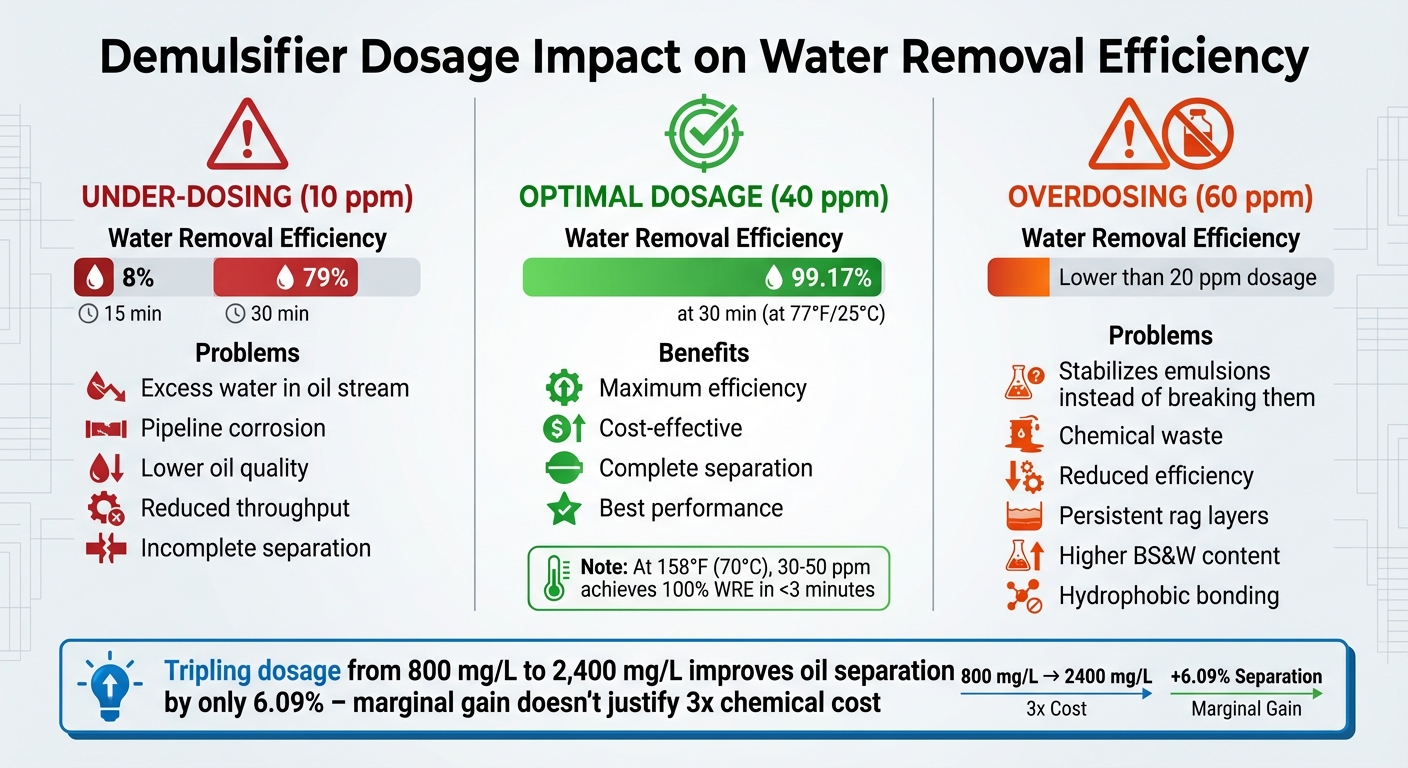

Demulsifiers play a key role in separating water from crude oil during extraction. However, using the wrong dosage – either too little or too much – can lead to poor separation, higher costs, and operational inefficiencies. Research shows:

- Under-dosing leaves excess water in the oil, leading to corrosion, reduced oil quality, and slower processing.

- Overdosing can stabilize emulsions instead of breaking them, wasting chemicals and reducing efficiency.

Studies highlight that the optimal dosage varies based on conditions like temperature, salinity, and crude oil properties. For example:

- At 77°F (25°C), 40 ppm can achieve 99.17% water removal efficiency (WRE) in 30 minutes.

- Higher temperatures (e.g., 158°F) reduce the required dosage and speed up separation.

