HPHT (High-Pressure, High-Temperature) LWD (Logging While Drilling) tools are essential for modern drilling in extreme environments. These tools provide real-time data on formation properties, geosteering, and pressure conditions, enabling safer and more efficient drilling in deep, high-pressure wells. Unlike wireline logging, LWD tools transmit data while drilling, eliminating the need to remove the drill string.

Key features include:

- Temperature and Pressure Tolerance: Operate up to 392°F (200°C) and 30,000 psi.

- Advanced Materials: Use Inconel, titanium, tungsten, and carbide for durability.

- Data Transmission: Machine-learning-powered telemetry increases data rates by up to 400%.

- Critical Measurements: Gamma ray, resistivity, neutron-density, and Pressure-While-Drilling (PWD) sensors provide actionable insights.

Field examples, like Chevron‘s Gulf of Thailand project, demonstrate zero failures and millions in cost savings. Innovations such as machine learning and digital tools are improving accuracy, reliability, and efficiency for HPHT operations.

HPHT LWD tools are vital for drilling in challenging conditions, ensuring accurate data collection and reducing risks during operations.

Design and Engineering of HPHT LWD Tools

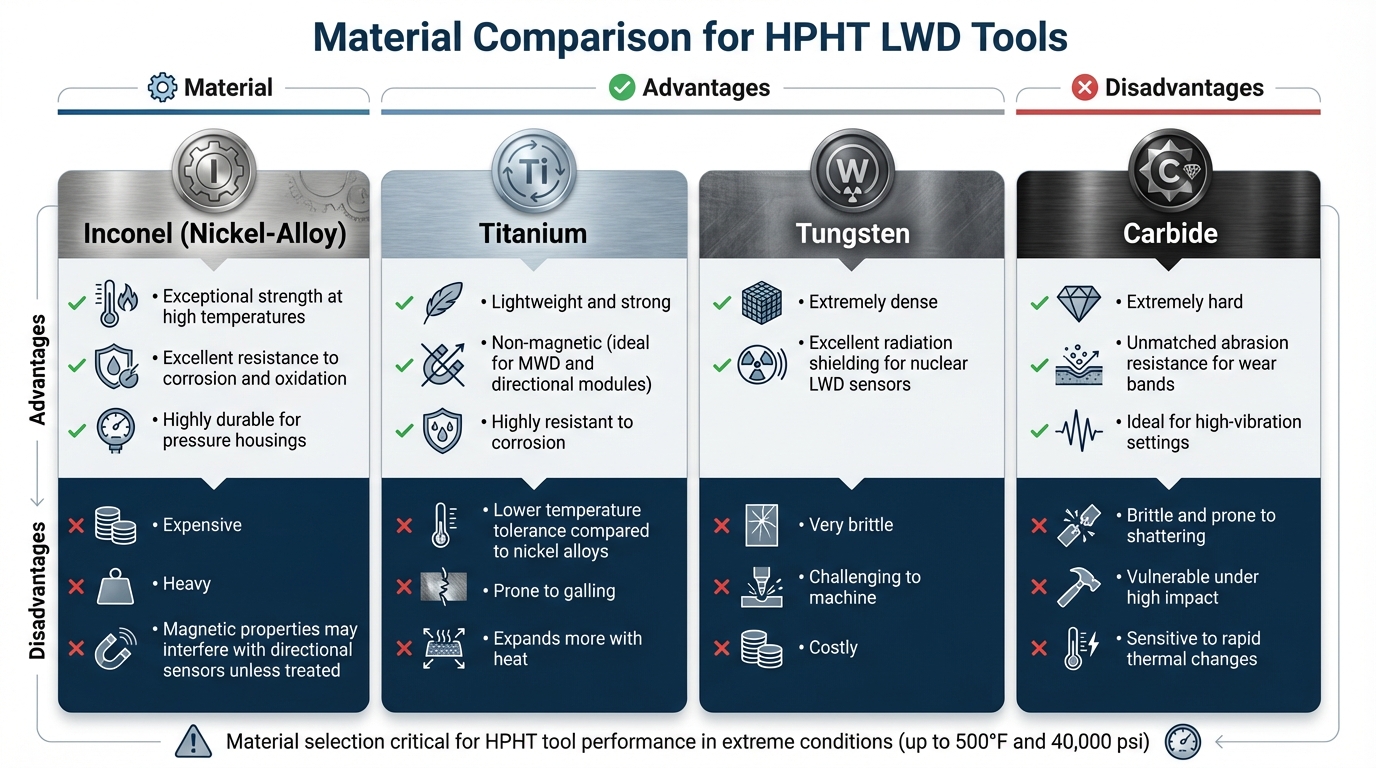

HPHT LWD Tool Material Properties Comparison Chart

Key Design Features

HPHT LWD tools are built to endure conditions that would destroy standard equipment. These tools rely on hybrid circuitry mounted on ceramic substrates, allowing them to function at temperatures far beyond the limits of traditional circuit boards. This ensures that quartz pressure transducers remain accurate, even in extreme heat.

Managing heat is another critical aspect. Electronics are protected inside Dewar flasks equipped with heat sinks and low-power designs, which slow down temperature increases and enable measurements to be completed without failure.

Seals and elastomers are constantly tested by the harsh combination of heat and pressure. Standard O-rings simply don’t hold up in HPHT wells. Instead, advanced PTFE seals can handle up to 610°F (321°C), while metal seals are used for shorter durations at temperatures exceeding 800°F (427°C). As Joseph Edone from Scientific Drilling International notes, "High temperatures are particularly wearing on O-rings and seals, so all are replaced before the tools are reassembled and tested".

