Corrosion in the oil and gas industry, especially in environments with hydrogen sulfide (H₂S), can lead to costly failures and safety risks. NACE MR0175/ISO 15156 is the go-to standard for selecting materials that resist cracking in sour service conditions. It provides guidelines for choosing metals like carbon steel and corrosion-resistant alloys (CRAs) to prevent issues like sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC).

Key points:

- NACE MR0175/ISO 15156 is critical for upstream oil and gas operations in H₂S-rich environments.

- It outlines material requirements, including hardness limits, chemical composition, and heat treatment.

- Compliance ensures safer operations, reduces failures, and minimizes downtime.

- NACE MR0103 focuses on downstream applications with milder H₂S conditions.

Understanding and applying these standards is vital for oilfield safety and reliability. The article explores the differences between MR0175 and MR0103, material categories, testing requirements, and how companies ensure compliance.

Understanding difference between NACE MR0175 and MR0103 wrt 3 Key parameters

NACE MR0175/ISO 15156 Explained

NACE MR0175/ISO 15156 serves as the cornerstone standard for selecting metallic materials that can resist cracking in sour service environments. Officially titled "Petroleum and natural gas industries – Materials for use in H₂S‐containing environments in oil and gas production," this joint NACE–ISO standard provides guidelines for identifying and qualifying materials capable of withstanding hydrogen sulfide (H₂S) exposure without failure.

The standard applies to equipment used across oil and natural gas production and treatment facilities where H₂S is present. Failures in such environments could jeopardize safety and compromise equipment integrity. It is divided into three parts: Part 1 lays out general principles for selecting cracking-resistant materials; Part 2 focuses on carbon and low-alloy steels, including cast irons; and Part 3 addresses corrosion-resistant alloys.

At its core, the standard highlights specific cracking mechanisms that can challenge material performance under sour conditions.

What NACE MR0175 Covers

This standard zeroes in on cracking mechanisms caused by H₂S, such as sulfide stress cracking (SSC), hydrogen-induced cracking (HIC), stress-oriented hydrogen-induced cracking (SOHIC), and stress corrosion cracking (SCC). Unlike general corrosion, which results in gradual material loss, H₂S-driven cracking is more insidious. It involves hydrogen permeating the material, causing localized embrittlement that can lead to sudden and brittle failure – even when visible corrosion appears minimal. The standard emphasizes that qualified materials are resistant to cracking in specific H₂S environments, though they may not be immune to all conditions.

Requirements for Compliance

Compliance with NACE MR0175 calls for meticulous control of material hardness, chemistry, and microstructure to minimize cracking risks in sour environments. The standard specifies maximum hardness limits – commonly measured in Rockwell C (HRC) – for both base materials and welds to reduce susceptibility to SSC. For instance, many carbon steels must maintain a hardness level of 22 HRC or lower to ensure effective SSC resistance. Additionally, it outlines strict chemical composition ranges and heat-treatment protocols to avoid the development of harmful phases that could heighten cracking risks.

The responsibilities for compliance are clearly delineated. Operators (end users) must first define the service environment where the equipment will be used. Manufacturers and suppliers are then tasked with ensuring their products meet the necessary metallurgical, hardness, testing, marking, and documentation standards. This includes providing traceable mill certificates and test records as proof of compliance.

These stringent measures directly influence material selection and equipment durability, forming a critical part of the broader integrity management strategy essential for safe oilfield operations. Companies like NOVA Petroleum Services and Atokan Drilling Technologies Inc supply NACE-compliant equipment – such as OCTG, progressive cavity pumps, plunger pumps, and production solutions – from trusted manufacturers in the U.S., Canada, the UK, and the European Union to meet these rigorous standards and ensure long-term reliability.

