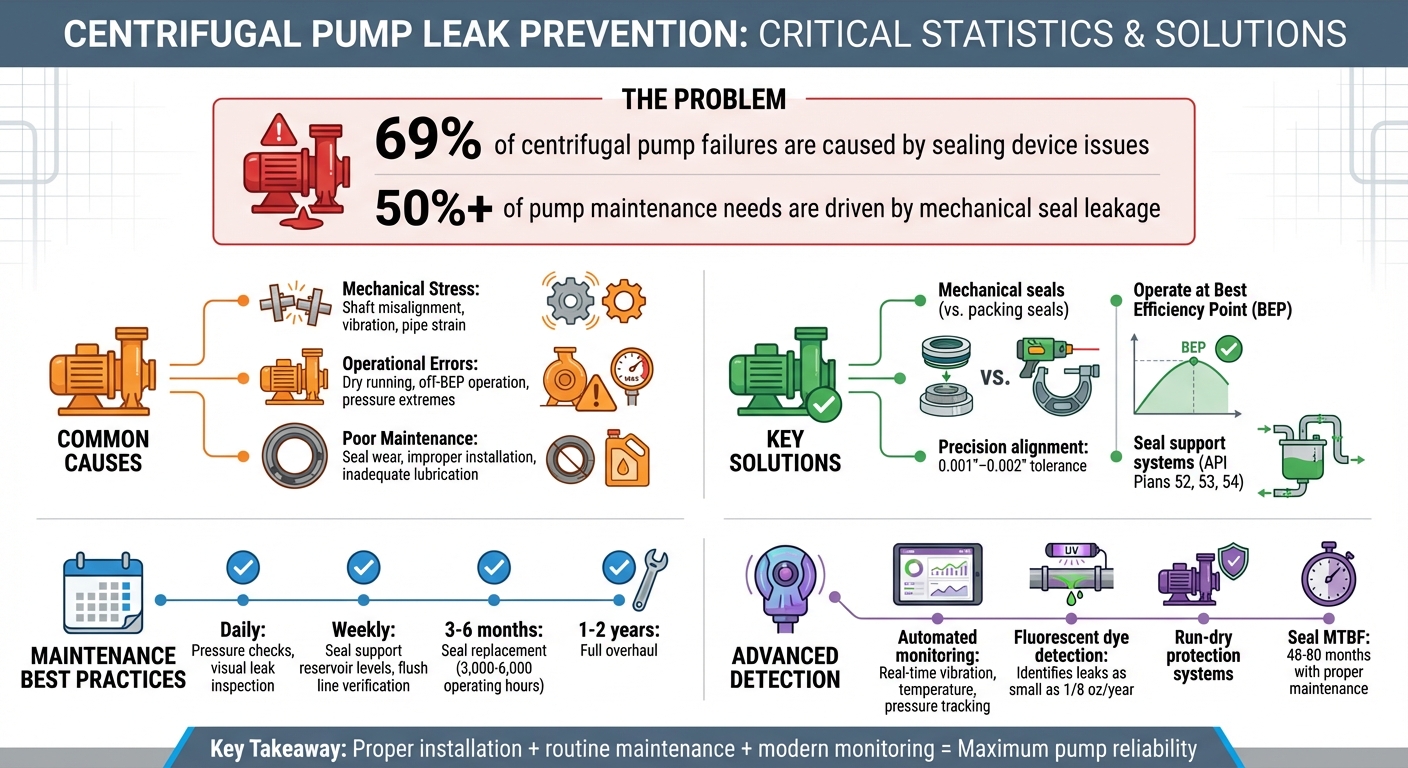

Centrifugal pump leaks are a leading cause of failures, with 69% of issues tied to seal malfunctions. Preventing leaks ensures efficiency, safety, and compliance with strict regulations. Here’s what you need to know:

- Common Causes: Seal wear, shaft misalignment, dry running, and improper maintenance.

- Key Solutions: Use mechanical seals for better performance, maintain proper alignment, and monitor for vibration or temperature changes.

- Advanced Tools: Automated monitoring systems and fluorescent dye detection help catch leaks early.

- Best Practices: Regular inspections, precise installation, and routine maintenance extend pump life and reduce downtime.

Preventive measures like seal upgrades and support systems save costs over time. Investing in proper maintenance ensures pumps run reliably and meet safety standards.