Vibration protection is equally crucial. These tools are designed to withstand intense shocks and vibrations with features like floating gamma chambers, top-mounted pulsers, carbide wear bands, and tungsten shields. Some components are robust enough to handle up to 45 G RMS .

Power systems in HPHT tools also need to cope with extreme conditions. Lithium thionyl chloride batteries, known for their high power density and temperature tolerance, are the go-to choice for these applications. Additionally, machine-learning-enhanced telemetry systems have revolutionized data transmission, achieving rates that are 400% faster than previous methods. This is especially impressive given the challenges posed by high-density drilling fluids, which tend to weaken signal strength.

These innovations collectively ensure that HPHT LWD tools perform reliably in some of the harshest drilling environments.

Material Comparison Table

The materials used in HPHT tools can make the difference between success and failure. Each material offers unique benefits and trade-offs:

| Material | Advantages in HPHT | Disadvantages in HPHT |

|---|---|---|

| Inconel (Nickel-Alloy) | Exceptional strength at high temperatures; excellent resistance to corrosion and oxidation; highly durable for pressure housings. | Expensive; heavy; magnetic properties may interfere with directional sensors unless treated. |

| Titanium | Lightweight and strong; non-magnetic, making it ideal for MWD and directional modules; highly resistant to corrosion. | Lower temperature tolerance compared to nickel alloys; prone to galling; expands more with heat. |

| Tungsten | Extremely dense; provides excellent radiation shielding for nuclear LWD sensors. | Very brittle; challenging to machine; costly. |

| Carbide | Extremely hard, offering unmatched abrasion resistance for wear bands in high-vibration settings. | Brittle and prone to shattering under high impact or rapid thermal changes. |

HPHT tools are categorized into performance tiers based on their temperature and pressure limits. Standard tools are rated for up to 302°F (150°C) and 10,000 psi. HP/HT tools can handle up to 399°F (204°C) and 20,000 psi. Ultra-HP/HT tools are designed for up to 500°F (260°C) and 35,000 psi, while the most advanced HP/HT-hc systems operate between 500°F and 599°F (260°C–315°C) at pressures as high as 40,000 psi.