To determine the right dosage:

- Start with bottle tests to simulate field conditions.

- Use methods like Response Surface Methodology (RSM) for precise optimization.

- Incorporate machine learning (ML) for real-time adjustments as field conditions change.

Field trials and continuous monitoring ensure that dosages remain effective and cost-efficient. Avoid overdosing by monitoring signs like persistent rag layers or reduced WRE, and adjust dosages incrementally based on performance data.

Research Background on Demulsifier Dosage

Emulsion Types and Operating Conditions

Water-in-oil (W/O) emulsions are a common challenge in oilfield operations, particularly in low-permeability reservoirs where crude oil and water mix during extraction. These emulsions are especially stubborn at lower temperatures – around 77°F (25°C) – due to their high viscosity and stable interfaces, which make separation a tough task. Light crude oil emulsions add another layer of difficulty. Compounds like asphaltenes and fine clay particles, such as SiO₂, strengthen the oil-water interface, making natural separation nearly impossible.

Operating conditions significantly influence emulsion stability. For instance, at 77°F, the high viscosity of the emulsion hinders separation, while higher temperatures – around 140–158°F – promote droplet coalescence and improve separation. High salinity, on the other hand, complicates the process by altering interfacial tension and stabilizing the emulsion. When dealing with heavy crude oils, temperatures need to rise even further, to about 149–158°F (65–70°C), as their naturally higher viscosity demands more energy to achieve effective demulsification. These factors directly shape how varying demulsifier dosages impact separation efficiency.

How Wrong Dosage Affects Operations

Getting the dosage wrong – whether too little or too much – can create significant problems. Under-dosing leaves excess water in the oil stream, which leads to pipeline corrosion, lower oil quality, and reduced throughput. For example, at just 10 ppm, water removal efficiency (WRE) reaches only 8% after 15 minutes and 79% after 30 minutes. This incomplete separation introduces water into downstream processes, slowing operations and increasing maintenance needs.

On the flip side, overdosing creates its own set of issues. When concentrations exceed 40 ppm, the excess demulsifier can actually stabilize the emulsion, reducing WRE. At 60 ppm, the efficiency drops below what’s achieved at 20 ppm. Studies also show that increasing PR3 demulsifier concentration from 800 mg/L to 2,400 mg/L improves oil separation by only 6.09%. However, this marginal gain doesn’t justify the tripled chemical cost. Beyond the financial waste, overdosing can lead to hydrophobic bonding, which clumps water droplets together and demands additional corrective treatments. Understanding these effects is crucial for selecting the right demulsifier chemistry.

Common Demulsifier Chemistries

To tackle these challenges, researchers have pinpointed specific demulsifier chemistries that perform well under different conditions. One notable group, polyoxyethylene polyoxypropylene quaternized polyoxyolefins (PR-type demulsifiers), are nonionic surfactants that excel in low-temperature environments. At a dosage of 800 mg/L, PR1, PR2, and PR3 achieved separated water rates of 48.9%, 44.7%, and 47.2%, respectively, after 24 hours. These formulations work by reducing interfacial tension and adsorbing clay particles like SiO₂, enabling efficient flocculation in low-permeability fields where high-temperature demulsifiers often fall short.

Other effective chemistries include resin alkoxylates blended with cationic surfactants, which are particularly suited for high-salinity conditions. For example, a formulated demulsifier labeled DB achieved a 96% demulsification efficiency at just 7 ppm for oil-in-water emulsions, proving that the right chemistry can dramatically lower the required dosage. While cationic surfactants are effective in salty environments, they receive less attention in research compared to nonionic types. A key takeaway from these studies is that multifunctional copolymers, such as PR types, deliver the best results for clay-laden light crudes at lower temperatures. Meanwhile, simpler formulations are more effective at higher temperatures, where Brownian motion and mass transfer dominate the separation process.

Methods for Finding the Right Demulsifier Dosage

Bottle Tests and Lab Procedures

Bottle tests are a tried-and-true method for simulating the conditions of field separation. In these tests, researchers create emulsions that mimic the field’s water cut, salinity, and crude oil characteristics. They then introduce demulsifiers at varying concentrations – typically 10 to 60 ppm, increasing in 5 to 10 ppm increments – into separate bottles. After mixing under controlled shear conditions, the bottles are placed in a thermostatic bath set to temperatures like 77°F, 104–122°F, or 149–158°F, replicating real-world operating environments.

