Butterfly valves are widely used in pipelines to control flow, pressure, and isolation. They are compact, cost-effective, and suitable for a variety of industries, including oil and gas, water treatment, and chemical processing. Here’s a quick breakdown of the main types:

- Concentric (Zero-Offset): Best for low-pressure systems (up to 232 psi). Common in HVAC and water distribution.

- Single-Offset: Handles medium pressures (up to 285 psi) with reduced wear. Ideal for water and utility pipelines.

- Double-Offset (High-Performance): Suitable for medium to high pressures (up to 11,600 psi). Used in oil, gas, and industrial systems.

- Triple-Offset: Designed for extreme pressures and temperatures, offering tight, metal-to-metal sealing. Perfect for steam, refinery, and hazardous pipelines.

- Wafer-Style: Compact and economical, used in low-pressure systems but not for end-of-line service.

- Lug-Style: Allows pipeline isolation for maintenance. Common in industrial and fire protection networks.

- Double-Flanged: Built for high-pressure or large-diameter pipelines, ensuring stability and alignment.

Each valve type serves specific pipeline needs based on pressure, temperature, and application. Selecting the right one ensures reliable operation and reduced maintenance. Below, we explore their features, pressure ratings, sealing capabilities, and typical applications.

Butterfly Valve Types Comparison: Pressure Ratings and Applications

What is a Butterfly Valve? Types, Working, and Applications Explained!

1. Concentric Butterfly Valves

Concentric butterfly valves, also known as centerline or zero-offset valves, are designed with a disc and stem positioned at the center of the valve body. The rotation axis aligns directly with the sealing surface, making them a cost-effective choice for general-purpose isolation tasks. Let’s break down their key technical features.

Pressure Rating

These valves are best suited for low-pressure applications, typically handling pressures below 232 psi. Some models can manage up to 928 psi, but they are not built for systems exceeding 1,450 psi.

Sealing Capability

Concentric butterfly valves use EPDM or Buna-N rubber seats to create a bubble-tight seal. The disc maintains consistent 90° contact with the seat during operation, ensuring reliable sealing in low-pressure and non-critical applications. However, this constant contact leads to wear over time, limiting the valve’s lifespan to approximately 50,000 cycles. Additionally, their sealing performance can weaken at temperatures above 250°F or in abrasive conditions.

Installation Method

These valves are typically installed using wafer-style connections, which are clamped between pipe flanges. This method can reduce installation costs by 30–50%. While lug-style or grooved options are available, they often require a complete system shutdown for maintenance.

Pipeline Applications

Concentric butterfly valves excel in low-pressure systems that transport non-corrosive fluids like water, air, natural gas, or low-pressure chemicals. They are commonly used in HVAC systems, water treatment plants, and general industrial piping where simple on/off control is essential. For instance, in many municipal waterworks across the U.S., resilient-seated wafer designs are employed to handle flows of up to 1,000 gallons per minute at 150 psi, meeting AWWA standards for cost-effective isolation. They are also found in furnace circulation systems and liquefied petroleum gas lines rated up to PN1.6. However, they are not suitable for high-pressure oil and gas applications, where offset valves provide better durability and sealing.

2. Single-Offset Butterfly Valves

Single-offset butterfly valves, also known as single-eccentric valves, are designed to improve performance by positioning the stem slightly behind the disc’s centerline. This offset reduces friction between the disc and the seat, which helps lower wear and extend the valve’s lifespan. Let’s dive into their pressure rating, sealing capability, installation options, and typical uses.

Pressure Rating

Single-offset valves are built to handle low to medium pressures, typically up to Class 150 (285 psi at 100°F). They serve as a middle ground between basic concentric valves and the more advanced double- or triple-offset designs. Always check the manufacturer’s specifications for exact pressure limits.

Sealing Capability

The offset design ensures the disc lifts off the seat as soon as the valve opens, reducing the scraping that can wear down the seal over time. These valves often use soft seats – made from materials like EPDM, NBR, or PTFE – to provide a bubble-tight seal. However, for applications requiring zero leakage, fire-safe performance, or metal-seated configurations, engineers generally turn to double- or triple-offset valves.

