When it comes to heat exchangers in oilfield environments, corrosion is a major challenge. Factors like CO₂, H₂S, chlorides, and high temperatures can drastically reduce equipment lifespan, leading to frequent failures and costly replacements. However, choosing the right materials can extend service life from just a few years to over two decades, significantly cutting maintenance costs and improving operational reliability.

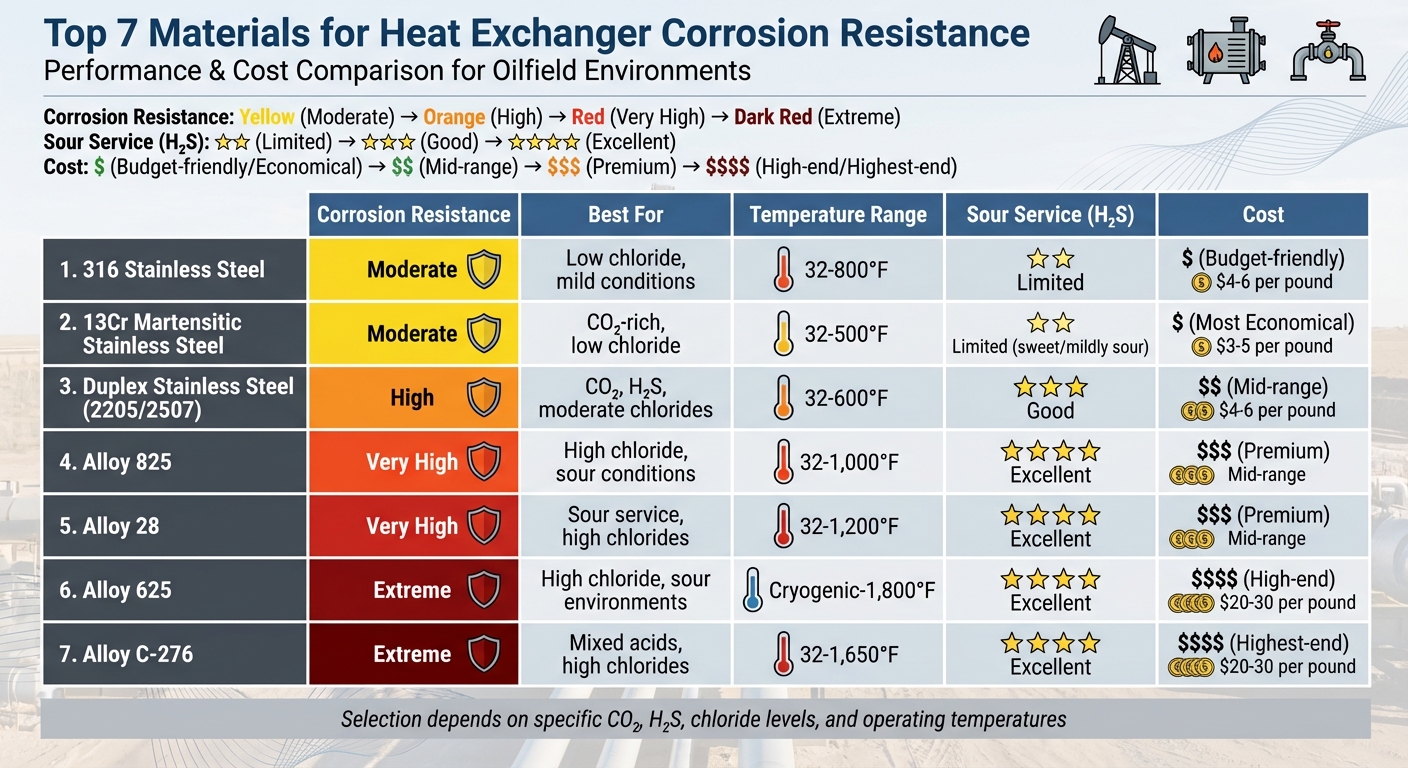

Here’s a quick rundown of the top materials for corrosion resistance:

- Duplex Stainless Steel (e.g., 2205, 2507): High strength and excellent resistance to CO₂, H₂S, and chlorides. Cost: $4–6 per pound.