Applications of HPHT LWD Tools

Key Measurements

HPHT (High-Pressure, High-Temperature) LWD tools are vital for making informed drilling decisions in real time. Take azimuthal gamma ray sensors, for example. These sensors measure natural radiation across 16 sectors, enabling engineers to calculate shale volumes and align reservoir models – all while the drill bit is actively cutting through rock. This ensures the wellbore stays precisely on track.

Resistivity measurements use electromagnetic waves to detect hydrocarbons and calculate water saturation. These systems can identify reservoir and fluid boundaries up to 225 feet (68 meters) away from the wellbore. Meanwhile, neutron porosity sensors measure the hydrogen index to estimate fluid-filled pore space, helping distinguish between gas and oil while fine-tuning water saturation calculations.

For determining lithology and porosity, formation density tools measure bulk density and the photoelectric factor (Pe). Pressure-while-drilling (PWD) sensors provide real-time data on bore and annular pressure, allowing operators to monitor equivalent circulating density (ECD), assess pore pressure, and avoid hazards like kicks. Additionally, nuclear magnetic resonance (NMR) offers a non-radioactive way to measure porosity while delivering unique insights into permeability and fluid viscosity.

Acoustic logging measures how sound waves travel through rock, revealing mechanical properties and porosity. At the same time, borehole imaging uses ultrasonic or electrical readings to create detailed visuals of the borehole wall, identifying fractures, stress orientation, and facies. These tools collectively provide a comprehensive understanding of the formation as drilling progresses, enabling precise decision-making.

Field Use Cases

From 2018 to 2019, Chevron deployed Weatherford‘s HeatWave Extreme (HEX) LWD service across 22 ultra-high-temperature offshore wells in the Gulf of Thailand. The operation achieved zero failures and saved an estimated $4 million.

"The HeatWave Extreme service reliably acquires gamma ray, resistivity, neutron-porosity, bore and annular pressure, and density data at high temperatures without extra trips or temperature mitigation."

– Weatherford

In China’s Tarim Basin, NOV‘s Hellfire MWD/LWD system successfully drilled a vertical deep gas well from 6,476 meters to 7,700 meters TVD over 388 circulating hours across six runs. The system operated flawlessly at 302°F (150°C). In Veracruz, Mexico, the same system reached a total depth of 7,714 meters in two simultaneous HPHT wells, handling pressures over 18,000 psi and static temperatures of 347°F (173°C). It delivered reliable real-time data despite extreme vibrations and low flow rates.

In West Texas’s Permian Basin, an operator used the Accusteer LWD system to drill an 8,125-foot lateral. Leveraging 16-sector azimuthal gamma readings for geosteering, the team kept the wellbore within the target zone for 4,000 feet without needing to adjust for inclination corrections. The lateral was completed in just two days. Meanwhile, a geothermal project in France utilized the Hellfire MWD system to directionally drill a 5,447-meter deep well. The system performed under extreme conditions, with circulating temperatures reaching 365°F (185°C) and static temperatures exceeding 392°F (200°C), achieving total depth despite intense vibrations.

"The system’s data transmission rates are up to 400% faster than the current industry standard – enabled by leveraging advanced pulser electronics with machine-learning-driven pulse decoding."

– Kirby Wedewer, Product Line Director, NOV

Operational Best Practices for HPHT LWD Tools

Pre-Deployment Preparation

Before deploying HPHT LWD tools, it’s crucial to draft a Service Quality Plan (SQP) that addresses personnel requirements, risk management, and equipment qualifications tailored to the specific well conditions. A key step in preparation is conducting heat qualification tests in specialized ovens. Gradually increasing the temperature allows you to pinpoint potential equipment failures in a controlled environment.

"It is preferable to identify potential failures in a controlled lab setting rather than at the wellsite which may result in NPT and therefore cost."