NACE MR0175 vs. MR0103

NACE MR0175 vs MR0103 Standards Comparison for Oil and Gas

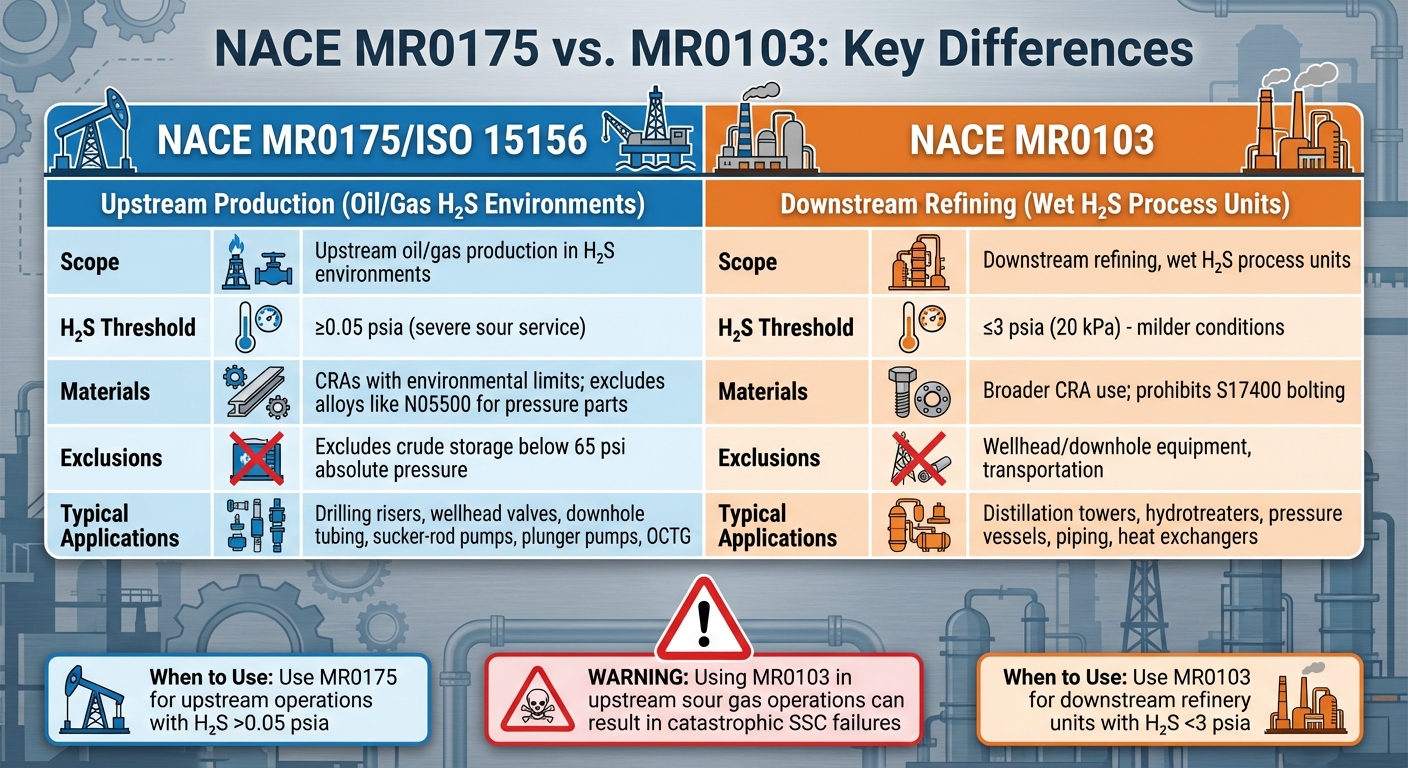

NACE MR0175/ISO 15156 focuses on upstream oil and gas production, while MR0103 is tailored for downstream refining and petrochemicals. Knowing when to apply each standard is critical to selecting appropriate materials and preventing costly failures in corrosive environments.