- 316 Stainless Steel: Affordable option for moderate conditions but struggles with high chloride or H₂S exposure. Cost: $4–6 per pound.

- Alloy 625: Outstanding for extreme environments with high chloride and H₂S. Cost: $20–30 per pound.

- 13Cr Martensitic Stainless Steel: Suitable for CO₂-rich systems but limited in chloride-heavy or sour conditions. Cost: $3–5 per pound.

- Alloy 825: Handles high chloride and sour environments well, offering a balance between performance and cost. Cost: Mid-range.

- Alloy 28: Strong against sour service and high-chloride exposure, bridging the gap between stainless steels and high-end nickel alloys. Cost: Mid-range.

- Alloy C-276: Best for the toughest conditions, including mixed acids and high chlorides. Cost: $20–30 per pound.

Quick Comparison

| Material | Corrosion Resistance | Best For | Cost |

|---|---|---|---|

| Duplex Stainless Steel | High | CO₂, H₂S, moderate chlorides | $4–6 per pound |

| 316 Stainless Steel | Moderate | Low chloride, mild conditions | $4–6 per pound |

| Alloy 625 | Extreme | High chloride, sour environments | $20–30 per pound |

| 13Cr Stainless Steel | Moderate | CO₂-rich, low chloride | $3–5 per pound |

| Alloy 825 | Very High | High chloride, sour conditions | Mid-range |

| Alloy 28 | Very High | Sour service, high chlorides | Mid-range |

| Alloy C-276 | Extreme | Mixed acids, high chlorides | $20–30 per pound |

Selecting the right material depends on your environment’s specific challenges, including the presence of CO₂, H₂S, chlorides, and operating temperatures. Investing in corrosion-resistant alloys can dramatically reduce downtime and maintenance costs, ensuring long-term reliability.

Heat Exchanger Materials Comparison: Corrosion Resistance, Temperature Limits, and Cost

1. Duplex Stainless Steel

Corrosion Resistance in CO₂, H₂S, and Chlorides

Duplex stainless steel, particularly grades like Duplex 2205 and Duplex 2507, is known for its strong resistance to CO₂, H₂S, and chloride environments. Thanks to its austenitic-ferritic microstructure, which includes 22–25% chromium, 3–4% molybdenum, and nitrogen, it forms a passive protective layer. This layer helps limit sweet corrosion in environments with up to 10–15% CO₂, keeping corrosion rates below 0.1 mm/year in standard oilfield brines. For environments containing H₂S, the steel needs to maintain a hardness of less than 28 HRC, allowing it to resist H₂S concentrations up to 10 psi. In chloride-rich waters exceeding 20,000 ppm, Duplex 2507 stands out with a PREN (Pitting Resistance Equivalent Number) above 40 and critical pitting temperatures between 104–140°F in 3–6% NaCl solutions. A noteworthy example is a North Sea case study where Duplex 2507 heat exchangers performed for over 15 years under combined CO₂, H₂S, and chloride exposure, while 316L stainless steel units failed after just 3 years. These properties make duplex stainless steel a dependable option for challenging oilfield conditions.

Temperature Limits

This material operates effectively from cryogenic temperatures up to 480–570°F (250–300°C) under continuous use, withstanding brief exposures up to 840°F (450°C). However, in oilfield heat exchangers, it is typically kept below 300°F (150°C) to prevent embrittlement and the formation of the sigma phase. This thermal stability adds to its reliability in high-pressure oilfield systems.

Suitability for Oilfield Applications

Duplex stainless steel combines high strength – yield strengths over 450 MPa – with toughness and excellent corrosion resistance, making it ideal for high-pressure oilfield environments. Its strength and corrosion resistance are further enhanced by proper welding techniques. For instance, Duplex 2205 is widely used in North Sea oil production for gas coolers exposed to CO₂, H₂S, and chloride mixtures, helping to minimize downtime in demanding applications. Successful welding involves using matching fillers like ER2209, controlling heat input between 0.8–2 kJ/mm, and performing solution annealing at 1,870–2,010°F (1,020–1,100°C), followed by water quenching. This process ensures an optimal ferrite balance of 40–60%, enhancing its performance.