Centrifugal Pump Leak Prevention: Key Statistics and Solutions

How Mechanical Seals Prevent Leakage in Pumps | Working Explained

Common Causes of Leaks in Centrifugal Pumps

Understanding why leaks happen is key to preventing them. Most issues fall into three broad categories: mechanical stress, operational errors, and poor maintenance. Frank Rotello, a Mechanical Seal Reliability Engineer at Cummins-Wagner, points out that about 69% of centrifugal pump failures stem from sealing device issues. By identifying these root causes, operators can address problems early, avoiding expensive downtime. These factors also provide a foundation for exploring sealing solutions and troubleshooting techniques.

Mechanical Stress and Misalignment

Shaft misalignment is a major culprit. Misalignment widens the critical 5–50 microinch seal gap, and when combined with vibrations from loose mounts, damaged impellers, or worn bearings, it quickly compromises seal performance. Paul Lesnau, Sales Manager and Field Engineer at Swagelok Northern California, explains:

"Alignment or bearing problems that induce vibrations can also be wreaking havoc with a mechanical seal, causing leaks".

Pipe strain complicates things further. When improperly aligned piping is bolted directly to the pump, it distorts the casing and undermines the seal’s integrity. Foundation issues, such as a "soft foot" – where one or more mounting feet fail to make even contact with the baseplate – can shift the entire assembly during operation.

Extreme temperatures and pressures can warp seal faces, disrupting the flat surface needed for an effective seal. Additionally, unbalanced impellers create centrifugal forces that strain both the shaft and sealing components.

Operational Factors

Dry running is one of the most common causes of seal failure. Without fluid to cool and lubricate the seal faces, heat builds up rapidly, leading to mechanical damage. Operating the pump far from its Best Efficiency Point (BEP) introduces flow instability, turbulence, and excessive heat. Dead-heading, or restricting flow too much, can cause fluid to recirculate inside the pump, overheating and damaging seals.

Pressure extremes can deform seal faces and damage secondary parts like O‑rings and bellows. Temperature swings can result in "coking" (carbon buildup on seal faces) or "heat checking" (circular cracks on the surface). For hot fluids like boiler feed water or hydrocarbons, a sudden pressure drop can cause the fluid to vaporize, destroying the lubricating film between seal faces.

Changes in fluid viscosity also impact lubrication. If viscosity shifts unexpectedly, the seal faces might not receive adequate lubrication, leading to increased friction and heat.

Maintenance and Wear Issues

Over time, seals naturally wear down. Elastomeric components – like O‑rings, V‑rings, and gaskets – tend to degrade faster than metal parts due to erosion, fretting, or chemical exposure. Using the wrong lubricant or failing to maintain the fluid film between seal faces can generate friction and heat, eventually causing cracks.

Improper installation is another issue. For example, touching seal faces with bare hands introduces contaminants like body oils, while failing to follow torque specifications weakens seal integrity. The PumpWorks Engineering Team emphasizes:

"Misalignment will cause premature mechanical seal failure".

Precision alignment – within 0.001" to 0.002" – is critical during installation or maintenance.

SEPCO underscores a vital maintenance rule:

"The most crucial consideration to avoid multiple mechanical seal repairs is never to let the seal dry out".

Routine vibration monitoring can detect bearing wear and shaft imbalance before they compromise the seal. Ensuring the pump base is secure, properly grouted, and free of soft foot conditions also reduces operational stress.

Sealing Technologies for Leak Prevention

Preventing leaks often hinges on choosing the right sealing technology. This section explores two primary options – packing seals and mechanical seals – each with distinct designs, costs, and performance characteristics. The choice depends heavily on your application, the type of fluid being handled, and your maintenance capabilities. Picking the wrong seal can lead to unnecessary product loss, environmental concerns, and even equipment damage.

Packing Seals

Packing seals, also known as gland packing, rely on braided fibers or rubber rings placed around the shaft inside a stuffing box. These seals allow controlled leakage, which is critical for lubrication and cooling. Without this leakage, the packing could overheat and fail quickly.

To enhance performance, a lantern ring is often added to distribute flush water evenly, ensuring proper cooling and lubrication. Packing seals are particularly effective for large slurry pumps or mining operations where particles are present, and significant shaft movement (both radial and axial) is expected. They are also more forgiving of misalignment and vibration and can be installed without disconnecting the drive shaft.

