If you’re managing oil wells, choosing the right pumping system is critical. On one side, ESP power optimization uses advanced technology like variable speed drives (VSDs), permanent magnet motors (PMMs), and real-time monitoring to cut energy use and improve performance. On the other, sucker rod pumps (SRPs) and progressive cavity pumps (PCPs) rely on older, fixed-speed designs that struggle with efficiency and require frequent maintenance.

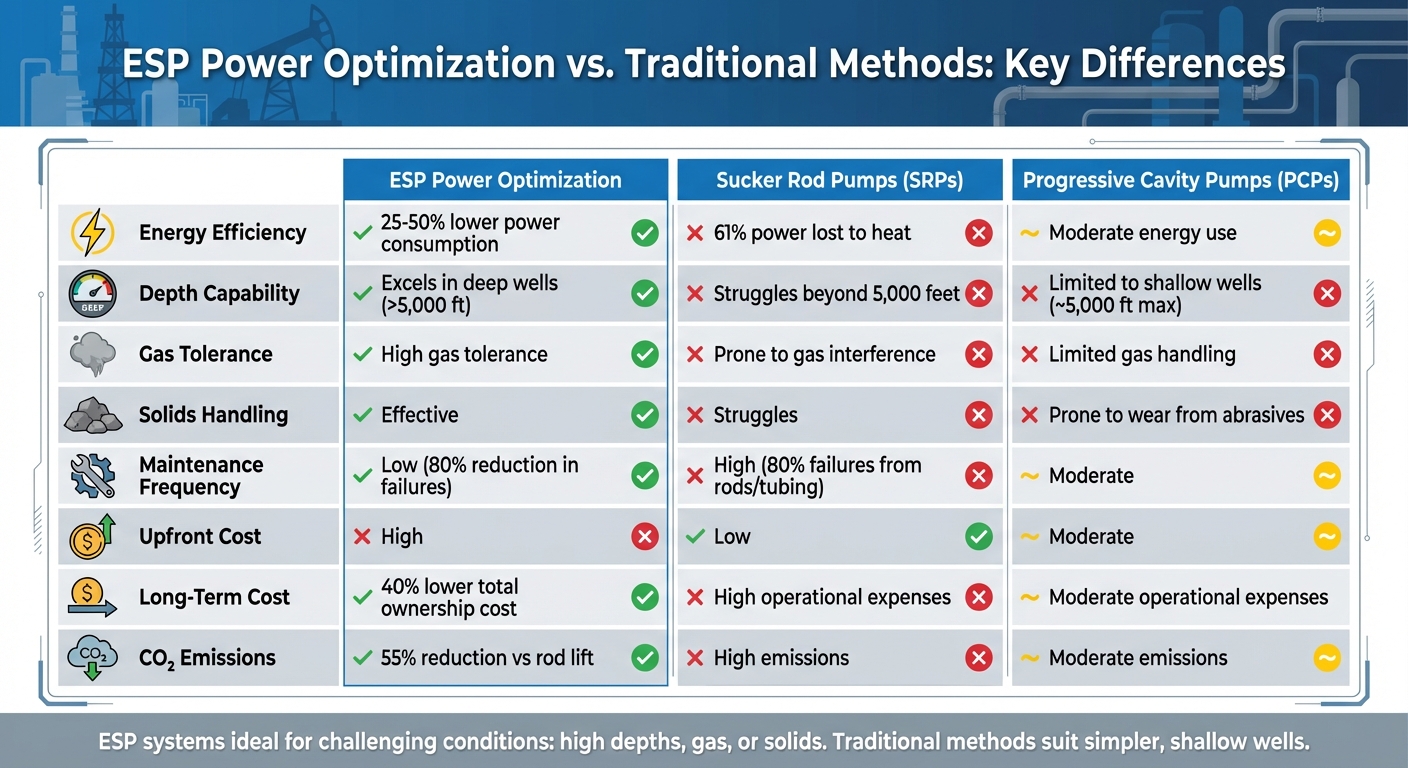

Here’s a quick breakdown of the key differences:

- Energy Efficiency: ESP systems reduce power consumption by 25–50%, while SRPs lose up to 61% of energy as heat.