Cost-Effectiveness

In addition to its technical advantages, duplex stainless steel is economically appealing. Priced at $4–6 per pound – roughly 1.5 to 2 times the cost of 316L stainless steel – it offers a more affordable alternative to superalloys. Its high strength allows for thinner tubing, reducing both material usage and overall weight. Moreover, its extended service life and reduced maintenance needs translate into significant life-cycle savings, making it a cost-efficient choice for addressing moderate corrosion challenges.

2. 316 Stainless Steel

Corrosion Resistance in CO₂, H₂S, and Chlorides

316 stainless steel, composed of 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, is a trusted choice for many oilfield heat exchangers due to its corrosion resistance. Its chromium content forms a protective oxide layer, making it effective against CO₂-induced sweet corrosion at low to moderate temperatures and pressures. The inclusion of molybdenum, which sets it apart from 304 stainless steel, improves its resistance to chloride environments by increasing its Pitting Resistance Equivalent Number (PREN) to 24–26. This makes it suitable for chloride concentrations of up to 500–1,000 ppm at temperatures below 140°F (60°C). For instance, Gulf of Mexico platforms have successfully used 316L tube exchangers in CO₂-saturated brines with 500 ppm chlorides at 250°F (120°C) for 15 years. However, in environments with high H₂S levels (partial pressures exceeding 0.05%), 316 stainless steel is prone to sulfide stress cracking. In such cases, compliance with NACE MR0175/ISO 15156 standards is required, limiting its use in sour service. Proper temperature management is key to maintaining its resistance characteristics.

Temperature Limits

In chloride-containing fluids, 316 stainless steel should not be used at temperatures above 140°F (60°C) to avoid chloride stress corrosion. For welded components, the low-carbon variant, 316L, is preferred as it reduces the risk of sensitization and intergranular corrosion in heat-affected zones during thermal cycling. This makes 316L the go-to material for tube-side applications where temperatures remain within safe operating limits. Adhering to these temperature guidelines ensures the material’s reliability in oilfield heat exchanger designs.

Suitability for Oilfield Applications

316 stainless steel is a cost-effective solution for less demanding conditions, making it a popular choice for shell-and-tube heat exchangers in low-to-moderate corrosion environments. It is commonly used in applications such as cooling produced water, gas dehydration units, and crude oil preheaters, where chloride levels remain below 1,000 ppm and H₂S concentrations are minimal. To balance cost and corrosion resistance, manufacturers often use 316L on the tube side and 304L on the shell side. Proper welding techniques, such as GTAW or SMAW with low heat input, along with post-weld annealing, are essential for optimal performance. Routine inspections using dye penetrant or ultrasonic testing, combined with effective water chemistry management – like controlling chloride levels, using oxygen scavengers, and applying biocides – can extend the service life of these systems to up to 20 years, particularly in offshore platforms and upstream processing facilities.

Cost-Effectiveness

With a price range of $4–6 per pound, 316 stainless steel is 30–50% cheaper than Duplex 2205 ($8–10 per pound) and significantly less expensive than Alloy 625 ($20–30 per pound). This affordability makes it a practical choice for moderate corrosion conditions, where extreme resistance isn’t necessary. Its lower material and fabrication costs enable widespread use in oilfield heat exchangers, offering long-term savings by minimizing downtime in less aggressive environments. For operations with moderate chloride levels and temperatures kept below 140°F (60°C), 316 stainless steel strikes an excellent balance between performance and cost, earning its reputation as the industry-standard material before turning to more expensive duplex or nickel-based alloys for harsher conditions.

3. Alloy 625

Corrosion Resistance in CO₂, H₂S, and Chlorides

Alloy 625 stands out as a robust option for extreme environments, offering superior resistance compared to stainless and duplex alloys. This nickel-based superalloy typically contains 58% nickel, 20–23% chromium, 8–10% molybdenum, and 3–4% niobium. Its high nickel content provides exceptional protection against chloride-induced stress corrosion cracking, a common problem in seawater and produced-water heat exchangers. The combination of chromium and molybdenum enhances its ability to withstand both oxidizing and reducing conditions, while molybdenum and niobium work together to minimize pitting and crevice corrosion in high-chloride brines. This makes Alloy 625 highly effective in mixed CO₂/H₂S/chloride environments, outperforming 316L stainless steel and many duplex grades. When used within the guidelines of NACE MR0175/ISO 15156 standards, it also demonstrates excellent resistance to sulfide stress cracking, reducing corrosion allowances and extending the lifespan of equipment. Its corrosion resistance makes it a reliable choice for demanding applications across a wide temperature range.