The separation process is closely monitored, particularly focusing on water removal efficiency (WRE) at specific time intervals to gauge how quickly the separation occurs. For example, one study tested a demulsifier labeled "DB" and found it achieved 96% demulsification efficiency at just 7 ppm, while another demulsifier, "D", only reached 82% efficiency at the same dosage. These tests also measure key factors like residual basic sediment and water (BS&W), the volume of separated oil, and the quality of the oil-water interface. The ultimate goal? Pinpointing the lowest concentration that consistently delivers 95–99% WRE within the available residence time, avoiding the pitfalls of both under-dosing and overdosing. These lab results provide the foundation for more sophisticated optimization techniques.

Response Surface Methodology for Optimization

Response Surface Methodology (RSM) takes optimization to the next level by modeling how variables like dosage, temperature, and time interact to impact WRE. Using statistically designed experiments – such as Box-Behnken or central composite designs – RSM systematically adjusts these factors across predefined levels (low, center, and high) to develop a second-order polynomial model that predicts WRE. For instance, in a typical setup, dosage might range from 10 to 60 ppm, temperature from 77 to 158°F, and settling time from 5 to 60 minutes.

Through regression analysis, RSM generates equations and contour plots that highlight the optimal operating window. Research consistently shows that dosage, temperature, and time are the key variables, with higher temperatures often reducing the sensitivity to dosage. This means operators can sometimes trade a modest increase in heating for reduced chemical usage. RSM also identifies the risks of overdosing; for instance, one study revealed that exceeding the optimal dose actually decreased WRE. By pinpointing these "safe zones", operators can maximize separation efficiency while minimizing chemical waste and avoiding re-emulsification. These statistical insights pave the way for even more advanced tools like machine learning to refine dosing in real-time field conditions.

Machine Learning for Dosage Prediction

Machine learning (ML) steps in to tackle the complexity of predicting optimal dosages by analyzing a broader range of variables than RSM can handle. Models such as artificial neural networks, support vector machines, and ensemble methods are trained on bottle-test datasets. These datasets include factors like demulsifier concentration, temperature, contact time, salinity, oil-to-diluent ratio, initial water content, and crude oil properties (e.g., API gravity, viscosity, and asphaltene content). Once trained, these ML models can quickly estimate the ideal dosage and operating conditions to achieve the desired WRE, eliminating the need for exhaustive new lab tests.

What sets ML apart is its ability to capture complex interactions between variables. It can also be integrated into real-time advisory systems that adjust dosages dynamically as field conditions change – whether it’s a shift in crude blends, water cuts, or temperatures. However, for ML to be effective, it requires high-quality training data and rigorous validation. When combined with field production data and dosing hardware from companies like NOVA Petroleum Services or Atokan Drilling Technologies Inc, ML can enable real-time dosage adjustments. Together, RSM and ML create a comprehensive approach, bridging the gap between lab experiments and continuous field optimization.

How do Demulsifier additives break oil/water emulsions?

sbb-itb-325a090

Research Findings on Dosage Ranges and Overdosing

Optimal Demulsifier Dosage Effects: Under-dosing vs Optimal vs Overdosing

Optimal Dosage Ranges from Research

Studies on various oilfield emulsion types reveal that the ideal demulsifier dosage depends heavily on crude oil properties and operating conditions. For instance, in condensate oil emulsions at approximately 77°F (25°C) in low-permeability reservoirs, research shows that applying 800 mg/L of a PR3 demulsifier achieves separated water rates of about 47.2% and oil rates around 36.1% after 24 hours. While increasing the dosage to 2,400 mg/L slightly improves performance – resulting in a 6.09% boost in separated oil – the additional cost of chemicals doesn’t justify the marginal gain.

On the other hand, crude oil water-in-oil emulsions have shown near-complete separation with much lower demulsifier concentrations. For example, one study demonstrated that a mere 40 ppm dose achieved 99.17% water removal efficiency within 30 minutes at 77°F (25°C). At higher temperatures, such as 158°F (70°C), even lower concentrations between 30 and 50 ppm reached 100% efficiency in under 3 minutes. Similarly, gas-field oil-in-water emulsions have proven highly responsive to minimal dosages. A custom demulsifier, labeled "DB", achieved 96% efficiency at just 7 ppm. These findings highlight the importance of tailoring dosage to specific conditions for optimal results.