Installation Options

Single-offset butterfly valves come in various configurations to suit different pipeline needs:

- Wafer style: Fits between flanges, offering a cost-effective installation.

- Lug style: Bolts individually to the pipeline, simplifying maintenance.

- Double-flanged style: Provides extra stability, especially for larger pipelines or buried installations.

These options make single-offset valves versatile for different setups and requirements.

Common Applications

Single-offset butterfly valves strike a balance between improved performance and cost-efficiency, making them ideal for pipelines that don’t demand the complexity or expense of higher-offset designs. They’re frequently used in:

- Municipal and industrial water distribution systems

- HVAC systems with water or glycol

- Low- to medium-pressure process water systems

- Non-critical utility applications with moderate cycling and clean media

In oilfield surface systems, such as produced-water handling or low-pressure gathering, these valves provide reliable isolation when operated within their specified pressure and temperature limits. For tailored solutions, specialized suppliers like NOVA Petroleum Services / Atokan Drilling Technologies Inc can help identify the right valve for specific pipeline needs.

3. Double-Offset Butterfly Valves

Double-offset (or double-eccentric) butterfly valves are designed with two offsets: the stem is positioned behind the disc’s sealing point and slightly off-center. This setup ensures that the disc only contacts the seat during the final 1°–3° of its 90° rotation. By minimizing friction and wear, these valves are particularly well-suited for higher-pressure applications.

Pressure Rating

These valves are built to handle medium to high pressures. Standard configurations operate within a range of 362 to 928 psi (2.5 to 6.4 MPa). High-performance models, adhering to standards like MSS SP-68, can withstand pressures from 1,450 to 11,600 psi (10.0 to 80.0 MPa). Most designs align with ANSI Class 300 ratings, while double-flanged configurations are often rated for ANSI Classes 300–1000.

Sealing Capability

Thanks to reduced contact between the disc and seat, these valves deliver a tighter shutoff at higher pressures while requiring less operating torque. They commonly feature PTFE or metal-reinforced seats, achieving bubble-tight sealing that meets ANSI/FCI 70-2 Class VI standards for clean liquids and gases. The immediate lift-off of the disc from the seat helps prevent deformation and tearing, issues often seen in concentric valve designs. This makes double-offset valves ideal for both on/off isolation and throttling tasks.

Installation Method

Double-offset butterfly valves are available in three main configurations: wafer, lug, and double-flanged.

- Wafer-style valves are compact and fit snugly between pipeline flanges, offering cost and space efficiency when end-of-line closure isn’t needed.

- Lug-style valves feature threaded lugs, allowing them to be bolted to one or both flanges. This design is particularly useful for maintaining individual pipeline segments while keeping upstream pressure intact.

- Double-flanged valves provide maximum rigidity and precise alignment, making them an excellent choice for large-diameter pipelines or high-pressure systems.

Pipeline Applications

These valves are widely used across various industries. In municipal and utility sectors, they are found in water transmission systems, treatment plants, and wastewater networks, where moderate to high pressures and frequent cycling are common. Their tight shutoff and low torque requirements make them a cost-effective solution for large-diameter pipelines, as smaller actuators can be used.

In industrial settings, double-offset valves are utilized in process water systems, cooling loops, refined product pipelines, and certain chemical processes where seat durability is essential. For oilfield operations involving clean hydrocarbons, produced water, or utility services, companies like NOVA Petroleum Services / Atokan Drilling Technologies Inc (https://novapservices.com) specialize in matching the right valve to specific operating needs.

4. Triple-Offset Butterfly Valves

Triple-offset butterfly valves are a cutting-edge solution, designed with three geometric offsets that ensure the disc contacts the seat only at the point of final closure. This design features seat and disc sealing surfaces machined into matching conical shapes, which eliminates disc rubbing and significantly reduces wear compared to other valve designs.

Pressure Rating

These valves are built to handle medium to high pressures, typically adhering to ANSI Class 150–600 standards. For more demanding applications, some models are rated up to ANSI Class 900–1500, with pressure capacities ranging from roughly 360 psi to over 11,600 psi (2.5 to 80.0 MPa). In cases where larger pipelines or higher pressure classes are involved, double-flanged bodies are often employed to provide the necessary structural strength. While pressure handling is a key feature, the sealing performance of these valves is equally important.