Temperature Limits

One of Alloy 625’s key strengths is its ability to perform reliably across a broad temperature spectrum. It can handle conditions from cryogenic temperatures to approximately 1,800°F (982°C), making it suitable for high-pressure, high-temperature heat exchangers. However, in oilfield and seawater applications – where corrosion, scaling, and fouling are significant concerns – the practical temperature range is typically between 400–600°F (204–316°C). Engineers should consult datasheets and account for thermal expansion to prevent thermal fatigue in these scenarios. This wide temperature capability ensures dependable operation even under the fluctuating thermal conditions common in oilfield environments.

Suitability for Oilfield Applications

Alloy 625 is a go-to material for seawater-cooled shell-and-tube heat exchangers used in refineries, offshore topsides, and power plants. Its resistance to the combined effects of saltwater, CO₂, and H₂S makes it particularly valuable in production and process systems that handle sour hydrocarbons and produced water. Applications include gas-cooler exchangers, condensers, and reboiler coils. It’s also widely used in petrochemical and chemical plants, where exchangers are exposed to harsh acidic and chloride-rich environments. Companies like NOVA Petroleum Services and Atokan Drilling Technologies Inc often source Alloy 625 components, such as nickel-alloy tubulars, for production and equipment upgrades. Maintaining its corrosion resistance in heat-affected zones requires proper welding techniques and post-weld heat treatment. With its ability to balance technical performance and operational demands, Alloy 625 is a preferred choice for challenging environments.

Cost-Effectiveness

At $20–30 per pound, Alloy 625 is significantly more expensive than 316 stainless steel, which costs $2–4 per pound. However, its higher upfront cost is often offset by better lifecycle economics in aggressive environments involving CO₂, H₂S, and chlorides. It reduces unplanned downtime, lowers the need for additional corrosion allowances, and extends replacement intervals. Positioned in the middle-to-upper tier of corrosion-resistant materials, Alloy 625 offers more durability than stainless and duplex grades while being more affordable and easier to handle than materials like Hastelloy C-276 or titanium. For less aggressive conditions with low chloride levels and minimal H₂S, options like 316L or duplex stainless steel may be more cost-effective. In extremely severe environments, higher-cost alloys might be justified due to their extended service life. To ensure Alloy 625 delivers long-term savings, a thorough corrosion analysis is critical before making a selection.

4. 13Cr Martensitic Stainless Steel

Corrosion Resistance in CO₂, H₂S, and Chlorides

13Cr Martensitic Stainless Steel, with its 13% chromium content, low carbon levels (0.01–0.03%), and small amounts of nickel and molybdenum, is designed to form a protective chromium oxide layer. This makes it a reliable choice for CO₂ "sweet service." It handles CO₂ corrosion effectively at partial pressures up to 10–20 bar and temperatures around 150°C (302°F). For instance, a North Sea field study showed that 13Cr tubing used in CO₂ heat exchangers lasted over a decade with corrosion rates under 0.1 mm/year at 120°C and 100 bar CO₂ pressure – outperforming carbon steel by a factor of five. However, its performance diminishes in sour service. The material provides moderate resistance to H₂S in low concentrations (up to 20% H₂S as per NACE MR0175 standards) but struggles against chlorides. Risks of pitting and stress corrosion cracking rise significantly when chloride levels exceed 50 ppm Cl⁻, especially at higher temperatures. In high-H₂S environments, failure rates increased by about 20% without the use of chemical inhibitors. These characteristics make 13Cr ideal for CO₂-rich systems but highlight its limitations in harsher, sour conditions.

Temperature Limits

The material performs best in CO₂ environments at temperatures below 150°C (300°F). In systems containing chlorides, temperatures should be kept under 93°C (200°F) to avoid stress corrosion cracking. When temperatures exceed these limits, the protective chromium oxide layer destabilizes, leading to rapid corrosion. Although 13Cr can technically endure temperatures up to 232°C (450°F) in air, these thresholds are critical for practical applications, particularly in oilfield settings.

