Mechanical pigging is the go-to solution for tackling wax build-up in crude oil pipelines. Wax forms when oil cools, sticking to pipe walls and narrowing flow. Left unchecked, this can cause blockages, increase pressure, and lead to costly repairs or downtime. Pigging involves sending a device (the pig) through the pipeline to scrape off wax deposits effectively.

Key Takeaways:

- Wax Formation: Occurs when oil temperature drops below the Wax Appearance Temperature (WAT), leading to paraffin deposits.

- Pigging Process: Pigs are inserted into pipelines and propelled by oil flow to remove wax layers. They use sealing discs, brushes, or studs to scrape deposits.

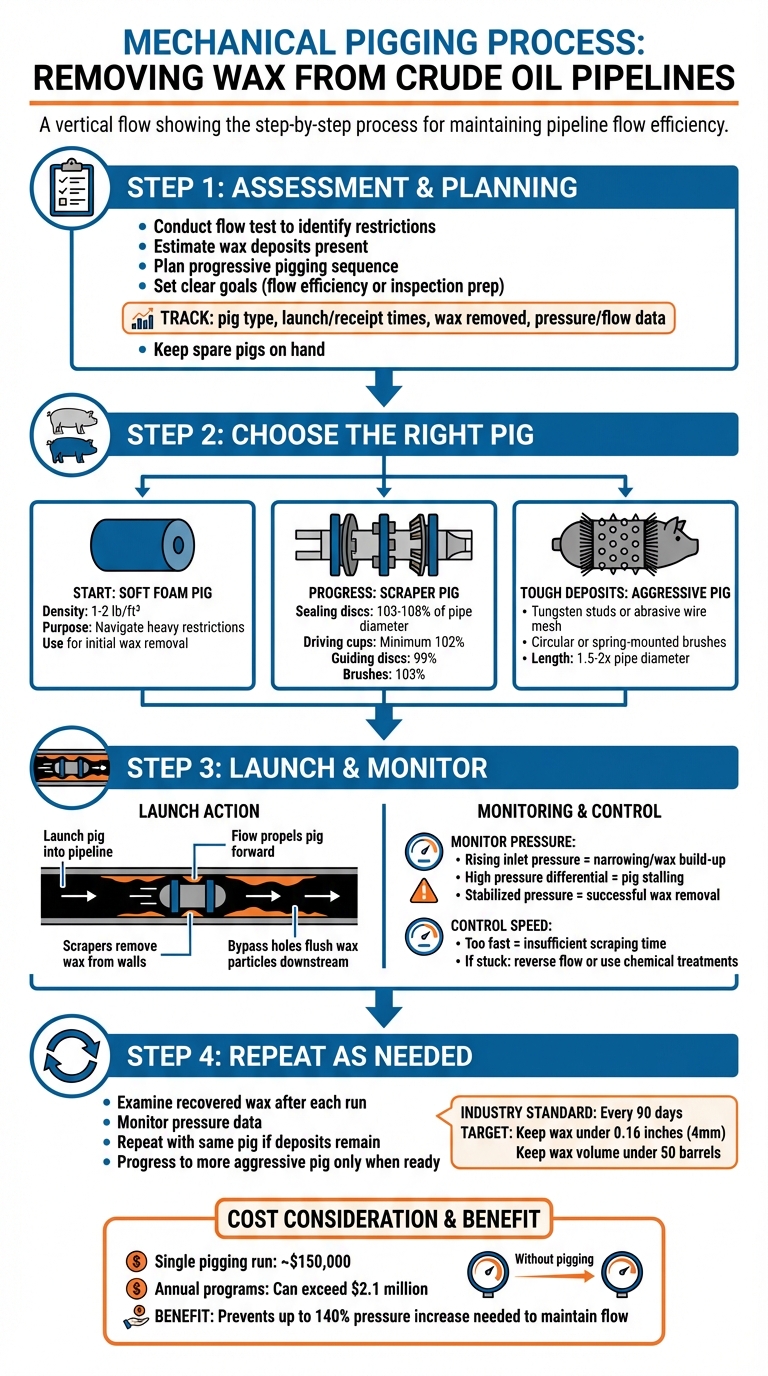

- Costs: A single pigging run costs ~$150,000; annual programs can exceed $2.1 million.