However, packing seals come with drawbacks. They require frequent manual adjustments as the material wears down and constant cleanup of leaked product. Over time, the packing can wear down the shaft sleeve, leading to expensive repairs. Raman Hanjra, Global Product Line Manager at A.W. Chesterton Company, highlights a key limitation:

"Packing cannot be 100% leak free. Even when leakage isn’t visible, harmful vapors could be escaping."

While packing seals may appear cost-effective upfront, ongoing expenses related to product loss, water usage, and labor-intensive maintenance can quickly add up.

Mechanical Seals

Mechanical seals feature two polished, lapped faces – one stationary and one rotating – held together by spring or hydraulic pressure. These surfaces create an almost perfect seal, allowing only tiny amounts of vapor to escape while maintaining a thin lubricating film. As the PumpWorks Engineering Team notes:

"All mechanical seals leak…vapor."

This minimal leakage makes mechanical seals ideal for handling hazardous, toxic, or high-value fluids. Single mechanical seals work well with non-hazardous fluids, while double mechanical seals, equipped with a barrier fluid, provide additional safety for hazardous processes. Raman Hanjra underscores their importance:

"A mechanical seal, and more specifically a double mechanical seal, should always be used when the pumped fluid presents a safety, health, or environmental hazard."

Mechanical seals also prevent shaft sleeve wear and reduce friction, which can lower power consumption. However, they demand precise conditions for optimal performance. The pump must be in excellent shape, with alignment tolerances within 0.001" to 0.002". Any misalignment or vibration can lead to premature seal failure. Installation is more complex and often requires disconnecting the drive shaft, and the initial cost is significantly higher than packing seals.

Cartridge seals simplify the installation process by integrating all components – seal faces, gland, and shaft sleeve – into one unit. This design minimizes alignment errors and ensures proper face loading, making it a preferred option for facilities with limited technical expertise. Secondary sealing elements like O-rings, PTFE wedges, or V-rings are also used to prevent leakage between the seal components and the pump shaft or housing. These elements must be compatible with the fluid’s temperature and chemical properties.

Seal Support Systems

Both packing and mechanical seals rely on support systems to perform effectively. These systems provide essential flushing, cooling, and pressure regulation to extend seal life and prevent failures. For packing seals, flush water is routed through the lantern ring to ensure even cooling and lubrication within the stuffing box. For mechanical seals, support systems – such as those following API Plans 52, 53, or 54 – manage barrier fluids and help dissipate heat.

Without these support systems, seals are at risk of overheating, drying out, or failing prematurely. When comparing packing and mechanical seals, it’s important to consider not just the upfront cost but also the ongoing expenses tied to flush water and product loss. In many cases, the higher initial investment in mechanical seals proves more economical over time. These support systems are critical for maintaining seal performance and play a key role in future maintenance and troubleshooting efforts.

Troubleshooting and Diagnosing Leaks

Accurately diagnosing leaks early can help prevent expensive repairs or equipment failures. Did you know that 69% of all centrifugal pump failures are caused by sealing device issues? This makes methodical troubleshooting a must. Start by identifying the symptoms and reviewing any visible or operational signs of leaks.

Visible leaks are often the easiest to spot. Look for dripping or spraying around the shaft, seal housing, or flange joints. But not all leaks are obvious. For example, suction-side air leaks might show up as bubbles or foam in the suction line, erratic flow, or even loss of prime rather than leaking fluid. If you notice performance issues – like a drop in pump head, efficiency, or flow rate – it could point to internal leaks caused by worn wear rings or bypassed seals. Don’t ignore unusual noises like rattling, grinding, or recirculation sounds, as these often signal seal or gasket problems. Excessive vibration is another red flag.

Temperature monitoring is another key diagnostic tool. High bearing temperatures – anything over 200°F (93°C) – or localized overheating at the stuffing box might indicate lubrication failure or friction from over-tightened packing. Oil residue on the pump frame, cloudy oil in sight gauges, or visible leaks around the bearing housing are signs of potential seal problems. Frank Rotello, a Mechanical Seal Reliability Engineer at Cummins-Wagner, highlights the importance of seals:

"Mechanical seals are a major factor in rotating equipment reliability. They’re responsible for leaks and failures of the system, but they also indicate problems that would eventually cause serious damage down the road."

Inspecting Packing Glands and Shafts

Packing glands are designed to leak slightly – around 40–60 drops per minute – to ensure proper lubrication. If you see spraying or hear air being pulled into the suction line, the gland likely needs adjustment. Tighten the gland nuts gradually, turning them only one-quarter turn at a time, to avoid over-tightening, which can lead to friction, overheating, and accelerated wear on the packing and shaft sleeve.