How the Standards Differ

These two standards differ in their scope, H₂S thresholds, and material requirements. MR0175 is designed for harsh sour service conditions typically found in exploration, production, and injection operations, where H₂S partial pressures reach 0.05 psia or higher. On the other hand, MR0103 addresses less severe conditions in refineries, where H₂S partial pressures remain at or below 3 psia (20 kPa), such as in distillation towers and hydrotreaters.

| Aspect | NACE MR0175/ISO 15156 | NACE MR0103 |

|---|---|---|

| Scope | Upstream oil/gas production in H₂S environments | Downstream refining, wet H₂S process units |

| H₂S Threshold | ≥0.05 psia, severe sour service | ≤3 psia (20 kPa), milder conditions |

| Materials | CRAs with environmental limits; excludes alloys like N05500 for pressure parts | Broader CRA use; prohibits S17400 bolting |

| Exclusions | Excludes crude storage below 65 psi absolute pressure | Wellhead/downhole equipment, transportation |

Both standards enforce hardness limits specific to their applications. MR0175 requires stringent heat treatment and HIC testing for production environments. Meanwhile, MR0103 is more flexible with corrosion-resistant alloys in lower H₂S conditions but restricts certain materials, such as forbidding S17400 (17-4PH) bolting.

These differences are key in guiding material selection and managing risks in various operational contexts.

When to Use Each Standard

Choosing the right standard is essential for maintaining safety and performance.

Use MR0175 for upstream oilfield equipment exposed to sour gas production where H₂S partial pressure exceeds 0.05 psia. This includes components like drilling risers, wellhead valves, downhole tubing, sucker-rod pumps, plunger pumps, and OCTG in high-risk SSC areas. All wetted parts, including bolting like ASTM A193 B7M, must meet MR0175 requirements in such environments.

Opt for MR0103 when working with downstream refinery equipment, such as pressure vessels, piping, and heat exchangers, in process units where H₂S levels are below 3 psia. However, MR0103 should not be used for wellhead or downhole components, as these fall outside its scope. Applying MR0103 in upstream sour gas operations can result in catastrophic SSC failures, potentially necessitating costly material upgrades to meet MR0175 standards.

Companies like NOVA Petroleum Services offer MR0175-compliant equipment, including OCTG, progressive cavity pumps, and other production solutions, sourced from manufacturers in the U.S., Canada, the UK, and the European Union. This ensures the proper materials are used for demanding upstream applications.

sbb-itb-325a090

Material Categories Under NACE Standards

NACE MR0175/ISO 15156 categorizes materials into two main groups: carbon/low alloy steels and corrosion-resistant alloys (CRAs). Part 2 of the standard focuses on cracking-resistant carbon and low alloy steels (including cast irons), while Part 3 addresses cracking-resistant CRAs and other alloys. Each group comes with specific guidelines for hardness, heat treatment, and environmental conditions, which dictate their safe usage in sour service environments.

A corrosion-resistant alloy (CRA) is defined by the standard as an alloy designed to withstand general and localized corrosion in oilfield environments that would otherwise degrade carbon steels. Importantly, no material is universally "NACE-compliant." Suitability depends entirely on the process conditions, including H₂S partial pressure, temperature, chloride concentration, pH, and stress levels. Below, we explore the requirements for both carbon/low alloy steels and CRAs.

Carbon and Low Alloy Steels

Carbon and low alloy steels are common in oilfield applications like piping, vessels, and OCTG due to their affordability and dependable performance. However, they are prone to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC) when exposed to H₂S environments.

To meet NACE MR0175 standards, these materials must adhere to stringent hardness limits – generally capped at around 22 HRC – and specific metallurgical conditions outlined in Part 2 of the standard. These requirements apply to both the base material and welds, with detailed tables specifying acceptable grades by product form. Compliance is typically verified through mill test reports and hardness testing as prescribed in the standard.

For example, in a moderately sour gas well with low H₂S partial pressure and moderate temperatures, carbon steel tubing that meets Part 2 hardness limits may suffice. Operators often pair this with corrosion inhibitors to mitigate general corrosion and control SSC risks. However, when environmental conditions exceed these limits, additional measures like internal coatings or a switch to CRAs may become necessary.

Understanding these material constraints is critical for selecting alternatives that can handle more demanding conditions.