- Frequency: Industry suggests pigging every 90 days to keep wax layers under 0.16 inches.

- Benefits: Maintains flow rates, reduces pressure build-up, prevents corrosion, and extends pipeline lifespan.

Mechanical pigging is a reliable method for keeping pipelines clear and efficient, ensuring safe and uninterrupted operations.

Pipeline Pigging in Action | How Pigs Clean Pipelines!

sbb-itb-325a090

How Mechanical Pigging Prevents Wax Build-Up

Mechanical pigging is an effective method for tackling wax deposits in pipelines. It involves sending a physical device, known as a pig, through the pipeline, propelled by the pressure of flowing crude oil. As the pig moves, it scrapes and scours the pipe walls, breaking up wax deposits along its path.

How the Scraping Process Works

The pig’s design is crucial for removing wax effectively. Sealing discs on the pig are slightly oversized – typically 103% to 108% of the pipe’s internal diameter. This ensures they maintain constant contact with the pipe walls, scraping away deposits as the pig moves forward. For tougher paraffin layers, pigs can be fitted with tungsten studs or abrasive wire mesh, which grind through hardened wax.

The process often follows a "progressive pigging" approach. Operators begin with soft foam pigs (weighing around 1–2 lb/ft³) to break up softer wax deposits. Once the initial layer is cleared, they switch to more aggressive mechanical pigs to tackle compacted wax. This staged method reduces the risk of the pig becoming stuck in heavy wax build-up.

How Often to Run Pigs

Consistency is key to preventing wax from hardening into difficult-to-remove layers. As wax ages, it solidifies and forms a gel-like network that becomes increasingly stubborn. To avoid this, industry standards suggest maintenance pigging every 90 days under normal conditions. The target is to keep wax thickness below 0.16 inches (4 mm) and ensure the wax volume ahead of the pig stays under 50 barrels to avoid blockages. These regular runs help maintain the pipeline’s performance and efficiency.

Benefits of Mechanical Pigging

The advantages of regular pigging are far-reaching. First, it keeps the pipeline at full capacity, avoiding the need for up to a 140% pressure increase to maintain flow. Second, it minimizes production downtime and reduces pressure drops. Third, removing wax eliminates the risk of under-deposit corrosion and microbiologically induced corrosion (MIC), where trapped bacteria can degrade the pipe’s metal. By addressing these issues, pigging extends the pipeline’s lifespan and lowers the risk of costly repairs or replacements.

Step-by-Step Guide to Mechanical Pigging

Mechanical Pigging Process: Step-by-Step Guide to Removing Wax from Pipelines

Assessment and Planning Before Pigging

Preventing wax build-up starts with thorough planning before deploying a pig. Begin with a flow test to confirm fluid movement through the pipeline. This test helps identify any restrictions and gives an estimate of the wax deposits present. Plan a step-by-step sequence using pigs of increasing aggressiveness. This method removes wax in layers, lowering the chance of the pig getting stuck. Clearly define your goals – whether it’s maintaining flow efficiency or prepping the line for an inspection tool – and set up a data collection process before the first run. Track key details like the type of pig used, launch and receipt times, the amount and type of wax removed (photos help here), and pressure and flow data for each run. Always have spare pigs on hand to adapt quickly based on the results of each run. With these preparations, you can confidently choose the right pig for your pipeline conditions.

Choosing the Right Pig Type

When starting with a pipeline that may have significant wax build-up, begin with a soft foam pig, typically with a density of 1–2 lb/ft³. These pigs are designed to navigate heavy restrictions without getting stuck. If the first run removes a large amount of wax or results in a noticeable pressure drop, you may need to repeat the process with another foam pig before moving to a more aggressive type.