How Temperature, Time, and Concentration Affect Dosage

Temperature plays a crucial role in determining the effectiveness of demulsifier dosages. For example, at 113°F, applying 10 ppm resulted in only 79% water removal efficiency after 30 minutes. However, increasing the dosage to 40 ppm led to complete separation. At higher temperatures, such as 158°F, the process becomes less sensitive to dosage adjustments. In this scenario, concentrations ranging from 30 to 50 ppm consistently achieved 100% water removal in less than 3 minutes. Additionally, longer settling times can partially compensate for lower dosages at cooler temperatures, while optimal dosages significantly reduce separation time, turning hours-long processes into mere minutes.

What Happens When You Use Too Much Demulsifier

Overdosing on demulsifiers not only wastes resources but can also harm separation efficiency. One study found that increasing the dosage to 60 ppm actually reduced water removal efficiency compared to a 20 ppm dose. This occurs because excessive surfactants crowd the oil-water interface, stabilizing droplets instead of breaking them apart. Signs of overdosing include persistent rag layers, higher basic sediment and water content, and elevated oil-in-water levels in produced water. To avoid these issues, operators should carefully monitor performance and adjust dosages as needed.

Field Workflows for Dosage Optimization

From Lab Screening to Field Trials

The journey from lab screening to field trials starts with bottle tests designed to simulate real-world conditions. These tests mimic site-specific factors like temperature, water cut, and crude oil properties. Once the lab identifies the ideal demulsifier and dosage range, the next step is field trials to confirm the lab results hold up in actual operating conditions.

Field trials should begin at the lower end of the dosage range identified in the lab to minimize costs and avoid overdosing. For example, if lab tests suggest 800 mg/L is effective, that dosage should be the starting point for field trials rather than higher concentrations. Typically, the demulsifier is injected at the first endpoint – such as metering stations or wellhead manifolds – to ensure it has enough time to react before the mixture reaches the separation equipment. Performance indicators like oil and water separation, interface clarity, and BS&W levels are monitored over a 24-hour period to validate effectiveness.

This process bridges the gap between controlled lab tests and field conditions, laying the groundwork for real-time adjustments.

Real-Time Dosage Monitoring and Adjustment

After field trials, real-time monitoring becomes key to fine-tuning chemical injection as operating conditions evolve. Focus on key metrics like water removal efficiency (WRE), BS&W content, oil levels in produced water, and separator interface behavior to determine if the current dosage is still effective.

Temperature changes, for instance, can significantly affect performance. In colder weather, increased viscosity can make demulsification more dosage-sensitive, often requiring higher concentrations or longer settling times. On the other hand, at higher temperatures – around 158°F (70°C) – demulsifiers act faster and need lower dosages; studies show over 82% water removal can occur in under three minutes with minimal chemical use. Adjustments should be made gradually, typically in 10–20% increments, allowing time for the system to stabilize between changes.

It’s equally important to watch for signs of overdosing. Symptoms like thicker rag layers, reduced water removal efficiency despite higher chemical use, or foaming in separators could indicate excessive dosage. Exceeding approximately 40 ppm can backfire, as surplus surfactants may stabilize the emulsion instead of breaking it. Setting maximum dosage limits based on lab findings can help avoid these issues.

Field Application Examples

Industry experience shows that starting with bottle tests and following up with controlled field trials is a proven approach to dosage optimization. Consistency in injection points and mixing conditions is crucial to replicate lab shear forces and residence times effectively.

Developing rule-based adjustment protocols can help manage varying operating conditions. For example, when water cut increases, adjusting dosages per barrel of water – rather than per total barrel – ensures dispersed water gets proper chemical coverage. Similarly, setting dosage benchmarks for specific scenarios like cold starts, high water-cut periods, or shifts in crude composition, and documenting these in standard operating procedures, ensures consistent application across teams and shifts.