Suitability for Oilfield Applications

With a yield strength exceeding 550 MPa and a cost-effective corrosion resistance profile, 13Cr is a solid choice for downhole tubing, wellhead equipment, and heat exchangers in CO₂-dominated production systems. It has seen widespread use in oilfields like the North Sea and Gulf of Mexico, especially in subsea heat exchangers processing fluids with moderate souring. The material excels in tube-side applications for CO₂-rich streams, though components exposed to chlorides – such as exchanger shells – often require cladding for added protection. Companies like NOVA Petroleum Services frequently source 13Cr components for production equipment upgrades. For optimal performance, low-carbon grades like L80 or T95 (API 5CT) are recommended, along with preheating (100–200°C) and post-weld heat treatment (600–650°C) to maintain toughness.

Cost-Effectiveness

One of 13Cr’s biggest advantages is its affordability. Priced at $3–5 per pound, it delivers strong performance with high strength, allowing for thinner walls and reduced lifecycle costs in CO₂-dominated operations. It is significantly cheaper than premium nickel alloys. However, in more aggressive environments with unexpected chloride levels, maintenance costs may rise compared to duplex or nickel alloys. This underscores the importance of conducting a detailed environmental analysis before selecting materials for a project.

5. Alloy 825

Corrosion Resistance in CO₂, H₂S, and Chlorides

Alloy 825 is a nickel–iron–chromium alloy with added molybdenum, copper, and titanium, designed to thrive in harsh environments containing CO₂, H₂S, and chlorides. With a nickel content ranging from 38–46%, it stands out for its ability to resist chloride stress corrosion cracking, outperforming 316 stainless steel in high-temperature, high-chloride conditions. Its composition is carefully balanced: chromium and molybdenum enhance its defense against pitting and crevice corrosion, while copper and titanium improve its performance in acidic and H₂S-rich environments. In sour service, Alloy 825 is qualified for moderate to high H₂S partial pressures and can tolerate chloride concentrations in the tens of thousands of parts per million – well beyond the limits of 316L – making it a reliable choice for tubing and shell components exposed to high-chloride produced water.

Temperature Limits

Alloy 825 is not just corrosion-resistant; it also performs across a wide temperature range. It operates effectively from cryogenic levels up to 538°C (1,000°F). In oilfield applications, where aqueous corrosion is a concern, its typical range is from ambient temperatures up to 280–300°C (536–572°F). The alloy’s titanium stabilization ensures resistance to intergranular corrosion during thermal cycling, making it particularly suitable for low-to-medium temperature conditions, such as those found in heat exchangers.

Suitability for Oilfield Applications

This alloy’s thermal and corrosion resistance makes it a dependable choice for oilfield environments. Its balanced composition is ideal for heat exchangers operating in corrosive brines and sour fluids. Common applications include produced water coolers, gas dehydration units, and acid gas/amine system exchangers. By minimizing corrosion allowances and reducing the risk of leaks, Alloy 825 helps maintain consistent operations, even in demanding conditions. For instance, it shows lower corrosion allowance consumption and reduces the likelihood of leaks at tube-to-tubesheet joints in aggressive environments. In the U.S. oil and gas industry, companies like NOVA Petroleum Services integrate Alloy 825 into production systems to cut down on downtime and replacement frequency. To maintain its corrosion resistance in sour and chloride-rich conditions, proper fabrication practices are essential. This includes using qualified filler metals to prevent weld sensitization and designing tube-to-tubesheet joints to limit crevices and residual stresses.

Cost-Effectiveness

While Alloy 825 is more expensive than 316L stainless steel due to its higher nickel content, it remains more affordable than premium alloys like C-276 or titanium. Its upfront cost is offset by long-term savings, thanks to thinner corrosion allowances, extended service life, and fewer unplanned shutdowns. For sour, high-chloride applications, U.S. engineers often weigh the total installed cost alongside 10–20 years of operating and maintenance expenses. Given that downtime can cost tens or even hundreds of thousands of dollars per day, Alloy 825 often strikes the right balance between upfront investment and long-term corrosion resistance.