Once the softer deposits are cleared, transition to scraper pigs equipped with polyurethane discs or cups. The components of these pigs must be precisely sized to ensure effective operation:

- Sealing discs should be 103%–108% of the pipe’s internal diameter to create a proper seal for propulsion.

- Driving cups need to be at least 102% to provide sufficient propulsion force.

- Guiding discs should be 99% to keep the pig centered.

For tougher wax deposits, use pigs with circular or spring-mounted brushes, sized to 103% of the pipe diameter. To prevent rolling, the pig’s length should be about 1.5 to 2 times the pipe’s nominal diameter.

| Pig Component | Sizing (% of Pipe ID) | Purpose |

|---|---|---|

| Sealing Discs | 103%–108% | Ensures proper seal for propulsion |

| Driving Cups | Minimum 102% | Provides the propulsion force |

| Guiding Discs | 99% | Centers the pig within the pipe |

| Gauge Plates | 95% | Detects internal diameter restrictions |

| Brushes | 103% | Scrapes and removes hard wax deposits |

Running and Monitoring the Pig

After selecting the appropriate pig, launch it into the pipeline and allow the flow to propel it forward. As the pig moves, its scrapers will remove wax from the pipe walls. Many pigs include bypass holes that let some fluid pass through, helping to flush wax particles downstream and avoiding blockages ahead of the pig.

Keep a close eye on pressure readings at both the inlet and outlet. If the inlet pressure starts to rise, it could indicate narrowing or wax build-up in the pipeline. A high pressure differential might mean the pig is stalling or encountering a wax plug. In such cases, adjust the flow rate to help the pig move forward. Once the pressure stabilizes, it’s a good sign that wax removal has been successful.

Control the pig’s speed carefully – if it moves too fast, it won’t have enough time to scrape and flush away deposits effectively. If the pig becomes stuck, you can try reversing the flow direction or using chemical treatments to soften the wax in front of the pig.

Best Practices for Pigging Programs

Mechanical pigging is a proven method for maintaining pipeline performance, but following a set of best practices can make operations even more efficient and effective.

Progressive Pigging Approach

Start with the softest pig available and gradually move to more aggressive designs. This step-by-step process removes wax in layers, reducing the chance of a pig getting stuck. For heavy wax deposits, begin with a soft foam pig (1–2 lb/ft³), as mentioned earlier. These are designed to compress and navigate restrictions, safeguarding your pipeline.

After each pigging run, examine the recovered wax and monitor pressure data. If significant deposits remain or pressure drops are detected, repeat the process with the same pig. Avoid skipping stages in the pigging sequence, as this can lead to blockages. The key here is patience – allow each pig to handle its share of the work before advancing to the next level of aggressiveness. This methodical approach not only minimizes risks but also helps refine future pigging schedules.

Setting the Right Pigging Schedule

The frequency of pigging runs depends on how quickly wax builds up in your pipeline. Rising pressure is a clear indicator that it’s time for a pigging run.

Use historical data from previous pigging operations to establish a baseline. Keep detailed records of the wax removed, including its type and quantity, and document findings with photos. This information allows you to anticipate when the next pigging run will be needed. Additionally, chemical inhibitors can significantly reduce the frequency of pigging – by as much as 50% in some cases. For instance, one operation combined chemical treatments with optimized pigging schedules and cut annual wax management costs by about 31%.

Coordinating Pigging with Production

For the best results, align pigging schedules with production activities to maintain steady flow and optimal conditions. Plan pigging runs when the pipeline is operating at its highest temperature, as warmer pipe walls improve wax removal. Work closely with production teams to ensure adequate flow rates during pigging, as the pig requires consistent pressure to avoid stalling.