Check the shaft sleeve surface for any scoring or wear. A damaged sleeve can compromise sealing and speed up packing deterioration. If the sleeve is worn, replace it before installing new packing. For suction-side air leaks, try this: inject a small amount of liquid from the discharge line into the lantern ring. If the pump’s performance improves, you’ve confirmed an air leak.

Evaluating Flange and Piping Connections

Leaks at flange and piping connections are often due to improper installation rather than faulty components. Inspect for loose bolts and tighten them evenly using a cross-pattern to ensure uniform gasket compression. Watch for signs that the pump is bearing the weight of the piping – this can strain the flange, leading to cracks and leaks. As Cornell Pump points out:

"Pumps should never be used to support piping weight."

To relieve stress on pump connections, install proper pipe supports. On suction piping, use eccentric reducers with the flat side up to avoid air pockets that can cause cavitation and erratic performance. If there’s excessive vibration at flange connections, misalignment is likely the issue. Realign the piping before replacing gaskets to avoid recurring problems.

Diagnosing Mechanical Seal Failures

When diagnosing mechanical seal issues, focus on vibration, temperature, and leakage rate. Mechanical seals typically leak a small amount of vapor for lubrication, but visible liquid leakage or a rapidly increasing leak rate signals failure. Before disassembling, check the suction fluid, measure seal chamber and flush pressures, and listen for cavitation sounds. Infrared scanning can help identify hot spots around the seal chamber.

Vibration analysis is particularly useful for spotting alignment and bearing problems that could damage seals. Ensure the pump and motor are aligned within tight tolerances. To check for “soft feet,” loosen and retighten the foot bolts – if vibration changes, add shims. Confirm that flush pressure is set to 1.5 to 2 bar above seal chamber pressure, and ensure the flush flow isn’t blocked by clogged orifices or coolers.

Deciding whether to stop or keep running depends on the severity of the symptoms. If the flow is within 15% of the target, temperatures are steady, and leakage is stable, you can continue operating. However, stop immediately if you hear severe cavitation (a sound like marbles in the casing), notice oil turning milky or foamy, or see leak rates increasing rapidly. During teardown, inspect the seal faces for heat damage (circular surface cracks) or carbon buildup, as these indicate the seal needs replacement rather than repair.

sbb-itb-325a090

Preventive Maintenance Best Practices

The difference between a pump that runs smoothly for years and one that constantly breaks down often comes down to one thing: consistent preventive maintenance. Instead of waiting for leaks or other issues to show up, taking a proactive approach can catch problems early and significantly extend the life of the equipment. In fact, such practices can push seal Mean Time Between Failures (MTBF) to an impressive 48–80 months.

Routine Inspections and Monitoring

Daily and weekly checks are the backbone of preventing leaks. Regular visual inspections should focus on the pump casing for signs of cracks or corrosion, flange connections for fluid leaks, and mechanical seal faces for any scoring or pitting. Also, keep an eye on suction and discharge pressures daily – especially in systems with multiple pumps – to identify upstream blockages or pressure imbalances that could lead to cavitation and seal damage.

Temperature checks are just as important. Monitor bearing housings for unusual heat levels, and ensure cooling systems for flush fluids show a temperature drop of about 50°F to 100°F (10°C to 38°C) across the cooler. For seal support systems, check reservoir levels weekly and confirm that flush line orifices are clear by measuring temperature changes across them.

William Forsthoffer, author and contributor to Turbomachinery Magazine, highlights the need for a comprehensive monitoring approach:

"Most plant condition monitoring programs do not integrate centrifugal pump performance (operating point and produced head) with mechanical condition (vibration and temperature). Neglecting pump performance… neglects consideration of approximately 80 percent of the potential root causes for mechanical seal failure."

Additionally, alignment checks after thermal cycles are crucial to avoid leaks caused by misalignment.

| Inspection Frequency | Component | Action Item |

|---|---|---|

| Daily | Suction/Discharge | Record pressure and inspect for visible leaks |

| Daily | Motor/Bearings | Listen for unusual noise and check for vibrations |

| Weekly | Seal Support | Verify reservoir levels and flush line circulation |

These routine checks are essential for spotting potential issues early and planning timely replacements or upgrades.