- Depth Capability: ESPs work well in deep and deviated wells; SRPs often fail beyond 5,000 feet.

- Gas & Solids Tolerance: ESPs handle high gas and solids content better than SRPs and PCPs.

- Maintenance: ESPs eliminate sucker rods, reducing failures by up to 80%, while SRPs face frequent tubing and rod issues.

- Cost: ESPs have higher upfront costs but lower long-term expenses due to reduced energy use and fewer breakdowns.

Quick Comparison

| Factor | ESP Power Optimization | Sucker Rod Pumps (SRPs) | Progressive Cavity Pumps (PCPs) |

|---|---|---|---|

| Energy Efficiency | 25–50% lower power use | High energy loss | Moderate energy use |

| Depth Capability | Excels in deep wells | Struggles beyond 5,000 ft | Limited to shallow wells |

| Gas Tolerance | High gas tolerance | Prone to gas interference | Limited gas handling |

| Solids Handling | Effective | Struggles | Prone to wear from abrasives |

| Maintenance Frequency | Low | High | Moderate |

| Upfront Cost | High | Low | Moderate |

ESP systems are ideal for wells with challenging conditions like high depths, gas, or solids. SRPs and PCPs may suit simpler, shallower wells but come with higher maintenance demands and energy costs.

ESP Power Optimization vs Traditional Pumping Methods Comparison

Production Optimization of Oilfields with ESP-Lifted Wells

How ESP Power Optimization Works

ESP systems rely on multistage centrifugal pumps, which use impellers to increase the kinetic energy of fluids and diffusers to convert that energy into pressure. These components are often made from high-nickel alloy, chosen for its ability to resist abrasion and corrosion. Since the casing diameters are limited, multiple pump stages are stacked to achieve the necessary production pressure. This mechanical arrangement lays the groundwork for advanced optimization techniques.

Core Technologies in ESP Optimization

Modern ESP systems leverage three primary technologies to enhance performance. Permanent magnet motors (PMMs) deliver consistent torque across a wide range of speeds, eliminating the need for gear reducers. This not only reduces power consumption but also cuts down on CO₂ emissions. Variable speed drives (VSDs) play a crucial role by adjusting motor frequency in real time to match changing downhole conditions. This ensures continuous control over flow and pressure, improving productivity and extending equipment lifespan by minimizing voltage stress during startups. Lastly, downhole sensors monitor key parameters – such as intake and discharge pressures, temperatures, vibration, current leakage, and flow rates – and relay this information to the surface through telemetry systems.

Additional innovations, like hollow rotors and high-temperature elastomers, help reduce weight and vibration while expanding the system’s operating range. Together, these advancements unlock significant real-time operational advantages.

Benefits of Real-Time Monitoring

Real-time monitoring provides the ability to make predictive adjustments and perform maintenance without halting operations. Data from downhole sensors is continuously fed into SCADA systems, enabling operators to remotely fine-tune motor speed and system voltage. This capability helps prevent common issues such as pump-off conditions, gas lock, and overheating. By identifying potential problems days or even weeks in advance, operators can mobilize resources proactively, reducing stress on motors and keeping winding temperatures lower, which extends insulation life.

When compared to traditional fixed-speed systems, real-time monitoring offers a more reliable approach to maintaining peak efficiency. Automated analysis of operational data ensures the pump consistently performs at its best, giving operators greater confidence in their optimization strategies.

Traditional Pumping Methods: Mechanics and Limitations

How Sucker Rod Pumps and Progressive Cavity Pumps Operate

Sucker rod pumps (SRPs), also called beam pumps or rod pumps, are the go-to choice for artificial lift systems, operating in about two-thirds of oil wells globally. These pumps use a surface power system – typically a beam and crank setup – to create a reciprocating motion. This motion travels downhole via a sucker-rod string, which connects to a plunger and valve assembly. The result? A positive displacement mechanism that pushes fluid to the surface.