– Jack Willis, Managing Director, one&zero

The temperature should be raised in 25°C increments every 30 minutes, reaching the expected Bottom Hole Temperature (BHT), and then cooled at the same rate. This controlled process minimizes thermal shock, which can occur due to differences in Coefficients of Thermal Expansion (CTE) across materials – one of the main causes of electronic failures in high-pressure, high-temperature environments. While the tool is powered during these tests, performing internal calibrations can help identify any sensor drift caused by heat exposure.

For each run, it’s essential to use elastomers and O-rings specifically designed for HPHT conditions. Equipment should be selected based on the mission profile, ensuring tools are rated for the maximum expected BHT and pressure (typically 175°C–200°C [347°F–392°F] and up to 35,000 psi). Between 1997 and 2003, Halliburton‘s Sperry-Sun division tested an HT-LWD suite (Solar 175) in the North Sea, achieving depths over 15,000 feet and temperatures up to 186°C (367°F). This rigorous testing demonstrated that proper component-level qualification can extend system life, targeting a mean time between failures (MTBF) of over 100 hours at 175°C.

Thorough pre-deployment testing ensures tools are ready to handle the dynamic conditions of HPHT wells. These steps lay the groundwork for effective real-time monitoring and reliable backup systems.

Real-Time Monitoring and Backup Systems

Real-time monitoring is critical in HPHT operations, and Pressure-While-Drilling (PWD) sensors play a key role by detecting kicks through sudden pressure changes downhole. Telemetry systems – whether mud pulse, electromagnetic, or acoustic – transmit annular and internal pressure data, improving both safety and efficiency. Advances like machine-learning-enhanced telemetry have significantly boosted data transmission rates, achieving up to 400% faster speeds compared to older methods.

To ensure data integrity during telemetry interruptions or when pumps are off, memory-based logging systems are used. A notable example is NOV’s Hellfire MWD system, which operated for 388 circulating hours across six runs in the Tarim Basin, enduring temperatures up to 302°F (150°C) without failure. This included a single run lasting 175 hours. Monitoring Equivalent Circulating Density (ECD) and annular pressure in real time also helps prevent issues like lost circulation and inefficient cuttings removal.

To protect tools from prolonged exposure to extreme temperatures, optimized logging plans are essential. Activating tool electronics only at logging depth reduces heat generation. Additionally, performing cooling wiper trips between runs helps lower the wellbore’s temperature before deploying sensitive equipment. Using memory-based tools on slickline instead of traditional conductor lines can also simplify operations and reduce toolstring weight.

Best Practices Comparison Table

| Practice Category | Standard Drilling Practice | HPHT-Specific Best Practice | Benefit |

|---|---|---|---|

| Elastomer Maintenance | Periodic inspection and replacement based on wear | Replace all O-rings and elastomers after every run | Prevents pressure-induced seal failure |

| Tool Testing | Standard functional bench tests | Gradual heat ramp in specialized ovens (25°C increments) | Identifies solder/component fatigue early |

| Electronics Management | Tools powered on during entire trip | Power on electronics only at logging depth | Reduces internal heat and extends component life |

| Telemetry Backup | Reliance on real-time mud pulse telemetry | Dual real-time and memory-based logging | Ensures data recovery during telemetry interruptions |

| Logging Strategy | Focus on high-resolution data acquisition | Prioritize critical data first and minimize thermal exposure time | Reduces time at peak temperatures |

| Wellbore Preparation | Standard circulation | Schedule cooling trips between runs | Lowers ambient stress on electronics |

sbb-itb-325a090

NOVA Petroleum Services‘ HPHT LWD Solutions

HPHT Equipment Distribution

When it comes to tackling the harshest drilling conditions, NOVA Petroleum Services stands out by offering top-tier HPHT (high-pressure, high-temperature) LWD (logging while drilling) tools from leading manufacturers in the USA, Canada, the UK, and the European Union. Their lineup includes cutting-edge systems like NOV Tolteq Hellfire and Weatherford HeatWave Extreme, both designed to thrive in environments where temperatures soar up to 392°F (200°C) and pressures exceed 30,000 psi.