Sealing Capability

The triple-offset design creates a metal-to-metal conical seal that engages without any sliding motion. This ensures a tight shutoff comparable to gate valves, all while maintaining the efficiency of quarter-turn operation. The metal seats, usually crafted from stainless steel or hard alloys with specialized coatings, deliver a bubble-tight, bidirectional shutoff that meets API 598 or ISO 5208 Rate A standards. Many of these valves are also compliant with fire-safe and fugitive-emission standards, making them ideal for hazardous fluid pipelines operating under tough conditions.

Installation Method

Triple-offset butterfly valves are available in wafer, lug, and double-flanged configurations. These installation options mirror those found in other types of butterfly valves but are specifically designed to meet the structural demands of high-performance applications.

Pipeline Applications

Expanding on the capabilities of double-offset designs, triple-offset valves are widely used in applications requiring high-integrity isolation and frequent cycling. They are particularly favored in oil and gas transmission pipelines, refinery and petrochemical units, power plant steam lines, and chemical process systems. These valves are commonly employed as line block valves in high-pressure liquid or gas pipelines, where rapid quarter-turn emergency shutoff is critical. Additionally, they are essential in refinery units for isolating hot hydrocarbons and steam, where metal seats are a necessity. Companies like NOVA Petroleum Services / Atokan Drilling Technologies Inc (https://novapservices.com) frequently incorporate triple-offset valves into their pipeline and production networks to meet the demands of high-performance service conditions.

sbb-itb-325a090

5. Wafer-Style Butterfly Valves

Wafer-style butterfly valves are known for their slim and compact design, which fits snugly between pipe flanges. Bolts surrounding the valve secure it in place, making it a space-saving option with the shortest face-to-face length among butterfly valve types. This design helps reduce both the valve’s weight and the space needed for installation. The valve body typically includes two or four guide holes, which align with standard U.S. flange patterns like ASME B16.5 Class 150, ensuring the disc stays centered during installation.

Pressure Rating

These valves are commonly used in water systems, HVAC setups, and low-to-medium pressure industrial applications. They generally fall within the ANSI Class 125/150 range, handling pressures of up to 200–285 psi at ambient temperatures. While lug-style valves share similar pressure ratings, double-flanged butterfly valves are designed for more demanding tasks and often carry ratings up to ANSI Class 300–600 or higher. For critical operations, such as those in the oil and gas sector, engineers consult specific pressure-temperature rating charts for each valve model to ensure suitability. Once pressure parameters are established, the valve’s sealing capabilities further expand its range of applications.

Sealing Capability

Wafer-style butterfly valves are designed to seal effectively against bidirectional pressures, making them versatile for handling flow in either direction. Their resilient seats, made from materials like EPDM, NBR, or PTFE, provide bubble-tight shutoff, making them ideal for clean liquids such as water, various chemicals, and some hydrocarbons. These valves meet ANSI/FCI or ISO standards for soft-seat shutoff, making them suitable for on/off isolation and moderate throttling where minimal leakage is required. However, for handling gases or more hazardous fluids, engineers often opt for high-performance wafer designs featuring double- or triple-offset configurations with PTFE or metal seats.

Installation Method

The installation process for these valves is straightforward. The valve is centered between mating flanges, and bolts are tightened in a cross/star pattern to evenly compress the resilient seat. Proper alignment is crucial to prevent the disc from coming into contact with the pipe bore or flange faces when opening. One key limitation is that wafer-style valves cannot be used for end-of-line service because they depend on being clamped between two flanges for structural support and sealing. Additionally, since the bolts connect both upstream and downstream flanges through the valve, isolating or removing a wafer valve requires shutting down and depressurizing the entire pipeline section on both sides. This makes maintenance more disruptive compared to lug-style alternatives.