Conclusion

Summary of Research Findings

The research highlights a critical takeaway: finding the right demulsifier dosage is more of a balancing act than a one-size-fits-all solution. For instance, studies on water-in-oil emulsions revealed that the optimal dosage for maximum water removal efficiency (WRE) sits around 40 ppm, achieving an impressive 99.17% WRE at 77°F (25°C) within 30 minutes. But here’s the catch – going beyond 40 ppm actually reduces performance, with WRE dropping below what’s achieved at just 20 ppm. Similarly, in condensate systems, while a PR-series demulsifier delivered good results at 800 mg/L, tripling the dose to 2,400 mg/L only improved separated oil rates by a modest 6–14%, making the extra chemical investment hard to justify.

Another key factor is how temperature, residence time, and concentration interact. At higher temperatures, like 158°F (70°C), demulsifiers work faster and require less dosage. For example, over 82% water removal can occur in under three minutes. However, overdosing can backfire – excessive concentrations cause the demulsifier molecules to reorient at the oil–water interface, stabilizing the emulsion instead of breaking it. Essentially, your demulsifier starts behaving like an emulsifier, wasting resources and harming separation efficiency.

Recommendations for Oilfield Operators

To maximize efficiency, oilfield operators should begin with bottle tests on their specific crude and produced water, simulating field conditions for temperature and settling times. Relying solely on vendor recommendations can lead to suboptimal results. Structured approaches like response surface methodology can help map the interactions between dosage, temperature, and time, pinpointing the true optimal dosage rather than relying on guesswork. Testing should also identify the point where overdosing starts to hinder performance, allowing operators to stay well below that threshold in real-world applications.

Operate at the dosage where efficiency levels off. For example, if 40 ppm delivers 99% WRE and increasing the dose to 50 ppm adds no measurable improvement, stick with 40 ppm or slightly less. Keep a close eye on indicators like BS&W content, water cut, and separator interface behavior, making small dosage adjustments (10–20%) as conditions change. Re-testing is essential whenever crude blends, water cut, or solids content shift, as these factors can alter the optimal dosage range. Combining these chemical insights with the right equipment setup will ensure smoother and more cost-effective operations.

Support for Chemical and Equipment Integration

Effective demulsifier programs depend on the seamless integration of chemicals and production equipment. Efficient heaters, separators, and injection systems can significantly reduce chemical consumption by improving mixing and coalescence. NOVA Petroleum Services offers a range of solutions tailored for U.S. operators, including oilfield chemicals, chemical injection pumps, and production/process equipment like separators and dehydration units. Beyond supplying products, the company provides technical support for equipment upgrades, renewals, and replacements, ensuring that chemical and mechanical strategies align perfectly. This alignment is key to locking in the efficiency gains identified through lab-to-field optimization workflows.

FAQs

How do I find the right demulsifier dosage for oilfield operations?

To figure out the correct amount of demulsifier for your operation, begin with laboratory jar tests that mimic the specific conditions of your oilfield. Pay close attention to variables like temperature, oil composition, water salinity, and flow rate to measure how well separation occurs. Use the results from these tests to adjust the dosage for the best possible outcome.

Once the initial dosage is set, regular field testing and monitoring become essential. These ongoing checks help refine the dosage as conditions evolve, ensuring smooth oil-water separation and reducing the risk of interruptions to your operations.

What are the risks of overdosing demulsifiers in oilfield operations, and how can you identify them?

Overusing demulsifiers in oilfield operations can create a range of challenges. One major issue is more stable emulsions, which complicate the oil-water separation process. This can lead to equipment fouling and drive up operational expenses due to unnecessary chemical consumption.

Some common signs of overdosing include:

- Emulsions that remain stubborn and hard to break

- Elevated water levels in the separated oil

- A noticeable drop in the efficiency of separation systems

These problems don’t just affect the quality of production – they also lead to increased maintenance demands and higher overall costs. Keeping a close eye on operations and fine-tuning dosages is crucial to maintaining efficiency and avoiding these pitfalls.

How do temperature and salinity influence demulsifier performance in oilfield operations?

Temperature and salinity are key factors influencing how well demulsifiers perform in oil-water separation. Higher temperatures tend to boost efficiency by lowering the oil’s viscosity, making it easier for the demulsifier to disrupt emulsions. On the other hand, elevated salinity can introduce challenges by altering chemical interactions, which might necessitate tweaking the demulsifier dosage.

For the best results, it’s crucial to keep a close eye on these variables and adjust the demulsifier dosage to suit the specific conditions of the field. This approach ensures smoother separation and helps to reduce operational hurdles.