be cleaned in place (CIP) or manually scrubbed when necessary. To go a step further, use corrosion inhibitors that match the fluid’s chemistry and operating conditions. This can go a long way in extending the life of your system.

NOVA Petroleum Services offers top-tier filtration systems, water treatment chemicals, and corrosion inhibitors that integrate seamlessly with your heat exchanger setup. By combining effective filtration, chemical management, and routine maintenance, you can ensure consistent performance, minimize downtime, and keep operations running safely.