Progressive cavity pumps (PCPs), on the other hand, work differently. They consist of a helical rotor spinning inside a matching helical stator. As the rotor turns, it creates a series of negative-pressure cavities that move fluid upward through the pump. This design is particularly effective for handling high-viscosity crude oil.

However, both systems operate at fixed speeds, which limits their ability to adapt to changing downhole conditions. These mechanical designs, while functional, reveal clear shortcomings when faced with today’s complex production demands.

Challenges with Traditional Methods

Both SRPs and PCPs come with notable challenges. Sucker rod pumps, for instance, struggle in deeper wells due to the increased power needed to lift heavier discharge columns. Variations in well pressure – whether overbalanced or underbalanced – can spike gearbox loads by 40%–60%. Failures are also a major issue: up to 80% of rod lift system breakdowns stem from tubing holes or parted rods, often requiring expensive and time-consuming workovers. Gas locking is another headache; when gas enters the pump, it prevents the pressure needed to open valves, leading to little or no fluid production.

Progressive cavity pumps face their own set of issues. They’re generally limited to well depths of around 5,000 feet and aren’t well-suited for deviated wells. Abrasive materials can quickly wear down their helical components, reducing their operational lifespan. Additionally, neither SRPs nor PCPs offer real-time monitoring, making it tough to identify problems early or adjust performance as reservoir conditions shift. PCPs also lack dynamic speed control, which forces operators to stick to predefined guidelines instead of making real-time adjustments. This rigidity is especially problematic in wells with high solids content or significant gas volumes – environments where traditional systems struggle to operate efficiently.

Direct Comparison: ESP Power Optimization vs. Traditional Methods

Efficiency, Power Usage, and Performance Metrics

When it comes to efficiency and performance, ESP power optimization clearly surpasses traditional methods. Systems equipped with Permanent Magnet Motors (PMMs) and Variable Speed Drives (VSDs) bring measurable improvements across multiple metrics.

Traditional ESP systems lose a staggering 61% of power to heat, leaving only 39% for hydrocarbon production. In contrast, PowerSave high-efficiency ESP systems flip this equation, cutting power consumption by at least 25% compared to other modern systems and up to 50% when compared to older, less efficient ones. The Reda PowerEdge ESPCP system takes this even further, slashing power usage and associated CO₂ emissions by up to 55% compared to rod lift systems.

Optimized ESPs also shine in more challenging well environments. They handle deep and deviated wells with ease, manage high gas volume fractions (GVF), and perform reliably in wells with high solids content – areas where traditional sucker rod pumps and progressive cavity pumps often falter. Additionally, the integration of VSDs enables real-time adjustments, ensuring smoother operation and reducing mechanical wear and tear. This boost in efficiency not only lowers operational costs but also enhances reliability.

| Performance Factor | ESP Power Optimization | Traditional Methods |

|---|---|---|

| Energy Efficiency | 25%–50% lower power consumption | 61% of power lost to heat |

| Depth Capability | Excels in deep wells | Often less effective in deep wells |

| Gas Tolerance | Performs well under high GVF conditions | Typically affected by gas interference |

| Solids Handling | Handles high solids content effectively | Struggles in high solids environments |

| Speed Control | Variable speed with VSDs | Fixed-speed operation |

| Deviated Wells | Optimized for deviated applications | Less suited for deviated wells |

Cost Analysis and Operational Flexibility

The economic advantages of optimized ESP systems go well beyond energy savings. For instance, the Reda PowerEdge ESPCP system reduces total ownership costs by up to 40% by eliminating sucker rods. This is a game-changer, as sucker rods are a major source of failures – up to 80% of rod lift system breakdowns stem from issues like tubing holes and parted rods, which often lead to costly workovers and production downtime.

Maintenance becomes far simpler with optimized ESP systems. PMMs eliminate mechanical gear reducers, a common failure point in traditional setups. Additionally, lower heat and vibration levels extend equipment life and reduce the frequency of unplanned interventions. VSDs add another layer of value by ensuring smoother operations and minimizing mechanical stress on key components.