Pipeline Applications

Wafer-style butterfly valves are commonly found in water distribution, wastewater treatment, HVAC/chilled water systems, fire protection loops, and general low-to-medium pressure industrial services. They are particularly well-suited for closed-loop systems, such as building chilled-water circuits or utility water lines, where end-of-line conditions are not expected. In industries like oil and gas or chemical processing, these valves are often used in noncritical lines, secondary isolation, or where the piping is well supported, and pressures are moderate.

This compact design not only saves space but also reduces operational torque, making actuation easier. Their quarter-turn operation requires minimal torque, making them compatible with manual levers, gear operators, and automated actuators (electric or pneumatic) using standard mounting pads. Companies like NOVA Petroleum Services and Atokan Drilling Technologies Inc integrate wafer-style valves into pipeline systems where compactness and cost efficiency are key for utility and secondary flow control applications.

6. Lug-Style Butterfly Valves

Lug-style butterfly valves are equipped with threaded lugs that allow each flange to be bolted independently. This design makes maintenance easier and more efficient since the valve can isolate the downstream piping, enabling its removal or servicing while keeping the upstream system pressurized. This feature provides clear advantages in pressure handling and maintenance flexibility.

Pressure Rating

These valves are available in ANSI/ASME Class 125–300, capable of managing working pressures between 200 and 300 psi, depending on factors like size, material, and operating temperature. This makes them a reliable choice for water distribution, HVAC systems, and industrial utilities. For applications requiring higher pressure performance, lug-style valves with double- or triple-offset internals are recommended, as they meet stricter pressure class requirements. Distributors such as NOVA Petroleum Services / Atokan Drilling Technologies Inc can assist with selecting valves that align with specific pipeline needs.

Sealing Capability

Lug-style butterfly valves often feature resilient seats made from materials like EPDM, NBR, or PTFE, allowing for bubble-tight shutoff that meets ANSI/FCI 70-2 Class VI standards for low-pressure applications. For higher-pressure or temperature settings, high-performance versions with double- or triple-offset designs and metal seats provide excellent sealing capabilities. For water, wastewater, and HVAC pipelines, ductile-iron valves with EPDM seats and stainless steel discs strike a great balance between corrosion resistance, pressure handling (typically up to ANSI 150), and cost-efficiency.

Installation Method

These valves are installed by bolting each flange directly to the valve’s threaded lugs. To ensure proper installation, follow ASME B16.5 or AWWA C207 standards, carefully center the valve, and tighten bolts in a cross pattern to evenly compress the gasket. Before final tightening, confirm smooth 0–90° disc rotation. If the application requires downstream piping to be removed, verify that the valve is rated for end-of-line service at the operating pressure. This straightforward installation process complements their ease of maintenance, making them a practical choice for industrial settings.

Pipeline Applications

Lug-style butterfly valves are particularly suited for industrial pipelines that require frequent or sectional maintenance. They are commonly used in water distribution, HVAC systems, and fire protection networks. In municipal or plant water distribution systems, they allow for isolating specific segments, such as filters or heat exchangers, without shutting down the entire system. Refineries and petrochemical plants use these valves to isolate sections of process utility headers during maintenance turnarounds. In oilfield surface facilities, they simplify operations by allowing sections of produced-water or chemical-injection manifolds to be taken offline while the rest of the system continues running. Compared to wafer valves, which typically require full system depressurization for removal, lug-style valves significantly reduce downtime and streamline fieldwork.

7. Double-Flanged Butterfly Valves

Double-flanged butterfly valves are designed to provide robust structural support and precise alignment, making them ideal for high-pressure scenarios. Their construction features flanges on both ends, allowing them to bolt securely to mating pipe flanges along the entire circumference. This continuous bolting surface ensures a fixed face-to-face dimension, offering stability and alignment that wafer and lug-style valves simply can’t match. The rigid mounting minimizes leakage by ensuring even gasket compression at the joints.

Pressure Rating

These valves are built to handle pressures up to ANSI Class 300 and can even be engineered for ANSI Class 600–1000 applications. It’s critical to match the valve’s pressure class and flange design with the pipeline’s specific needs and any transient conditions. Thanks to their dual-flange design, these valves outperform wafer and lug styles in managing elevated pressures, ensuring safety and reliability throughout their service life.