sbb-itb-325a090

6. Alloy 28

Corrosion Resistance in CO₂, H₂S, and Chlorides

Alloy 28 (UNS N08028) is a high-alloy austenitic stainless steel developed specifically for challenging sour oil and gas environments that contain CO₂, H₂S, and chlorides. Its composition – 27% chromium, 31% nickel, 3–4% molybdenum, and 1% copper – is designed to provide robust protection against corrosion. The high chromium content helps form a stable oxide layer that resists general corrosion and pitting, while the nickel content ensures an austenitic structure that reduces the risk of stress corrosion cracking in fluids containing H₂S. With a Pitting Resistance Equivalent Number (PREN) over 40, Alloy 28 significantly outperforms 316 stainless steel in environments with brine concentrations as high as 100,000 ppm chlorides.

Laboratory tests simulating harsh conditions – such as 100,000 ppm chloride brines saturated with CO₂ at 200°F (93°C) and pH 4 – showed Alloy 28 had a uniform corrosion rate of less than 0.1 mm/year. Field data from North Sea oil platforms further reinforced its reliability, with corrosion rates reported at less than 0.05 mm/year over five years. This performance makes Alloy 28 a dependable choice for sour service heat exchangers.

Temperature Limits

Alloy 28 can operate across a wide temperature range, from cryogenic levels up to 1,000°F (538°C) for continuous use and up to 1,200°F (649°C) intermittently. In oilfield applications, such as heat exchangers handling hot fluids containing CO₂ and H₂S, it is typically used at temperatures up to 400°F (204°C) to prevent sigma phase embrittlement. This temperature flexibility makes it well-suited for applications like produced water coolers, gas processing units, and acid gas treatment systems, where thermal cycling and corrosive conditions are common.

Suitability for Oilfield Applications

In the U.S. oil and gas sector, Alloy 28 has become a trusted material for high-pressure, high-temperature (HPHT) sour wells, acid gas injection systems, and produced-water reinjection. It fills the performance gap between standard stainless steels and high-end nickel alloys, often appearing in material selection diagrams as a step above 13Cr and duplex grades but below premium alloys like C-276. Approved by NACE standards for sour service environments with H₂S partial pressures up to 20%, Alloy 28 is frequently used in heat exchanger tubes, tubesheets, and piping for downhole injection systems and offshore platform exchangers . Companies like NOVA Petroleum Services incorporate Alloy 28 into systems to simplify material selection, ensuring effective corrosion control in both sweet and sour conditions.

Cost-Effectiveness

While offering mid-to-high corrosion resistance, Alloy 28 is 20–50% less expensive per pound than premium nickel alloys due to its lower nickel content. Although its initial cost is higher than 316 stainless steel, the long-term savings from reduced maintenance and extended service life often justify the investment. Many projects see a return on investment within 2–3 years through fewer replacements and decreased downtime. For U.S. engineers assessing total installed costs and 10–20 years of operating expenses, Alloy 28 often stands out as the most practical option for moderate sour service, where fully nickel-based alloys may be unnecessarily expensive .

7. Alloy C-276

Corrosion Resistance in CO₂, H₂S, and Chlorides

Alloy C-276, also known as Hastelloy C-276, is a nickel-molybdenum-chromium superalloy with tungsten that excels in combating the toughest oilfield corrosion challenges. Its composition – approximately 57% nickel, 16% molybdenum, 15.5% chromium, and 4% tungsten – offers robust defense against uniform corrosion, pitting, and crevice attack in environments rich in chlorides, sour gas (H₂S), and CO₂. The high levels of molybdenum and tungsten specifically target localized chloride attack, while the nickel base ensures stability in both oxidizing and reducing conditions. This makes Alloy C-276 particularly effective in handling wet H₂S/CO₂ service, acidizing fluids, and chloride-laden produced water, significantly lowering the risk of stress corrosion cracking compared to standard stainless steels.

That said, it’s worth noting that highly oxidizing environments, such as those containing strong acids like hot, concentrated nitric acid or high levels of ferric or cupric ions, can still pose challenges. For these complex mixed-acid chemistries, a thorough metallurgy review and laboratory testing are recommended.