The Tolteq Hellfire platform is a game-changer. Its top-mount pulsers prevent drillstring bounce and ensure axial retention, cutting failure rates by around 25% compared to traditional bottom-mount designs. For added durability, its gamma modules feature floating chambers that shield sensitive components, keeping them functional even under extreme vibration – up to 45 G RMS. Plus, its machine-learning-powered telemetry boosts data transmission speeds by up to 400%.

"The Hellfire platform… has proven itself reliable and robust in harsh, hot, high-pressure, vibration-prone operating conditions."

– Kirby Wedewer, Product Line Director, NOV

On the other hand, Weatherford HeatWave Extreme takes real-time data collection to the next level. With integrated sensors for azimuthal gamma ray, resistivity, neutron-porosity, and density readings, it eliminates the need for additional trips to handle temperature mitigation. A Chevron case study highlighted its performance, logging data from 22 ultra-high-temperature wells without a single failure – saving the client $4 million. Every component, from electronics to elastomers, is built to withstand extreme heat and vibration.

To complement these advanced tools, NOVA Petroleum Services ensures customers receive exceptional post-sale support, keeping operations running smoothly in even the toughest conditions.

Customer Support and Services

High-performance tools demand equally high-quality support, and NOVA Petroleum Services delivers on this front. Beyond supplying advanced HPHT equipment, the company offers comprehensive lifecycle support that includes renewal, replacement, and upgrades. With over 140 years of experience in oilfield equipment, their team ensures operators achieve consistent performance from their tools.

"We offer additional levels of customer support, including renewal, replacement, or upgrading of equipment, with an extensive product and service offering to ensure total customer satisfaction."

– NOVA Petroleum Services

From their hubs in Houston, Texas, and Edmonton, Alberta, NOVA Petroleum Services provides seamless supply chain integration, parts provisioning, technical services, and training programs. This ensures operators not only gain access to advanced technology but also benefit from ongoing support throughout the equipment’s lifecycle. By combining cutting-edge tools with stellar customer service, NOVA Petroleum Services ensures operators are always prepared to face the challenges of extreme drilling environments.

Future Trends in HPHT LWD Technology

Digital Twins and Predictive Analytics

The drilling industry is moving away from traditional, reactive maintenance approaches and embracing predictive, condition-based strategies. These programs focus on monitoring tool performance in extreme environments. Advanced software platforms like ToolTracker play a key role by recording real-time downhole conditions – such as temperature, shock, and vibration – for individual modules. This allows operators to predict servicing needs based on actual wear rather than relying on fixed maintenance schedules, ultimately improving tool utilization in HPHT wells.

"This enables users to track usage and downhole conditions on each individual module and apply condition-based maintenance programs." – Kirby Wedewer, Product Line Director for RSS, NOV

Additionally, genetic algorithms are being used to fine-tune calibration, improving both inclination and azimuth accuracy. These digital insights are paving the way for new autonomous technologies, which are transforming how downhole communication and control are managed.

Autonomous and Machine Learning Tools

Autonomous tools powered by machine learning are complementing digital twin technology by enhancing real-time data flow and tool performance. For example, machine learning-driven pulse decoding has achieved up to a 400% increase in data transmission rates compared to older methods. Meanwhile, advanced surface decoders can now detect mud pulses as short as 0.125 seconds, enabling toolface updates as frequently as every two seconds.

To make the most of limited bandwidth, new compression algorithms have been developed, reducing the size of downhole data by 25% without sacrificing data quality. This ensures that more real-time information reaches the surface, even in challenging conditions. These advancements are enabling operators to navigate the complexities of HPHT environments with greater precision and efficiency.