Sealing Capability

Double-flanged valves are available with resilient seals, such as EPDM or NBR, for water and utility services. For harsher conditions involving high temperatures, pressures, or corrosive media, metal-seated, high-performance designs are the preferred choice. The stable flange mounting enhances sealing performance over time, particularly in critical operations. In industries like oil, gas, and chemicals, metal seats and corrosion-resistant components are often selected, especially when integrated with upstream pumping or artificial lift systems from specialists like NOVA Petroleum Services and Atokan Drilling Technologies Inc. These companies supply pumps and equipment tailored for such demanding environments.

Installation Method

Installing a double-flanged butterfly valve involves bolting each flange to the corresponding pipeline flange using a full set of bolts, nuts, and gaskets. To ensure proper alignment, center the valve carefully to avoid disc contact with the pipeline bore, torque the bolts in a cross pattern, and confirm full disc movement before pressurizing the system. For buried pipelines or large-diameter installations, proper pipe and valve support is crucial to prevent flange stress and potential leaks. Thanks to their defined face-to-face dimension, these valves can be removed and replaced as a single unit without requiring pipe modifications, simplifying maintenance and upgrades during shutdowns.

Pipeline Applications

Double-flanged butterfly valves are the go-to choice for critical, high-pressure, or large-diameter pipelines where stability, alignment, and sealing integrity are non-negotiable. They are commonly used in medium to very large pipelines, typically ranging from 6 inches to 120 inches or more. Their flange configuration effectively supports the heavier valve body and disc assembly, making them ideal for applications like municipal water systems, wastewater treatment plants, power plant cooling systems, and industrial process pipelines. For example, in a 60-inch carbon steel pipeline rated at ANSI Class 150–300, double-flanged, double-offset valves are often employed at key isolation points to manage high flow rates and surge conditions. These valves not only provide the structural support needed for large actuators but also ensure reliable, leak-tight isolation for downstream maintenance, outperforming wafer and lug valves in high-stakes scenarios.