Seal Replacement and Upgrades

Routine inspections are just the beginning. Scheduled replacements are equally important to ensure pump reliability. Maintenance intervals typically range from every 3–6 months or every 3,000–6,000 operating hours, depending on the application. A full overhaul, including dismantling the pump and replacing worn components like seals, wear rings, impellers, and gaskets, is recommended every 1–2 years.

Certain wear tolerances determine when components should be replaced. For example:

- Replace wear rings when clearance exceeds 0.032 inches per side.

- Replace the shaft or sleeve if shaft runout goes beyond 0.002 inches.

- For the casing and impeller, replace them if wear or erosion surpasses a depth of 1/8 inch.

- Change oil and grease bearings every 2,000 operating hours or every 3 months, whichever comes first.

Upgrades can also make a big difference. Consider switching to newer sealing technologies that reduce maintenance needs. For instance, upgrading from traditional packing to mechanical seals or specialized systems can lower stuffing box pressure and extend seal life. To maximize reliability, maintain seal chamber pressure at least 50 psi (345 kPa) above the fluid’s vapor pressure.

Training and Documentation

Physical maintenance is only part of the equation. Proper training plays a huge role in preventing the operational and installation errors that cause most pump failures. Hands-on training for technicians should emphasize the critical impact of proper installation. Misalignment or incorrect lubrication during setup are two of the biggest culprits behind premature seal failures. As SEPCO notes:

"By fully understanding the importance of installation, technicians can help increase the life of the seals and the system."

Operators also need to know how to run pumps within their Best Efficiency Point (BEP). Operating outside this range can lead to recirculation and vibration, which are harmful to mechanical seals. Training should include how to identify signs of off-BEP operation and make necessary adjustments.

Detailed documentation is another cornerstone of preventive maintenance. Keep comprehensive logs of all inspections, repairs, and replacements, noting specific part numbers and the reasons for replacements. Track performance metrics like flow rates, discharge pressure, energy usage, and vibration levels to detect early signs of wear or degradation. Monitoring amperage during startup and comparing it to baseline data can reveal internal friction or impeller fouling before leaks develop. Regularly calibrate sensors for flow, pressure, and vibration to ensure accurate readings. Sharing maintenance reports across departments fosters a unified strategy for pump reliability.

Advanced Leak Prevention Solutions

While regular maintenance and proper sealing methods are the backbone of leak prevention, modern technology has taken protection against pump failures to a whole new level. By combining real-time monitoring, cutting-edge detection techniques, and specialized equipment, these advanced solutions catch problems early – well before they lead to expensive downtime.

Automated systems, in particular, play a key role in identifying and addressing potential issues before they escalate.

Run-Dry Protection and Automated Monitoring

Automated monitoring systems have become a game-changer in preventing mechanical seal failures. These systems continuously track key parameters like vibration, temperature, and pressure to detect abnormalities early. With the extremely small seal gap in pumps, accurate monitoring is critical to avoid leaks.

Run-dry protection is especially important for vertical pumps, where air can get trapped near the seal. Frank Rotello, a Mechanical Seal Reliability Engineer at Cummins-Wagner, explains the risk:

"The mechanical seal will soon fail if the pump continues to run in [a dry] condition".

To counter this, advanced seal support systems monitor fluid levels and automatically shut down pumps when dry-running conditions are detected.

Paul Lesnau, Sales Manager and Field Engineer at Swagelok Northern California, highlights the advantages of centralized monitoring in industrial settings:

"Petrochemical plants with instrumented pumps and centralized monitoring are even better positioned for early identification and remediation of mechanical seal leakage causes".

These systems are also designed to adapt to changing process conditions, such as shifts in viscosity, increased particulate levels, or unexpected temperature spikes, which can push a mechanical seal beyond its operating limits.

Fluorescent Dye Detection Systems

In addition to automated monitoring, fluorescent dye detection provides a simple yet highly effective way to identify leaks visually.

Fluorescent leak detection works by adding a fluorescent dye to the system fluid. During maintenance checks, technicians use a UV-LED lamp to scan the pump exterior, revealing any glowing points where fluid is escaping. This technique can detect leaks as small as 1/8 oz per year, making it an excellent tool for catching minor issues before they grow into major problems.

The process is straightforward: add the dye to the system fluid, let it circulate for 5 to 45 minutes (depending on system size), and inspect the pump with UV light. Different dyes are tailored to specific fluids, such as petroleum oils, synthetic lubricants, water-glycol mixtures, and fuels. The dye can remain in the system indefinitely, allowing for routine inspections without the need for flushing. For larger industrial operations, automated dosing systems can continuously add dye for ongoing real-time monitoring.