Temperature Limits

Beyond its corrosion resistance, Alloy C-276 also stands out for its thermal capabilities. It can function in a wide temperature range, from near-cryogenic levels up to approximately 1,500–1,650°F (815–900°C), depending on the medium and pressure. In oilfield applications, it’s commonly used in heat exchangers for tubing and plates exposed to hot produced water, amine solutions, and acidizing fluids, where operating temperatures typically range from ambient to 400–600°F (200–315°C) – well within its performance range. For precise temperature and pressure limits, engineers should consult manufacturer isocorrosion curves and ASME Section VIII/IX standards.

Suitability for Oilfield Applications

Alloy C-276 is highly suited for demanding oilfield environments, including produced water systems, acidizing operations, and gas sweetening units where hydrochloric acid, organic acids, and chlorides create significant corrosion risks. Its combination of excellent corrosion resistance, strong mechanical properties, and weldability makes it a reliable choice for both shell-and-tube and plate heat exchangers in these challenging applications. Companies like NOVA Petroleum Services can connect operators with trusted manufacturers of Alloy C-276 components, helping tailor material selection to specific CO₂, H₂S, and chloride conditions. They also assist in upgrading equipment from less durable materials when corrosion-related issues become recurring problems. While the initial investment may be higher, the alloy’s performance justifies the cost in harsh environments.

Cost-Effectiveness

The upfront cost of Alloy C-276 is higher than that of 316/317 stainless steels or duplex alloys due to its high nickel, molybdenum, and tungsten content, as well as its more complex manufacturing process. However, it proves to be a cost-effective solution in scenarios where the risk of failure, unscheduled shutdowns, or frequent replacements is significant. Offshore platforms, sour service fields, and facilities handling aggressive produced water or acid systems benefit greatly from the alloy’s extended lifespan and reduced maintenance needs. In some cases, a hybrid approach is employed – using C-276 for critical components like tubes and tubesheets in key exchangers while opting for lower-cost alloys elsewhere. This strategy helps balance overall costs while safeguarding essential equipment.

Heat Exchanger Fouling and Corrosion

Material Comparison Table

When choosing materials for an oilfield heat exchanger, it’s crucial to strike the right balance between corrosion resistance, temperature tolerance, and cost. The table below provides a quick comparison to help you evaluate options based on specific service conditions.

316 stainless steel offers moderate to high corrosion resistance but struggles with chloride stress corrosion cracking when exposed to saline brines above 140°F. Duplex stainless steels (2205/2507) are highly resistant to localized corrosion and provide excellent strength, making them ideal for produced water and seawater coolers. However, they are typically limited to temperatures around 600–650°F to prevent embrittlement. 13Cr martensitic stainless steel is a practical choice for sweet to mildly sour services up to 400–500°F, but it isn’t suitable for environments with aggressive chloride or H₂S exposure.

For harsher conditions, nickel-based alloys stand out. Alloy 825 and Alloy 28 offer exceptional resistance to chlorides, acids, and sour gas, with service temperatures reaching up to 1,000–1,200°F. Alloy 625, with its 9% molybdenum content, excels in seawater and sour brine environments, performing across a wide range of temperatures – from cryogenic levels up to about 1,800°F. Alloy C-276 is a top performer against localized corrosion and mixed acids, operating reliably up to 1,500–1,650°F in chemical and petrochemical applications.

Cost varies significantly based on material performance. While 316 stainless steel and 13Cr are budget-friendly options, duplex stainless steels and alloys like 825 and 28 fall into a mid-range pricing category. Premium materials such as Alloys 625 and C-276 are more expensive due to their high content of nickel, molybdenum, and tungsten.

| Material | Corrosion Resistance | Chloride/Localized Corrosion | Sour Service (H₂S) | Typical Temp Range (°F) | Strength | Common Oilfield Applications | Relative Cost |

|---|---|---|---|---|---|---|---|

| 316 Stainless Steel | Moderate to High | Fair – susceptible to SCC in hot brines | Limited | 32–800 | Standard | Produced water in mild conditions | $ |

| Duplex SS (2205/2507) | High | Very Good – high resistance to attack | Good (moderate H₂S) | 32–600 | High | Produced water coolers, seawater cooling | $ |

| 13Cr Martensitic SS | Moderate | Moderate – SCC risk in sour/high-chloride | Limited (sweet/mildly sour) | 32–500 | High (moderate toughness) | Sweet/mildly sour wells, condensate coolers | $ |

| Alloy 825 | Very High | Very Good | Excellent | 32–1,000 | High | Sour service, high-chloride brines, acid loops | $ |

| Alloy 28 | Very High | Very Good | Excellent | 32–1,200 | High | Chemical processing, acid systems | $ |

| Alloy 625 | Very High to Extreme | Excellent | Excellent | Cryogenic–1,800 | Very High | Seawater coolers, offshore topside, sour gas | $$ |

| Alloy C-276 | Extreme | Excellent (best for pitting/crevice) | Excellent | 32–1,650 | High | Acidizing fluids, wet H₂S/CO₂ services | $$ |