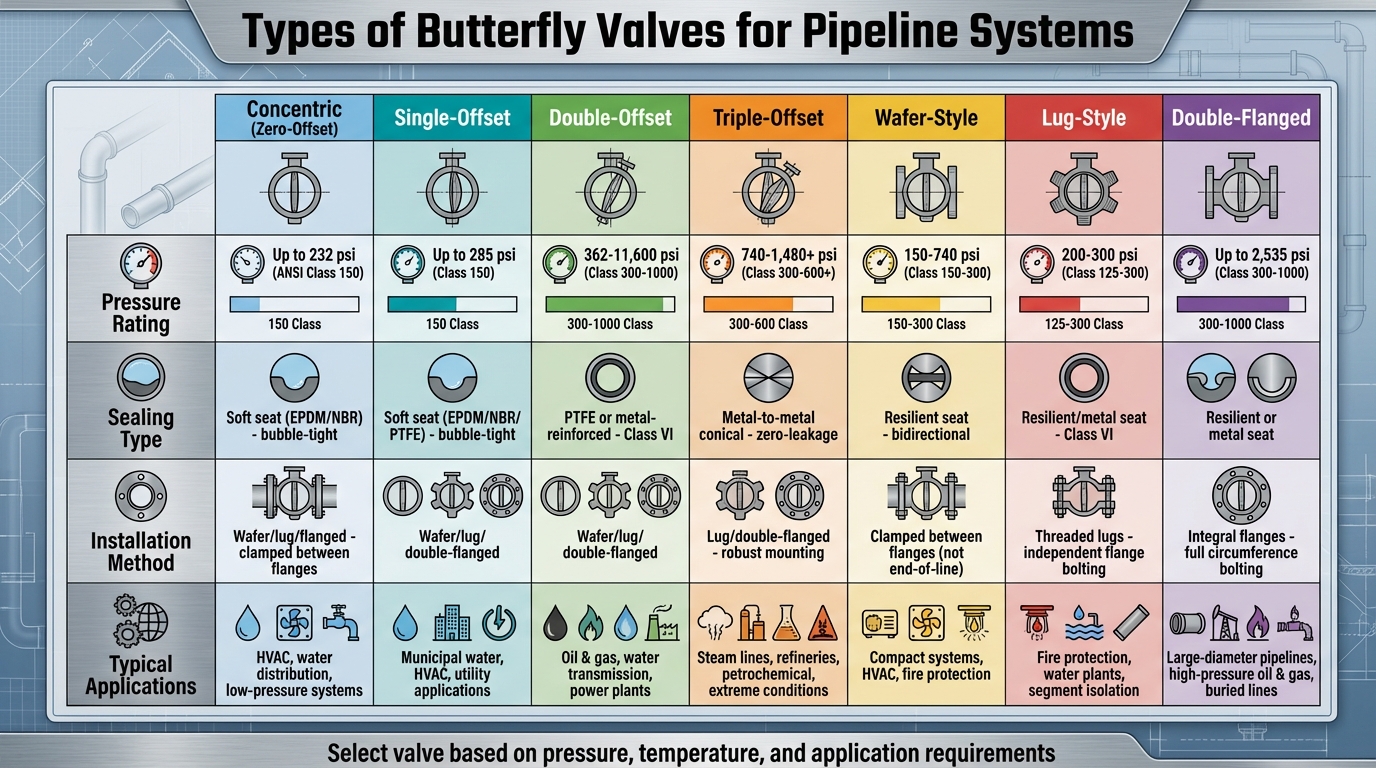

Comparison Table

The table below highlights the main differences among butterfly valve types commonly used in U.S. pipeline systems. Pressure ratings correspond to standard ANSI/ASME classes with approximate psi ranges. Sealing capability describes the seat material and its shutoff performance, while the installation method outlines how the valve connects to piping and whether it supports end-of-line or segment isolation.

| Valve Type | Typical Pressure Rating | Sealing Capability | Installation Method | Typical Pipeline Applications |

|---|---|---|---|---|

| Concentric (Zero-Offset) | Up to ANSI Class 150 (~150 psi) | Soft seat (EPDM, NBR, PTFE) for bubble-tight shutoff | Wafer, lug, or flanged; clamped between flanges | Municipal water distribution, HVAC, low-pressure slurry, building services |

| Single-Offset | ANSI Class 150–300 (~150–740 psi) | Soft or semi-metallic seat with reduced wear compared to concentric | Wafer or lug; similar to concentric but with improved durability | General industrial pipelines requiring extended seat life |

| Double-Offset (High-Performance) | ANSI Class 150–600 (~150–1,480 psi) | Soft or metal seat providing reliable shutoff for higher pressures and temperatures | Wafer, lug, or double-flanged; offers flexible mounting options | Water transmission, power plant cooling, midstream oil & gas, process pipelines |

| Triple-Offset | ANSI Class 300–600+ (~740–1,480+ psi) | Metal-to-metal conical seat for zero-leakage shutoff, bidirectional sealing, and fire-safe performance | Lug or double-flanged; engineered for robust mounting in severe service | Steam lines, refinery and petrochemical isolation, cryogenic and high-temperature gas pipelines |

| Wafer-Style | Up to ANSI Class 150–300 (~150–740 psi) | Seat type varies by design | Clamped between two flanges with through-bolts; not suitable for end-of-line isolation | Pump discharge, compact skid systems, indoor plant piping, HVAC |

| Lug-Style | Up to ANSI Class 150–300 (~150–740 psi) | Seat type varies by design | Threaded lugs bolted to each flange; allows removal of downstream piping | Fire protection zones, water plant headers, industrial lines requiring segment isolation |

| Double-Flanged | Up to ANSI Class 300–1000 (~740–2,535 psi) | Seat type varies by design; often metal-seated for high-pressure service | Integral flanges bolted directly, ensuring precise alignment | Large-diameter water mains, wastewater treatment, buried or high-pressure oil & gas lines |

For low-pressure water and HVAC systems, concentric soft-seated wafer valves are a simple and cost-effective choice. When higher pressure ratings or extended seat life are needed, double-offset valves – configured as lug or double-flanged units – offer better durability and performance. For demanding applications like steam, refining, or petrochemical processes, where high pressure, high temperature, or corrosive conditions are involved, triple-offset metal-seated valves provide zero-leakage shutoff and long-term reliability.