Solutions from NOVA Petroleum Services

NOVA Petroleum Services provides advanced sealing technologies and monitoring solutions that integrate seamlessly with modern pump maintenance practices. Their offerings include progressive cavity pumps, plunger pumps, and complete production systems tailored for demanding oilfield applications. Beyond equipment, they offer support for upgrades, replacements, and the transition to newer sealing technologies that reduce maintenance needs and extend pump life. For operators aiming to implement the preventive measures discussed here, NOVA’s expertise and product range deliver a dependable path to improved pump reliability.

Conclusion

Preventing leaks in centrifugal pumps isn’t just about fixing problems when they arise – it’s about having a well-rounded plan that incorporates proper installation, regular maintenance, and modern sealing technologies. With sealing device malfunctions accounting for an eye-opening 69% of centrifugal pump failures, staying ahead of potential issues is critical.

Key practices like ensuring precise alignment (within 0.001"–0.002") and operating pumps at their Best Efficiency Point (BEP) to avoid dry running are foundational for keeping systems running smoothly. Upgrading to advanced mechanical seals and maintaining robust support systems can significantly cut down on fluid loss and maintenance expenses. In fact, a well-maintained seal support system is crucial for ensuring reliable operation.

Using advanced monitoring systems and early detection methods can stop small issues from growing into major, costly failures. Considering that mechanical seal leakage drives more than 50% of pump maintenance needs, investing in preventive strategies can lead to less downtime and better compliance with operational standards.

For those looking to implement these strategies effectively, NOVA Petroleum Services provides a full suite of equipment and expertise. Their offerings – ranging from progressive cavity pumps and plunger pumps to modern seal upgrades – are specifically designed for the rigorous demands of oilfield applications. Whether you’re tackling an urgent leak or planning a full system upgrade, their team can craft solutions tailored to your operational requirements.

FAQs

What are the benefits of using mechanical seals instead of packing seals in centrifugal pumps?

Mechanical seals bring notable benefits when compared to packing seals in centrifugal pumps. One of their standout features is exceptional leakage control, which helps minimize fluid loss while promoting a cleaner and safer workspace. This makes them an excellent choice for maintaining operational efficiency.

Another advantage is their long-lasting performance and reliability, which reduces the wear and tear on pumps over time. Plus, they demand less upkeep, cutting down on maintenance efforts. By reducing friction, mechanical seals also help lower energy use, translating to noticeable cost savings.

These seals shine in high-pressure or hazardous environments, where traditional packing seals might fall short in performance, making them a dependable option for challenging applications.

How do automated monitoring systems help prevent leaks in centrifugal pumps?

Automated monitoring systems are essential for keeping leaks at bay, as they constantly keep an eye on key factors like pressure, temperature, vibration, and seal condition. By spotting unusual patterns early, these systems send out alerts, giving operators the chance to step in and fix problems before they escalate into leaks.

This real-time detection not only helps prevent costly downtime but also trims maintenance expenses and boosts the longevity of centrifugal pumps. It’s a proactive way to ensure operations stay safe and dependable.

What are the best practices to ensure proper alignment of centrifugal pumps and prevent leaks?

Ensuring proper alignment of centrifugal pumps is key to avoiding leaks and keeping performance at its best. Misaligned pumps can lead to uneven stress on seals, faster wear on bearings, and inefficient operation – all of which increase the likelihood of leaks.

Here’s how to maintain alignment effectively:

- Schedule regular alignment checks during routine maintenance or after major operational changes. Use tools like laser alignment systems for precise results.

- Inspect the coupling to confirm bolts are tightened to the manufacturer’s specifications, components show no signs of wear, and alignment tolerances are within acceptable limits (typically ≤0.001 in. offset or 0.05° angular misalignment).

- Keep an eye on vibration and temperature levels as these can be early signs of misalignment. Any unusual readings may indicate the need for realignment.

- Ensure the foundation is stable by checking that the pump base remains level and secure. Shifting foundations can throw off alignment.

By addressing alignment issues quickly and consistently, you can minimize seal leaks and extend your pump’s lifespan. NOVA Petroleum Services offers specialized tools like laser alignment systems and on-site expertise to help you achieve reliable, leak-free operation.