Localized corrosion, such as pitting and crevice attack, often dictates material selection. Use this table as a starting point, but remember to consult manufacturer isocorrosion curves, NACE standards, and ASME Section VIII guidelines to confirm suitability for specific pressure and temperature conditions. For expert guidance on equipment selection and upgrades, visit NOVA Petroleum Services.

Conclusion

Selecting the right alloy for your heat exchanger means aligning it with the specific demands of your system’s corrosive fluids, temperature, and pressure. Start by assessing whether your equipment encounters seawater, acids, chlorides, or H₂S. Pair this with a review of your operating temperature and pressure requirements. Conducting a detailed corrosion audit of your current equipment can highlight failure trends and guide you toward materials that can truly withstand your working environment. Matching material properties to field conditions is key to achieving long-term reliability.

While cost is always a factor, technical performance often holds greater weight. Consider the balance between upfront material cost and total ownership expenses. For instance, 316 stainless steel, priced at $4–6 per pound, may last 5–10 years, whereas Alloy C-276, at $20–30 per pound, can provide over 20 years of service. Case studies show that investing in higher-grade alloys often leads to less downtime and lower maintenance costs over time. Additionally, take into account factors like fabrication, thermal conductivity, and weldability. Some materials with excellent corrosion resistance may pose challenges during manufacturing or result in reduced heat transfer efficiency. Testing prototypes under conditions that closely resemble your actual process can help you avoid costly missteps.

For high-quality process equipment, including heat exchangers made from corrosion-resistant alloys, NOVA Petroleum Services is a trusted source. With over 140 years of oilfield equipment manufacturing expertise, they supply products from industry leaders across the USA, Canada, the UK, and the European Union. Whether you need equipment renewal, replacement, or upgrades, NOVA Petroleum Services offers tailored solutions that strike the right balance between performance and cost efficiency.

FAQs

What should I look for when selecting materials for heat exchangers in oilfield applications?

When choosing materials for heat exchangers in oilfield settings, corrosion resistance should be a top priority. These systems frequently deal with aggressive chemicals and fluids, which can cause significant wear if the wrong materials are used. It’s also important to account for operating temperature and pressure conditions, as the material must withstand the extreme environments common in oilfield operations.

Another key consideration is compatibility with oilfield fluids, such as hydrocarbons or saline water, to prevent long-term degradation. On top of that, look at the material’s durability and maintenance needs – this can help reduce downtime and keep the equipment running longer. By weighing these factors carefully, you can ensure the heat exchanger performs reliably under tough conditions.

How do the costs of materials like Alloy 625 and Alloy C-276 compare to their durability and performance?

Alloy 625 and Alloy C-276 stand out as top-tier materials, celebrated for their outstanding resistance to corrosion and impressive durability in tough environments. While their initial price tag might be steeper compared to other options, their extended lifespan and dependable performance in harsh conditions often justify the investment in the long run.

These alloys shine by cutting down on maintenance demands and reducing how often equipment needs replacing. This can translate to significant savings in overall operational costs, particularly in industries like oil and gas, where reliable equipment is absolutely essential.

Why is duplex stainless steel a better choice than 316 stainless steel for tough oilfield environments?

Duplex stainless steel is a popular alternative to 316 stainless steel in tough oilfield environments due to its superior resistance to corrosion, especially in harsh settings with chlorides or sulfides. Its enhanced strength and durability make it an excellent choice for applications where dependable performance is a must.

What sets duplex stainless steel apart is its blend of toughness and resistance to stress corrosion cracking. This combination not only extends its service life but also helps lower maintenance and replacement expenses in demanding conditions.