Another standout feature of optimized ESP systems is their operational flexibility. Unlike traditional pumps that run at a fixed speed, these systems can dynamically adapt to changes in well pressure, fluid composition, and production rates. This adaptability boosts production efficiency and helps extend the well’s economic lifespan.

sbb-itb-325a090

Benefits and Trade-offs of ESP Power Optimization

Benefits of ESP Power Optimization

Optimizing ESP power usage can lead to major improvements in how efficiently operations run. For starters, these systems are designed to cut down on power consumption, which translates into lower electricity bills and a smaller carbon footprint. Plus, with the help of downhole sensors, adjustments can be made remotely, meaning fewer workovers are needed. This access to real-time data enables precise tweaks, reducing both downtime and the frequency of maintenance.

Maintenance costs also take a dive with optimized ESP systems. By doing away with sucker rods and relying less on mechanical gear reducers – both common culprits for system failures – operators can avoid costly workovers and production halts. The reduced heat and vibration in these systems also prolong the lifespan of components, cutting down on unplanned repairs and overall maintenance expenses.

Another standout feature is operational flexibility. Unlike traditional pumps that run at fixed speeds, optimized ESP systems can adjust dynamically to changes in reservoir pressure, fluid composition, and production rates. This ability to adapt is especially useful in mature wells, where maintaining a wide operational range can keep production economically viable for longer periods. While these advantages are clear, it’s important to weigh them against the associated trade-offs.

Trade-offs and Limitations

Despite the benefits, there are some trade-offs to consider with ESP power optimization. The initial investment is typically higher than traditional systems. This includes not just the cost of the equipment but also the infrastructure needed for real-time monitoring and control. That said, these upfront costs are often balanced out by lower operational expenses and the extended lifespan of the equipment.

Optimized ESP systems also have their limitations when it comes to certain well conditions. For instance, high gas fractions – generally above 10% at the pump intake – can disrupt their performance. Similarly, wells with high levels of solids, like sand, can cause faster wear on pump components. Extreme temperatures and corrosive fluids present additional challenges, requiring careful system selection and setup. Lastly, the complexity of ESP assemblies means that a failure in one component can lead to a chain reaction of issues, potentially causing longer downtimes for repairs. To minimize these risks, effective system design, regular monitoring, and proactive maintenance are crucial.

Applications and Case Studies

Measured Performance Improvements

Field results reveal notable advancements in efficiency. For instance, the Reda PowerEdge ESPCP system has been shown to cut power consumption by up to 55% compared to traditional rod lift systems. This reduction directly translates to a 55% decrease in CO₂ emissions as well.

By eliminating sucker rods, operators can lower the total cost of ownership by up to 40%. A real-world example from the Caño Limon field demonstrates how enhanced motor technology in ESP systems reduced failure rates by 50%, leading to better uptime and uninterrupted production.

Comparison to Traditional Methods in Practice

These performance improvements highlight why optimized ESP systems outperform older technologies in practical applications. Unlike fixed-speed traditional pumps, which struggle to adapt to varying reservoir conditions, optimized ESP systems are designed for flexibility and efficiency in dynamic environments.

Traditional rod lift systems often face challenges like excessive energy consumption and frequent mechanical failures caused by sucker rod wear. In wells with fluctuating production rates or changing reservoir conditions, fixed-speed pumps fall short, as they lack the ability to adjust to these variations effectively.

Optimized ESP systems overcome these challenges with real-time monitoring and dynamic adjustments. Instead of relying on scheduled interventions or manual tweaks, operators can make immediate changes to match downhole conditions. This capability is especially crucial in mature fields, where maintaining economic production depends on precise control of pumping parameters. The option to remotely adjust motor speed and pump performance minimizes production losses typically associated with conventional systems. These advantages explain why many operators in mature fields are increasingly turning to optimized ESP systems for reliable and efficient operations.

Conclusion: Choosing the Right Pumping Solution

When deciding between ESP power optimization and traditional pumping methods, it’s essential to align your choice with the specific needs of your well and your operational objectives.