If you’re using chemical treatments, coordinate their timing with pigging runs. For example, apply wax inhibitors before the crude oil temperature drops below the Wax Appearance Temperature (WAT). Then, follow up with mechanical pigging to clear any remaining deposits. Keep in mind that a single pigging run can cost approximately $150,000. By synchronizing pigging with chemical treatments or continuous injection programs, you can manage costs more effectively and reduce disruptions to production.

Conclusion

Mechanical pigging plays a crucial role in keeping pipelines running smoothly and efficiently. By clearing wax deposits before they become problematic, it avoids the need for significant pressure increases – sometimes as much as 140% – to maintain flow rates. Industry guidelines suggest keeping wax buildup under 4 mm thick and limiting the volume of wax ahead of the pig to under 50 barrels to prevent blockages.

Beyond maintaining flow, regular pigging also protects pipelines from under-deposit corrosion and microbiologically induced corrosion (MIC). These issues can drastically reduce the lifespan of your infrastructure, leading to expensive repairs or even premature replacement. As GATE Energy explains:

"Build-up of deposits can create conditions for accelerated localized corrosion… This may result in sections of the pipeline needing repair or replacement before the end of their anticipated design life."

To get the most out of mechanical pigging, it’s essential to pair it with smart operational strategies. A step-by-step pigging plan – starting with soft foam pigs and progressing to more aggressive options – works best. Use data from pressure monitoring and wax removal records to create a precise pigging schedule. Coordinate pigging with chemical treatments and production timelines to maximize results and reduce downtime. For ongoing maintenance, pipelines should typically be pigged every 90 days. These practices not only maintain efficient production but also help extend the lifespan of your pipeline system.

FAQs

How does mechanical pigging help prevent wax buildup and protect pipelines?

Mechanical pigging is a hands-on way to keep pipelines clear of wax buildup. It involves using tools called pigs, which are inserted into the pipeline. As these pigs move through the system, they scrape away wax, debris, and other deposits that can clog the flow or lead to blockages.

Regular pigging does more than just keep things flowing smoothly. It also helps prevent corrosion by removing trapped moisture and contaminants. This kind of routine maintenance not only keeps pipelines running efficiently but also reduces the chances of expensive repairs and downtime, ultimately extending the pipeline’s lifespan.

What determines how often mechanical pigging should be performed?

The need for mechanical pigging largely hinges on how quickly wax builds up in a pipeline. This build-up is influenced by factors like the crude oil’s wax appearance temperature, the pipeline’s temperature, flow speed, and the surrounding environment. For instance, pipelines exposed to colder conditions or transporting wax-heavy crude oil often require more frequent pigging to avoid blockages.

Other key factors include the pipeline’s specific features – such as its diameter, length, and flow rate – and operational challenges, like the availability of pigging tools or the cost of maintenance. Historical data, including previous pigging outcomes and wax accumulation trends, also play a crucial role in fine-tuning the pigging schedule. By carefully weighing these elements, operators can develop a plan that effectively minimizes wax build-up without overdoing maintenance.

NOVA Petroleum Services offers top-notch mechanical pigs and cutting-edge designs to help operators streamline their pigging intervals and keep pipelines running smoothly.

How can mechanical pigging and chemical treatments work together to improve pipeline efficiency?

Combining mechanical pigging with chemical treatments can make wax removal in pipelines much more effective, cutting down on the need for frequent pigging. By applying chemicals to soften or dissolve wax before pigging, operators can achieve cleaner pipelines with less effort and downtime.

For the best results, time chemical injections to occur just before a pigging run. Choose products that work well with the pipeline’s conditions and the pig’s material. Inject the chemical upstream of the pig’s launch point, giving it enough time to break down the wax. When the pig is launched, it will not only clear out the softened wax but also help spread the chemical further along the pipeline, enhancing the overall cleaning process.

Keep an eye on key metrics like wax buildup thickness and pigging pressure to fine-tune the method and ensure steady, efficient pipeline flow. This combined approach provides a practical and efficient way to tackle wax buildup in pipelines across the U.S.