Lug-style valves are particularly useful for isolating and removing sections of a pipeline without depressurizing the entire system. Meanwhile, double-flanged valves are well-suited for large-diameter pipelines, frequent operation, and handling high line loads.

When selecting a valve, be sure to match it to the appropriate ASME pressure class and flange standards (API 609, AWWA C504/C516). For oilfield and process applications, NOVA Petroleum Services / Atokan Drilling Technologies Inc (https://novapservices.com) offers high-quality butterfly valves and pumping equipment from leading manufacturers, supporting both new installations and system upgrades.

Conclusion

Selecting the appropriate butterfly valve for your pipeline system hinges on understanding pressure requirements, operating temperatures, and specific application needs. For low-pressure water and HVAC systems, concentric valves are a practical, cost-effective choice. If you’re dealing with moderate to high-pressure conditions, double-offset valves provide enhanced durability and a tighter shutoff. In the most extreme environments – think high pressures, temperatures ranging from cryogenic levels to over 840°F, or corrosive media – triple-offset valves shine with their zero-leakage, metal-to-metal sealing and low torque operation.

But it’s not just about pressure and temperature. The way a valve connects to your system also plays a big role in performance. Wafer-style valves are a budget-friendly option, ideal for tight spaces. Lug-style valves allow you to isolate sections of the pipeline without shutting down the entire system. Meanwhile, double-flanged valves offer unmatched stability and precise alignment, especially for large-diameter lines and high-pressure applications.

Choosing the right valve doesn’t just improve system reliability – it also cuts down on downtime and operational costs. Each valve type brings unique advantages designed to meet specific engineering demands, helping to ensure your pipeline operates efficiently with minimal maintenance.

When it comes to integrating these solutions into your pipeline, working with experienced partners makes all the difference. For oilfield and industrial applications, NOVA Petroleum Services / Atokan Drilling Technologies Inc (https://novapservices.com) supplies butterfly valves and production equipment from top manufacturers across the USA, Canada, UK, and the European Union. With 140 years of manufacturing expertise behind them, they offer solutions for new installations, system upgrades, and equipment replacements, ensuring your pipeline performs reliably in even the toughest conditions.

FAQs

What are the key differences between concentric and double-offset butterfly valves?

Butterfly valves come in different designs, each suited for specific applications. Concentric butterfly valves feature a disc that aligns perfectly with the pipe’s axis. This straightforward design works well for general-purpose systems where a tight shutoff is necessary. They are an affordable choice, especially for systems operating under lower pressure and temperature conditions.

On the other hand, double-offset butterfly valves take a more advanced approach. With the disc positioned slightly off-center from both the pipe’s axis and the seat, this design reduces contact between the disc and the seat during operation. The result? Less wear and tear, a longer lifespan, and enhanced sealing performance. These valves are ideal for handling higher-pressure and higher-temperature environments, making them a reliable option for more demanding applications.

What makes triple-offset butterfly valves suitable for extreme temperatures and pressures?

Triple-offset butterfly valves are built to handle extreme temperatures and pressures with reliability. Thanks to their advanced offset design and precision-engineered sealing system, they minimize wear while ensuring a tight, leak-free shutoff, even in the toughest operating conditions.

Made from tough materials like stainless steel, alloy steel, or equipped with specialized coatings, these valves can withstand temperatures over 1,000°F and pressures as high as 3,000 psi. This sturdy construction and smart design make them a go-to choice for critical pipeline applications where both durability and performance are non-negotiable.

What are the advantages of choosing a lug-style butterfly valve over a wafer-style valve?

A lug-style butterfly valve provides more versatility during maintenance and installation compared to its wafer-style counterpart. Its design allows it to be securely bolted to pipeline flanges, enabling one side of the pipeline to be disconnected without disturbing the other side or needing to remove the valve entirely.

This feature is particularly advantageous in systems that require regular maintenance or where isolating specific sections of the pipeline is necessary. On top of that, lug-style valves are sturdier and capable of handling higher pressure levels, making them well-suited for more demanding applications.