Start by assessing your well’s unique characteristics. ESPs perform exceptionally well in conditions like low bottomhole pressure, high water cut, and greater depths. They are also versatile, working effectively in vertical, deviated, and horizontal wells. For wells handling high volumes, corrosive fluids, or abrasive materials, specialized ESP designs are built to handle these challenges. On the other hand, ESPCP systems are a solid choice for mature wells with lower flow rates.

Cost considerations are equally important. Energy consumption and operational flexibility play a big role here. As mentioned earlier, real-time monitoring and Variable Speed Drives (VSDs) enhance ESP performance by providing continuous flow and pressure adjustments in response to changing reservoir conditions.

Think about the bigger picture when evaluating total ownership costs. While ESPs may have higher initial costs, they often result in long-term savings by reducing maintenance needs, minimizing workovers, and cutting energy expenses. The absence of failure-prone components, like sucker rods, further contributes to their reliability and cost-effectiveness.

For wells with unique challenges, intermittent operation can help high-flowrate ESPs achieve near-optimal efficiency. When choosing a system, take into account your production goals, maintenance capabilities, and budget. Ultimately, the right solution will depend on how well it aligns with the performance, cost, and adaptability factors discussed above.

FAQs

What are the key advantages of ESP power optimization compared to traditional pumping methods?

Electric Submersible Pump (ESP) power optimization brings a host of advantages compared to traditional pumping techniques. By increasing energy efficiency and cutting down on power usage, it not only trims operating expenses but also extends the productive lifespan of wells – especially those dealing with high water output.

Another key benefit is improved lift performance, thanks to variable-speed control. This technology adjusts seamlessly to shifts in well conditions, ensuring smoother operations. On top of that, it minimizes the need for frequent maintenance, leading to less downtime and greater reliability overall.

How does real-time monitoring improve ESP system performance?

Real-time monitoring transforms an ESP system into a more responsive and effective tool by offering continuous updates on its performance. Using downhole sensors, data like temperature (°F), pressure, motor current, and flow rate is gathered and sent to surface control systems. This enables operators to fine-tune pump speed or voltage with precision, keeping the ESP running at its best. The result? Lower energy use – whether from electricity or diesel generators – and better control over motor temperatures.

But the benefits don’t stop at energy efficiency. Real-time monitoring also plays a key role in preventing unexpected breakdowns. By catching early warning signs, such as unusual temperature increases or surging current, operators can address potential issues before they escalate. This approach not only extends the equipment’s lifespan but also reduces downtime and keeps production steady. For clients of NOVA Petroleum Services / Atokan Drilling Technologies, adding these monitoring tools to their setups is a practical way to improve efficiency, cut costs, and ensure dependable operations for both onshore and offshore projects in the U.S.

What should I consider when deciding between ESP and traditional pumping methods for my well?

When deciding between electric submersible pumps (ESPs) and traditional pumping systems like rod-lift or positive-displacement pumps, it’s essential to weigh a few key factors. Reservoir conditions play a big role – things like bottom-hole pressure and gas-to-oil ratio (GOR) can tip the scale. ESPs shine in wells with low pressure and a low to moderate GOR, while high-GOR wells might be better suited for traditional methods. The type of fluid matters too. ESPs are great for handling high water-cut or low-API-gravity fluids, but wells with high gas content, solids, or extreme temperature swings might demand a different approach.

Operational requirements also influence the decision. Factors like production rate, power availability, and energy efficiency come into play. ESPs work well for high-production wells in areas with steady electricity, while traditional pumps are often better for remote locations with limited infrastructure. Maintenance is another piece of the puzzle. While ESPs are becoming easier to maintain, they still need careful design and monitoring to prevent issues.

For operators in the U.S., NOVA Petroleum Services offers a variety of ESPs and traditional pumping systems. They also provide expert engineering support to help you find the best match for your well’s unique conditions. By examining reservoir characteristics, fluid properties, and operational needs, you can choose the solution that boosts production and efficiency.