Corrosion-Resistant Alloys (CRAs)

CRAs encompass a range of materials, including stainless steels, nickel-based alloys, duplex and superduplex stainless steels, and other high-alloy systems. These materials are better suited for higher temperatures and greater H₂S exposure, maintaining their passivity where carbon steels would fail.

Part 3 of MR0175/ISO 15156 categorizes CRAs into martensitic, precipitation-hardening, austenitic, duplex, and nickel-based alloys, each with specific limits. The standard sets maximum hardness values, acceptable heat-treatment or cold-working conditions, and environmental limits for each alloy group, defined by factors like H₂S partial pressure, temperature, and chloride concentration. Selecting the right alloy is essential to meet the rigorous conditions outlined for equipment applications.

Some materials once widely used have been restricted or banned in certain roles. For instance, N05500 (Monel K-500) and N07750 (Inconel X-750) are no longer allowed for pressure-retaining components like bolting, shafts, and stems due to insufficient ductility, though they may still be used for internal springs. Similarly, certain duplex stainless steels are limited to specific temperatures and H₂S partial pressures to avoid stress-corrosion cracking in high-chloride environments.

In challenging scenarios like deeper, hotter sour wells with high H₂S partial pressures and chloride-rich produced water, carbon steel often falls outside the acceptable NACE environmental parameters. In such cases, designs typically shift to CRA tubing, such as duplex or nickel-based alloys, that comply with Part 3 requirements for these extreme conditions.

To support these high-risk upstream operations, NOVA Petroleum Services sources NACE-compliant CRA tubing and production equipment from trusted manufacturers in the U.S., Canada, the UK, and the European Union. This ensures access to materials capable of withstanding the harshest environments.

Using NACE Standards for Oilfield Equipment

Applying NACE standards involves carefully aligning material choices with actual field conditions, conducting specific tests, and planning timely upgrades. The standard emphasizes that materials "are resistant to cracking in defined H₂S‑containing environments… but not necessarily immune to cracking under all service conditions". This serves as a reminder of the importance of tailoring material selection to the specific demands of the field.

H₂S Thresholds and Environmental Factors

NACE MR0175’s material selection guidelines highlight the need to define the service environment with precision. For example, environments with an H₂S partial pressure of about 0.05 psi (0.00035 MPa) require sour service materials. However, H₂S levels are just one piece of the puzzle. Operators must also account for system pressure (which can exceed 1,000 psi), temperature (measured in °F in U.S. operations), chloride concentration (in parts per million), pH, and any traces of elemental sulfur or CO₂.

These factors interact in complex ways. For instance, carbon and low-alloy steels may perform well under H₂S partial pressures below 0.1 bar if the temperature stays moderate and the pH remains above 3.5. But their resistance drops significantly as temperatures approach 300°F or chloride levels exceed 50,000 ppm. Similarly, corrosion-resistant alloys (CRAs) like duplex stainless steels are typically restricted to temperatures below 150°C (302°F) and specific H₂S limits to avoid stress-induced cracking.

Testing and Qualification Processes

Meeting NACE standards requires a mix of laboratory and field testing. NACE TM0177 outlines the primary qualification process, which includes several methods to evaluate resistance to sulfide stress cracking. For example, Method A involves exposing tensile specimens to 85% of their yield strength in H₂S-saturated brine for 720 hours. Materials pass if no cracks form and hardness remains at or below 22 HRC.

Hardness testing is particularly critical for carbon steels and welds. The base material, weld metal, and heat-affected zones must all meet specified hardness limits. Manufacturers are required to provide mill test reports documenting material chemistry, heat treatment, and hardness results. Field validation, often guided by NACE SP0775, may include placing corrosion coupons in tubing subs (typically 2 ft or 600 mm long) to monitor real-world corrosion rates. If these rates exceed 0.1 mm per year, it indicates the need for material upgrades or enhanced corrosion control measures. These testing protocols play a direct role in shaping equipment upgrade strategies.