Conclusion

HPHT LWD tools are indispensable as drilling ventures push into deeper, hotter, and more demanding reservoirs. These advanced tools provide real-time insights into formation characteristics and drilling parameters, even in extreme downhole conditions where traditional equipment falls short. By delivering crucial data while drilling, they significantly lower the risks associated with wireline logging in unstable boreholes, where tool deployment can often be compromised.

The benefits of HPHT LWD tools extend beyond just data acquisition. Field applications have shown notable cost reductions and operational gains, with some projects achieving zero tool failures, reducing drilling time, and setting new benchmarks for performance in ultra-high-temperature environments.

Recent advancements, such as machine learning-enhanced pulse decoding, have pushed data transmission speeds to levels up to 400% faster than previous industry norms. With surface decoders now capable of detecting mud pulses as brief as 0.125 seconds, operators can make faster, better-informed decisions to enhance well placement and reduce risks. These innovations ensure that HPHT LWD tools remain reliable and efficient under the most extreme conditions.

NOVA Petroleum Services leverages these advancements to provide top-tier HPHT drilling solutions sourced from leading manufacturers across the USA, Canada, the UK, and the European Union. With services that include equipment renewal, replacement, and upgrades, NOVA ensures operators can maintain consistent performance in challenging environments. As the market for wells exceeding 150°C continues to grow at an estimated 1% annually, having a dependable partner for HPHT equipment is more important than ever for achieving operational success.

FAQs

What are the main benefits of using HPHT Logging While Drilling (LWD) tools compared to traditional wireline logging?

HPHT LWD tools are designed to gather real-time data while drilling, even in extreme high-temperature and high-pressure conditions. These tools measure key parameters such as gamma-ray, resistivity, neutron density, and pressure, enabling immediate well placement and ongoing reservoir evaluation – all without halting operations or removing the drill string.

On the other hand, traditional wireline logging comes with notable limitations. It struggles with high-temperature environments, requires the drill string to be pulled out of the well, and only provides data after the logging process is completed. By cutting out these delays, HPHT LWD tools significantly improve operational efficiency and support quicker, more informed decision-making in tough drilling scenarios.

How can machine learning improve telemetry systems in HPHT Logging While Drilling (LWD) tools?

Machine learning offers a promising way to boost the performance of telemetry systems operating in high-pressure, high-temperature (HPHT) environments. By using advanced algorithms, these systems can achieve better signal-to-noise ratios, apply adaptive data compression, and utilize predictive error correction. The result? More reliable communication, even in the toughest downhole conditions.

Traditional methods like mud-pulse and optical communication are still widely used, but incorporating machine learning could make these approaches faster and more dependable. This means less downtime and greater efficiency. As the oil and gas industry pushes forward with new innovations, machine learning is set to become a key player in refining HPHT LWD technologies.

What materials are used in HPHT LWD tools to handle extreme pressure and temperature, and what makes them effective?

HPHT (high-pressure, high-temperature) LWD tools are engineered with materials specifically designed to handle extreme environments, such as temperatures surpassing 600°F and pressures exceeding 10,000 psi. These tools incorporate high-temperature elastomers, PTFE-based polymers, and ceramic-based electronics to ensure reliable performance under such harsh conditions.

Temperature-resistant elastomers play a critical role in seals and O-rings, maintaining flexibility and preventing leaks even as metals expand due to intense heat. PTFE-based polymers, like Parfluor Ultra, provide excellent resistance to chemicals such as H₂S and hydrocarbons, while also withstanding abrasion from cuttings. These polymers can function continuously at 610°F and can handle intermittent exposure up to 800°F when used alongside metal seals.

For electronic components, ceramic substrates replace conventional materials, offering enhanced thermal stability. This allows for precise measurements using quartz-based pressure transducers, even in ultra-high-pressure environments. Together, these advanced materials ensure the durability and reliability of tools designed for the extreme demands of ultra-deep drilling. NOVA Petroleum Services delivers solutions incorporating these technologies, tailored for U.S. operators.