Equipment Upgrades with NACE-Compliant Solutions

Once testing results are in, the next step is to align field conditions with the limits set by MR0175/ISO 15156. For pumping systems like plunger pumps or progressive cavity pumps, upgrades often involve replacing internal components with CRAs such as duplex stainless steel or Monel 400. These materials are designed to handle H₂S partial pressures below 0.1 bar and chloride concentrations under 50,000 ppm, significantly extending equipment lifespan in sour environments – often by two to five times.

For OCTG (oil country tubular goods), upgrades might include switching to API 5CT pipe with controlled hardness or using CRA tubing in harsher conditions. Bolting materials should also meet hardness and material standards.

NOVA Petroleum Services supports these upgrades by sourcing NACE-compliant equipment from top manufacturers in the U.S., Canada, the UK, and the EU. They also assist operators in implementing these changes during planned workovers, helping to reduce downtime and costs. Research shows that using compliant CRAs in high-chloride fields can lower maintenance needs by 30–50% compared to non-compliant options.

Conclusion

NACE standards, especially MR0175/ISO 15156, play a crucial role in managing corrosion, protecting assets, and ensuring safety in sour oilfield environments. These guidelines help minimize failures, extend the lifespan of equipment, and avoid costly issues like containment loss, unplanned shutdowns, and environmental damage.

Staying compliant means using materials within specified limits, supported by proper testing, documentation, and ongoing monitoring. However, it’s important to note that even compliant materials can still face cracking risks, making continuous risk management a critical part of operations. By combining NACE standards with field corrosion data, inspection insights, and effective inhibitor programs, operators can go beyond basic compliance to achieve safer and more efficient performance.

When planning equipment upgrades, it’s wise to collaborate with experts to ensure material choices align with NACE requirements. NOVA Petroleum Services offers NACE-compliant solutions, including pumping systems, artificial lift systems, OCTG, and production equipment sourced from top manufacturers in the U.S., Canada, the UK, and the EU. Their team supports operators through equipment renewal, replacement, and upgrades by managing the technical documentation and certifications needed to meet both internal and regulatory standards. Aligning upgrades with NACE guidance not only enhances safety and reliability but also reduces downtime and delivers long-term cost savings. This comprehensive approach ensures safer operations and more dependable performance in the field.

FAQs

What is the difference between NACE MR0175 and MR0103 standards?

NACE MR0175 and MR0103 serve as key standards in combating corrosion in oilfield equipment, but they tackle different challenges. NACE MR0175 focuses on materials used in sour environments, emphasizing resistance to sulfide stress cracking caused by hydrogen sulfide exposure. On the other hand, NACE MR0103 outlines guidelines for selecting and maintaining materials like carbon and low-alloy steels to address general corrosion issues in oil and gas production systems.

Simply put, MR0175 is all about preventing sulfide stress cracking in sour conditions, while MR0103 takes a broader approach to managing corrosion across various production settings.

What is NACE MR0175, and how does it protect oilfield equipment from sulfide stress cracking?

NACE MR0175 sets essential guidelines for selecting materials that can resist sulfide stress cracking (SSC) in environments containing hydrogen sulfide (H₂S), often referred to as sour service conditions. This standard ensures that materials used in oilfield equipment are specifically tested and chosen to endure the damaging effects of H₂S, which can lead to cracking and equipment failure over time.

Following these standards helps companies improve the safety and reliability of their equipment while minimizing the risk of failures. This, in turn, reduces costly downtime and supports smoother operations in tough working environments.

Why is choosing the right materials for H₂S levels and environmental conditions essential?

Selecting materials that can handle specific H₂S levels and challenging conditions is crucial for preventing corrosion, ensuring safety, and keeping equipment reliable in demanding oilfield environments. Using unsuitable materials can result in equipment failures, expensive downtime, or even safety risks.

Opting for materials that align with NACE standards can significantly improve equipment longevity, lower maintenance expenses, and promote safe, efficient operations. It also ensures compliance with industry regulations while supporting the long-term performance of assets in harsh environments.